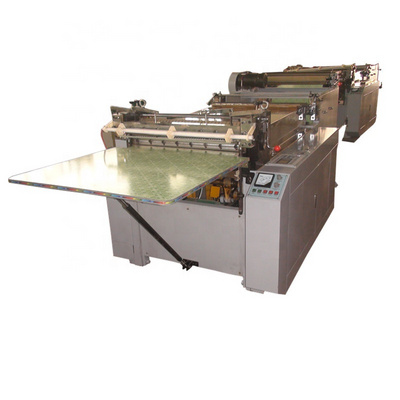

Special cutting tools

Special mechanical structure and special cutting tools, with professional software control to completely solve the problem of

uneven incision and achieve the incision level/degree of accuracy.