NaN / 0

SMCLM-10B-AT Automatic Plastic PVC RFID Smart ID Card Laminating Making Machine

Get Latest Price

US$ 50000

≥1 Sets

Quick Details

Place of Origin:

GUA

Brand Name:

SmartManufacture

Voltage:

380V

Power:

45KW

Product Details

Product Description:

SMCLM-11B-ATA Automatic Loading & Transfer Smart Card Laminator is automatic load trays with materials upto each daylight, automatic transfer trays with materials from hot tower to cold tower, the automatic functions are specially made because of big size materials with trays with plates will be over 60KGS for A2 size, but now even a young girl without strong power can operate machine well.

Operation Steps:

1.Just for the first time , two operators need to take tray with materials into the loader.

2.Choose the setting by touch-screen to automatic move up tray with materials to each daylight by servo system.

3.Push trays into hot lamination tower and press "start hot lamination" switch.

4.After hot lamination , hot lamination daylights automatic open and press "transfer" switch, automatic transfer trays from hot lamination daylights to cold lamination daylights, and the automatic transfer module automatic back to origin position.

5.Press "start cold lamination" switch for cold lamination.

6.At the same time laminate another 10 trays for hot lamination.

7. When cold lamination finish, operator take each tray out from cold lamination daylights and get laminated sheets, at the same time put new materials into trays on the loader, no need to take out plates and pad, save time and save labour, no need strong man to do this job.

Configurations:

1. Separate two softwares: one software to control trays automatic loading up and down to all lamination daylights, another software to control hot daylights lamination and cold daylights lamination with time & pressure & temperature setting.

2. Separate two oil hydraulic system: hot tower and cold tower are maximum 80Tons pressure and maximum 12 steps pressure for inlay & RFID & dual interface card production.

3. Separate temperature control module: can turn ON / OFF any plate temperature for sample card production, the real temperature and setting temperature difference only less than 5 degrees. Maximum temperature setting can be 400C, perfect for PVC, PET, PETG, Teslin, Polycarbonate, ABS or other materials.

4. Can save the parameters setting and output for different types card production.

Technical Specifications:

Voltage: 380V 50/60Hz

Power: 40KW

Air Supply: 0.6-0.8MPa 6KG per square centimeter around 20L/minute

Control Method: Omron PLC + Mitsubishi Servo System + Weinview Touch Screen

Lamination Materials Type: PVC, PET, PETG, Teslin, Polycarbonate, ABS or other materials

Lamination Size: Maximum 7*8 format or other format by your order

Temperature Range: maximum 400C

Pressure Range: maximum 80Tons

One Time Pass Rate: 99.9%

Dimensions: 3080mm*2400mm*1620mm

Weight: 3500KGS

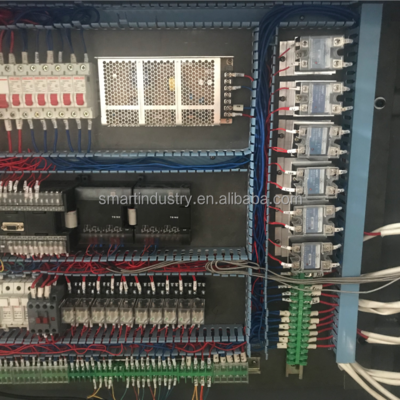

Omron PLC + Temperature Modules Separate Oil Hydraulic Control

Outer Automatic Loading Trays Touch-Screen Operation

Packaging & Shipping:

All our machines are packed by standard export wooden box, we can ship goods by our forwarder or your shipping agent.

Our Services & Company Certificates & Information:

Customers Main FAQ:

Question:Your company is trading company or factory?

Answer: We are factory. We have our workshop and 23 workers and professional 6 engineers just for machines installation and 1 software engineer if customers need special requirements of machine. We are Factory, so we have cost advantage than others, we can offer support on time.

Question:How do your company control the machine quality?

Answer: First we control the raw materials quality.

Second, we control the quality of machine when we are processing.

Third, Our installment engineers will continue test machine minimum 3days.

Question:How about payment term, payment safety and delivery time?

Answer:We accept advance deposit, balance before shipment. And Irrevocable L/C at sight. Anybody can come to check machines when machines ready. Delivery time is 20 to 60

days. It is according to order quantity and if customized products.

Question: What is your company after sale service?

Answer: Our installment engineers are available. Normally it will take about 7 to 10 days for all.

Our guarantee is 1-2 year. If there is any spare parts is broken, we can send them freely to you by our DHL or FedEx account.

Hot Searches