NaN / 0

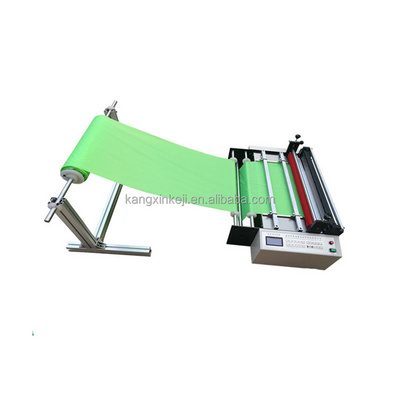

Automatic Paper Cutting Machine Roll to Sheet Die Cutter For Paper Products

Get Latest Price

US$ 35000

≥1 Sets

Quick Details

Type:

Die-cutting Machine

Production Capacity:

180 m/min

Max. workable width:

1150mm

Place of Origin:

Zhejiang, China

Product Details

RD970/1150 Roll D ie C utting M achine

Roll die cutting machine is widely used in the area of the roll printing, packaging, paper cups and so on .It is suitable for kinds of cigarette boxes, medical boxes, envelope, paper cups, paper bowels, gift bags and the other paper and plastic products. The main electric part and opponents of the machine adopts imported ones, It adopts the structure of worm gear, can make the products of high quality, low depletion, high security. The machine controls the feeding automatically, color mark tracking, and die cutting accurately, knife plate locking pneumatically, easy operating and changing.

Features:

1. W orm wheel and worm transmission system ensures the powerful and steady pressure and makes the cutting accurately while the machine runs with high speed, has features of low noise, smooth running and high cutting pressure .

2. The pressure is automatic adjusted through the motor to control by HMI. It can accurate and fast to achieve die-cutting pressure adjustment.

3. Electrical control system:adopts micro computer control, photoelectric chase and detect, achieving from paper feeding,convey, die-cutting and delivering process automatic control and detect.

Main Technical Parameters:

|

Model |

RD 970 /RD1150 |

|

|

1 |

Cutting Precision |

± 0.1mm(white paper) |

|

2 |

Rated Cutting Speed |

120-180times/min |

|

3 |

Max Cutting Pressure |

320T |

|

4 |

Max Cutting Paper Size(W × L) |

940mm*510mm(W × L) / 1120 mm* 6 10mm(W × L) |

|

5 |

Min Cutting Paper Size(W × L) |

400mm*350mm (W × L) |

|

6 |

Suitable Paper Weight |

100g-500g |

|

7 |

Total Rate Of Machine |

16Kw |

|

8 |

Overall Dimensions |

4600x2800x2300mm(LxWxH) 4.6m*2.8m*2.3m (L × W × H)4.6m*2.8m*2.3m (L × W × H) |

|

9 |

Total Weight |

7500kg |

Advantages:

1. Save 15% material compared to flat paper

2. High efficiency, the speed can reach 150 times per minute, and the maximum can reach 180 times per minute

3. Energy saving, the machine power is only 16Kw

What can we do for you?

What machines can we offer?

Warranty?

Installation and training?

What''s the delivery time?

How to confirm the quality of machines?

Hot Searches