NaN / 0

Plastic ID Card PVC Bank Card Film Lamination Machines Laminating Machine Business Card Making Machine

Get Latest Price

US$ 32000

≥1 Sets

US$ 25000

≥5 Sets

Quick Details

Packaging Type:

case

Packaging Material:

Wood

Driven Type:

Hydraulic

Voltage:

220V/380V 50/60Hz

Product Details

Product Description

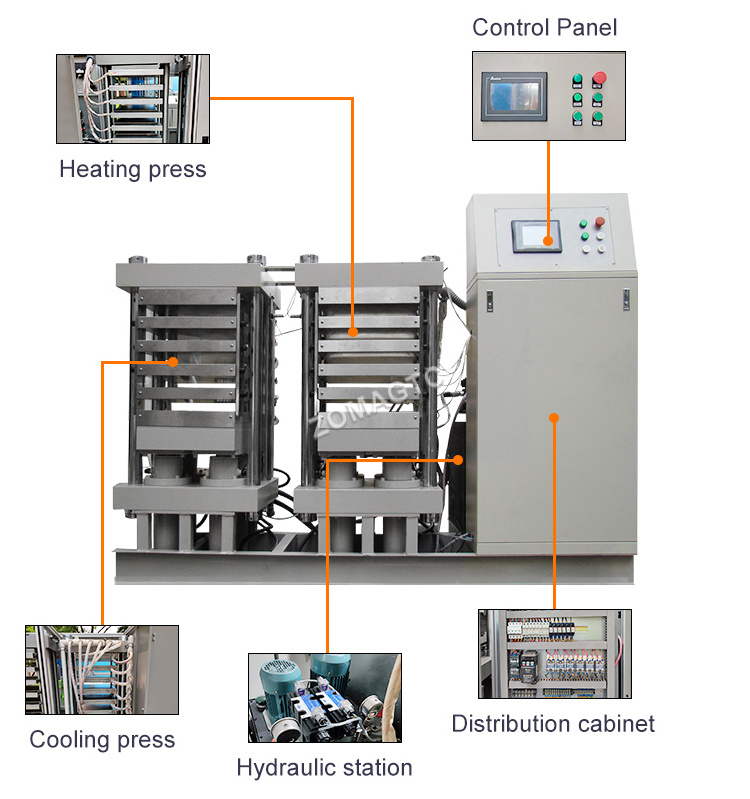

PVC ID card Lamination Machines Plastic Id card Making Machine Machine for make pvc card

PVC ID Card Lamination Machines P

lastic Id card Making Machine B

ank Card

Machine for Make PVC Card

PVC ID card Lamination Machines Plastic Id card Making Machine Machine for make pvc card

|

Heat cool structure

|

Double towers: Right heat, Left cool

|

|

|

Control method

|

PLC automatic control, have PLC and HMI, Have PID control temperature mode

|

|

|

Press plate size

|

550*640mm

|

|

|

For cards layout

|

4*8, 3*8, 5*5

|

|

|

Press plate material

|

Default standard is No.45 steel, Optional aluminum alloy

|

|

|

Opening QTY

|

Right 7 heat + Left 7 cool

|

|

|

Opening space

|

50 mm

|

|

|

Sheets in 1 opening

|

Normally 10 layers of sheet in 1 opening, maximum 15 layers, depend on sheets thickness

|

|

|

Pressure method

|

Hydraulic

|

|

|

Cylinder QTY & diam.

|

8*100 mm

|

|

|

Cylinder stroke

|

280 mm

|

|

|

Oil tank capacity

|

150 L

|

|

|

Hydraulic Oil Grade

|

No. 46 anti-wear hydraulic oil

|

|

|

Hydraulic pressure

|

0.8-15 MPa

|

|

|

Pressure accuracy

|

±0.3 MPa

|

|

|

Pressure grade

|

Heat pressure can set 1-8 grades; Cool pressure can set 1-4 grades

|

|

|

Pressure buffer springs

|

Yes

|

|

|

Heating method

|

Electric heating tube

|

|

|

Heating temperature

|

≤250°C

|

|

|

Temperature accuracy

|

±1.0°C

|

|

|

Cooling method

|

Water circulation cooling

|

|

|

Cooling tool

|

8 or 10 HP water chiller

|

|

|

Power

|

22 kW

|

|

|

Power supply

|

AC380V 50/60HZ

|

|

|

Machine Dimension

|

2400*1000*1500 mm

|

|

|

Machine weight

|

3500 KG

|

|

Recommend Products

Contact us

Packaging & Shipping

PACKAGING

|

Packaging Details

|

|

Stong wooden box package

|

|

|

Port

|

|

The main ports in China, depends customers choice

|

|

|

Lead Time

|

1 pc

|

35 days

|

|

|

|

>1 pcs

|

To be negotiated

|

|

SHIPPING

1.By air, sea or combined transportation.

2.Express via FEDEX, TNT, UPS, DHL, EMS(AS your request)

3.Tracking Number will offer you immediately after delivery

3.Tracking Number will offer you immediately after delivery

4.Shipping cost depends on the shipping method, product quantity,weight, carton size and your area.

Hot Searches