NaN / 0

aluminum radiator brazing vacuum furnace made in china

Get Latest Price

US$ 70000

≥1 Pieces

Quick Details

Place of Origin:

Shanghai, China

Brand Name:

SIMUWU

Voltage:

380V

Dimension(L*W*H):

custom made

Product Details

aluminum radiator brazing vacuum furnace made in china

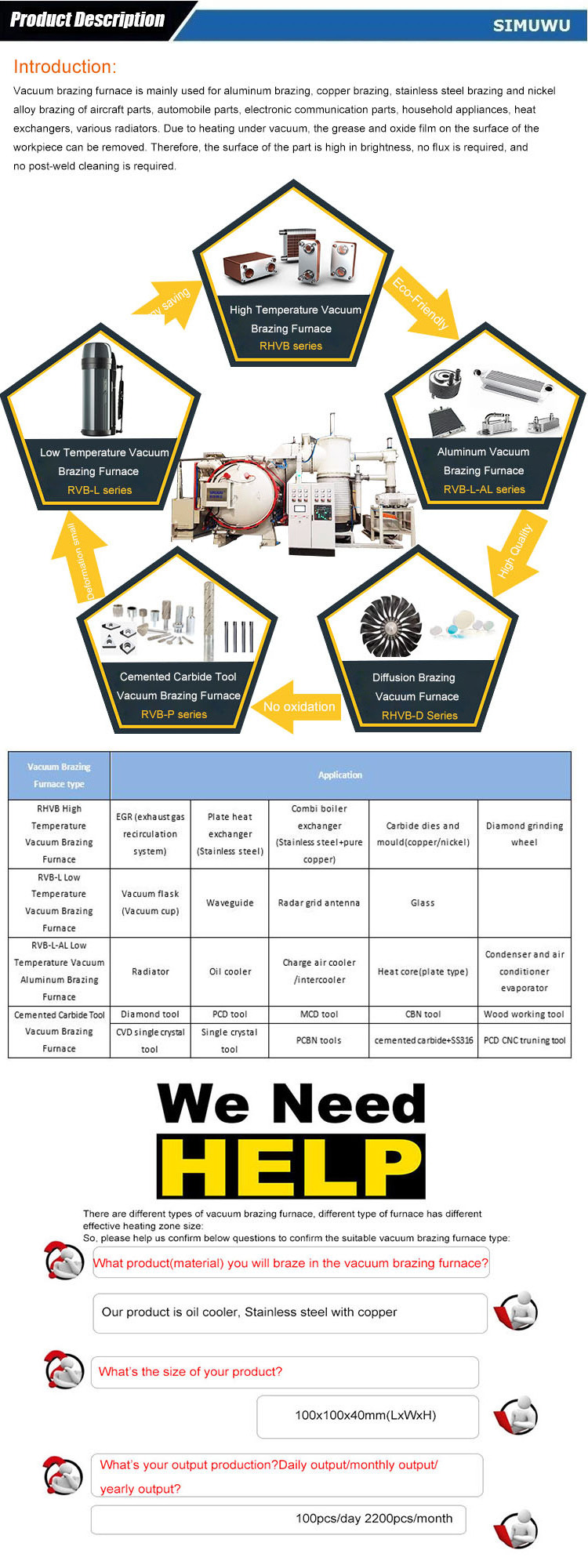

Product Description

You can click here to inuqiry engineer about details!

Let's Introduce our SIMUWU Furnace to you!

You can click here to inuqiry engineer about details!

vacuum aluminum brazing furnace for auto parts and aviation parts

Vacuum brazing is carried out in the absence of air, using a specialized furnace, and delivers significant advantages: extremely clean, flux-free braze joints of high integrity and superior strength. Improved temperature uniformity when heating in a vacuum, and lower residual stresses due to slow heating and cooling cycle, results in significantly improved thermal and mechanical properties of the material. Other benefits of vacuum brazing include heat treating or age hardening of the work piece as part of the metal-joining process, all in a single furnace cycle. Like conventional brazing, vacuum brazing is easily adapted to mass production.

-No oxidation, no weld flux, no pollution, no air hole;

-Low temperature brazing, high temperature brazing, continuous brazing;

-It works on Titanium (Ti), Zirconium (Zr), Niobium ( Nb), Molybdenum (Mo) refractory metal alloys and dissimilar metals too;

-High automation, easy operation, easy maintain.

The equipment with Intelligent control system PLC

|

Name |

Parameter |

|

High temperature vacuum soldering furnace |

Brazing usage / soldering usage |

|

Model |

Horizontal / Vertical |

|

Ultimate vacuum |

Custom made |

|

Pressure rising rate |

0.5pa/h |

|

Max temperature |

Custom made |

|

Temperature uniformity |

±3℃ / ±5℃ |

|

Heating power |

Custom made |

|

Temperature control method |

Intelligent programmable temp controller |

|

Control method |

PLC auto/manual interlock protection |

|

Max gas charging pressure (absolute pressure) |

Custom made |

Specification

|

Main technical data of high temperature vacuum brazing furnace |

|||||

|

Model |

Effective working dimension (mm) |

Max temperature (C) |

Ultimate pressure (pa) |

Pressure rising rate (pa/h) |

Temperature uniformity (C) |

|

RVB-459 |

450x450x900 |

1300 |

8.5x10 -4 |

0.5 |

±3 |

|

RVB-559 |

500x500x900 |

1300 |

8.5x10 -4 |

0.5 |

±3 |

|

RVB-669 |

600x600x900 |

1300 |

8.5x10 -4 |

0.5 |

±3 |

|

RVB-6612 |

600x600x1100 |

1300 |

8.5x10 -4 |

0.5 |

±3 |

|

RVB-7712 |

700x700x1200 |

1300 |

8.5x10 -4 |

0.5 |

±5 |

|

RVB-8716 |

800x700x1600 |

1300 |

8.5x10 -4 |

0.5 |

±5 |

|

Custom-made |

Custom-made |

Custom-made |

Custom-made |

Custom-made |

Custom-made |

Click here for more informations!

Application

· Automobile industry (SCR brazing-Selective Catalyst Reduction, EGR brazing-Exhaust Gas Recycle, oil radiator brazing, plate fin oil cooler brazing, heat exchanger brazing)

· Aviation industry (Aero engine parts, honeycomb seal ring brazing, cellular brazing, engine fuel manifold brazing, stainless steel heat exchanger brazing, compressor stator brazing, Inconel alloy parts brazing)

· Air separation plant (impeller brazing, compressor intercooler brazing, regenerator brazing)

· Engineering machinery ( bit brazing, diamond tools brazing)

Click here for more informations!

Hot Searches