NaN / 0

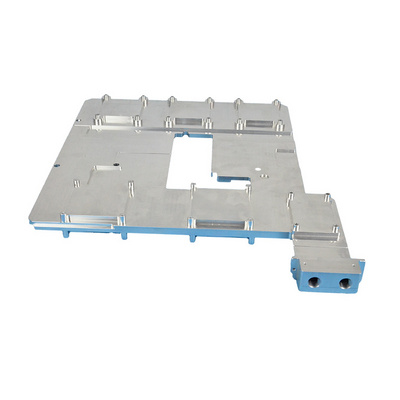

Professional Factory Made Gas-carrier Heating Aluminum Vacuum Brazing Furnace For Engineering Machinery Heat Exchanger

Get Latest Price

US$ 51953.6

≥1 Pieces

US$ 47500

≥5 Pieces

Quick Details

Place of Origin:

Jiangsu, China

Marketing Type:

Hot product

Warranty of core components:

1year

Brand Name:

Sifang

Product Details

|

vacuum gas-carrier heating aluminum brazing furnace

|

|

|

|

|

|

|

|

|

||||||||

|

Model

|

Valid zone(mm)

|

Maximum temperature (℃)

|

Temperature uniformity (℃)

|

Installed power

(KW)

|

Ultimate vacuum (Pa)

|

Pressure rising rate(Pa/h)

|

Installed furnace capacity( KG)

|

Gas cooling pressure (bar)

|

||||||||

|

ZLQ-300ZQ

|

2400x800x800

|

750

|

±4

|

330

|

4x10-1

|

0.5

|

2000

|

2

|

||||||||

|

ZLQ-350ZQ

|

2400x1000x1000

|

750

|

±4

|

380

|

4x10-1

|

0.5

|

500

|

2

|

||||||||

|

ZLQ-ZQ series vacuum gas-carrier heating aluminum brazing furnace is mainly used in the vacuum gas-carrying blazing furnaces of engineering machinery heat exchanger, hydraulic pump station heat exchanger, automotive heat exchanger and other plate-fin heat exchangers.

The low vacuum constant pressure inert gas protects and replaces the high vacuum aluminum brazing, which has shortened the vacuum time and raised the parts heating rate. The heat stirring fan has ensured the uniformity of furnace temperature and the uniformity of constant pressure inflation. |

|

|

|

|

|

|

|

|

||||||||

|

Outer circulating cooling fan has improved the cooling rate and shortened the discharging time.

The analog plate automatic control or the IPC automatic control are optional. The working cycle is approximately 3.5 hours(high vacuum brazing 8 hours) The power consumption of the single furnace is about 450 degrees(high vacuum aluminum brazing 800~1200℃), energy consumption uses the real-time monitoring. |

|

|

|

|

|

|

|

|

||||||||

1.Q: Are you a factory or trading company?

A: We are a factory and we have professional team of workers,Designers and inspectors.

2.Q:Do you accept custom?

A:Of course.We have professional teams who make your designs,photos,

imagines and OEM orders into real production.

3.Q:What’s your advantages?

A: Quick response to your enquiry,

High quality control,

Reasonable price,

Timely delivery,

Excellent after-sales service,

OEM/ODM are welcome

4.Q:What’s your shipping terms?

A:If you need to ship by air,we can use DHL,UPS,FedEx,TNT or EMS.If you need to ship by sea,we have many good forwarders to work

with,they can provide the best price for you.

A: We are a factory and we have professional team of workers,Designers and inspectors.

2.Q:Do you accept custom?

A:Of course.We have professional teams who make your designs,photos,

imagines and OEM orders into real production.

3.Q:What’s your advantages?

A: Quick response to your enquiry,

High quality control,

Reasonable price,

Timely delivery,

Excellent after-sales service,

OEM/ODM are welcome

4.Q:What’s your shipping terms?

A:If you need to ship by air,we can use DHL,UPS,FedEx,TNT or EMS.If you need to ship by sea,we have many good forwarders to work

with,they can provide the best price for you.

Hot Searches