NaN / 0

Fully automatic multi-functional fully automatic concrete block making machine paving block making machine

Get Latest Price

US$ 2690

≥1 Sets

US$ 2550

≥6 Sets

US$ 2400

≥12 Sets

Quick Details

Type:

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

Brick Raw Material:

Cement

Production Capacity (Pieces/8 hours):

7600~53000 Pieces/day

Brick size:

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

Product Details

Product Overview

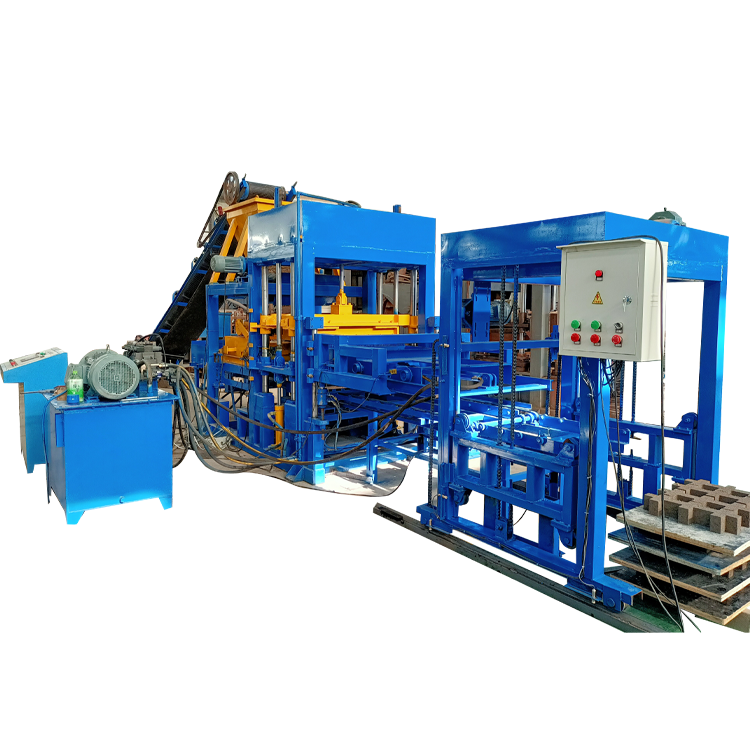

QTY4-15 automatic hydraulic block molding machine

Model QTY4-15 automatic hydraulic block molding machine, belongs to automatic brick making machine, molded by hydraulic pressure. By changing the mold, it can produce various shapes of bricks such as hollow bricks, porous bricks and pavement bricks. It is characterized by low investment and high efficiency.

Technical parameters

|

Molding cycle

|

15-20s

|

|

Vibration frequency

|

4000-4200 times/sub

|

|

Installed capacity

|

22KW

|

|

Excitation force

|

22KN

|

|

Weight

|

4200KG

|

|

Overall Dimension

|

6000×1620×2500mm

|

|

Pallet size

|

950×550×35mm

|

Product advantages

1.Fully automatic ,very easy operated by workers, greatly reduce the labor-cost.

2.Japan Mitsubishi PLC control system, ensure the machine runs extremely smoothly, long serving life. Faults-displaying and the

troubles-shooting on the cabinet.

3.Wear-resistant, high toughness, high strength

4. A multi-purpose machine, by replacing the mold can produce different bricks

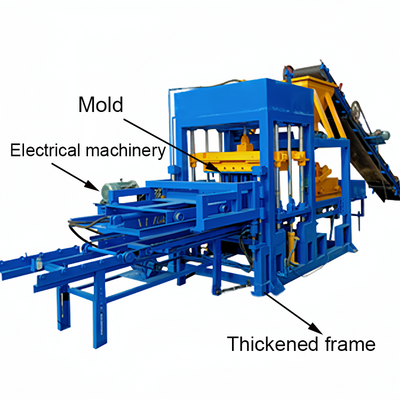

Detail Images

The brick making machine produced by our company saves manpower and material resources, saves cost, the equipment has high precision, there are many kinds of brick making machine, which can meet the different needs of customers, and it can be used for multiple purposes in production, and various shapes of bricks can be produced by replacing the customized mold.

QTY4-15 automatic hydraulic block molding machine, using hydraulic pressure, while the machine adopts thickened frame, making the work more safe and reliable, producing bricks with good strength and high density.

Raw Material

The raw materials of QTY4-15 automatic hydraulic block molding machine are easy to get. The raw materials for production are crushed stone powder, sand, stone and cement, and can be added in large quantities of fly ash, slag, steel slag, coal gangue, ceramics, perlite and other industrial waste residues. The brick making machine has a wide range of raw materials to choose from and is widely used.

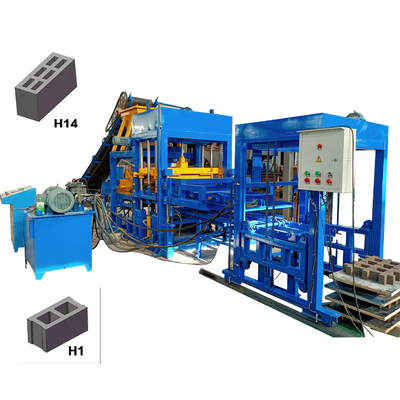

Sample brick display

Model QTY4-15 automatic hydraulic block molding machine produces different bricks by replacing different molds, which can be customized according to customers' requirements.

About us

We are a professional seller of brick making equipment, and our products are exported to domestic and abroad with guaranteed quality and reliable price. Our products include fully automatic and semi-automatic brick making machines, as well as stationary and mobile brick making equipment. Such as QTY10-15 automatic block molding machine, QTYQ8-15 block molding machine production line, QTY6-15 automatic hydraulic block molding machine production line, QTY5-20B multifunctional hydraulic molding machine, QTJ4-25 automatic fabric block molding machine and so on, please feel free to consult us.

FAQ

Q1:H

ow can we guarantee quality?

A1:Always a pre-production sample before mass production;Always final Inspection before shipment.

Q2: What are the advantages of this machine?

A2:QTY4-15 full-automatic brick making machine with high efficiency and excellent brick making quality.

Q3:What kind of payment methods do we accept?

A3:Accepted payment methods: T/T,L/C,D/P D/A,MoneyGram,PayPal.

Hot Searches