NaN / 0

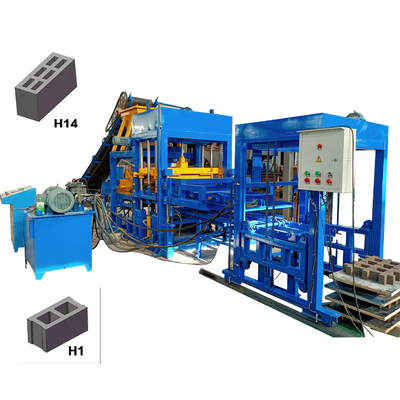

Fully automatic hollow concrete block making machine

Get Latest Price

US$ 1790

≥1 Pieces

Quick Details

Type:

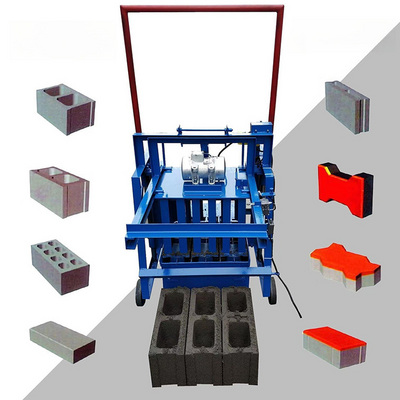

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Autoclaved aerated concrete block (AAC)

Brick Raw Material:

Clay

Production Capacity (Pieces/8 hours):

4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours

Brick size:

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

Product Details

Product Description

This type of brick making machine is developed by combining the advantages of several other manual brick making machines. The machine adopts spring buffer to reduce wear and increase mold pressure, thereby increasing block forming speed, increasing block density and reducing raw material consumption. It requires workshop AERA 30-50CBM and land AERA 200-400CBM. It only requires 2-3 workers to produce, and the investment is low, so this manual hollow block machine is very suitable for factories or family businesses.

Working principle of concrete block molding machine brick making:

This brick machine is based on the technical transformation of the original block forming machine. The original primary vibration is changed to the secondary vibration of the mold core, which makes the block density higher, the molding speed faster, and the block strength is more uniform. It is suitable for Any customer who has a block making machine. Existing cement workplaces and pallets consumed can be reduced

Dimensions 1500*1335*1580 mm

Molding cycle 45s

Main form of vibration platform vibration

Total power 7.4kw V

ibration frequency 4600 (r/min)

The production blocks can be widely used: coal gangue slag, sand gravel, a luminum electrolytic copper red slag, construction waste, fly ash slag and other raw materials. The raw materials are abundant and can be seen everywhere.

Contact Us

Packaging & Shipping

Hot Searches