NaN / 0

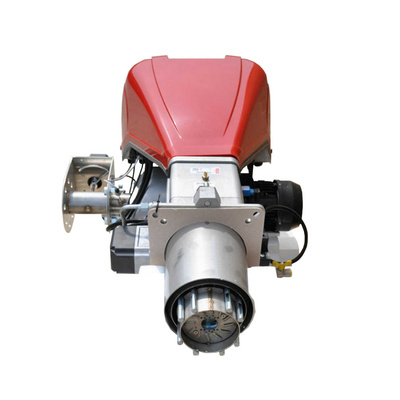

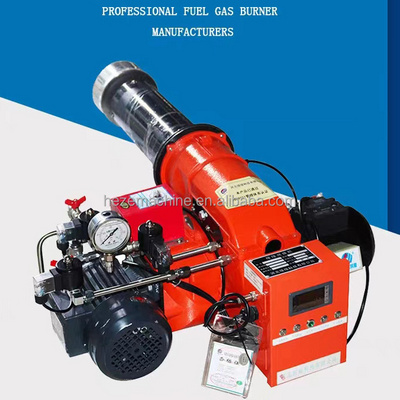

Small Gas Boiler Burners Waste Oil Burner For Heating Boilers

Get Latest Price

US$ 315

≥1 Sets

US$ 241

≥5 Sets

US$ 175

≥10 Sets

US$ 155

≥100 Sets

Quick Details

Type:

Oil Burner

Weight (KG):

16

Place of Origin:

Henan, China

Brand Name:

BNTET

Product Details

Products Description

|

Product Name

|

Boiler Burner/Industrial Burner

|

|

|

Type

|

Waste Oil Burners

|

|

|

Applicable Fuel

|

Waste Oil

|

|

|

|

Boliers eqyuonebtm, hot blast stoves, drying applications, dryers, industrial kilns, furnaces, incinerators, calcining,equipment,ovens,spraying,ironing,power plants, metallurgy, steel, food processing and other industries that use thermal energy equipment.

|

|

|

Can be customized according to customer needs.

|

|

|

|

Models of Heavy Oil Burners

|

|

|

|

|

|

|

||||||

|

Burner Model

|

Power

(kw)

|

Heavy oil flow(kg/h)

|

Power Supply

|

Motor Power

(kw)

|

Packing Size

L x P x H(mm)

|

Weight

(kg)

|

||||||

|

BNH 10 G

|

340-1040

|

30-93

|

3N 380V 50Hz

|

1.1

|

970x700x900

|

151

|

||||||

|

BNH 20 G

|

670-2050

|

60-183

|

3N 380V 50Hz

|

3

|

1140x800x990

|

185

|

||||||

|

|

|

|

|

|

|

|

||||||

|

BNH 75 F

|

446 ~ 837

|

40 ~ 75

|

3N 380V 50Hz

|

1.1

|

1450x830x815

|

108

|

||||||

|

BNH 100 F

|

558 ~ 1116

|

50 ~ 100

|

3N 380V 50Hz

|

1.5

|

1450x830x815

|

116

|

||||||

|

BNH 120 F

|

669 ~ 1451

|

60 ~ 130

|

3N 380V 50Hz

|

2.2

|

1450x830x815

|

170

|

||||||

|

BNH 180 F

|

725 ~ 2009

|

65 ~ 180

|

3N 380V 50Hz

|

3

|

1450x830x815

|

195

|

||||||

|

BNH 250 F

|

937 ~ 3170

|

80 ~ 280

|

3N 380V 50Hz

|

7.5

|

1620x1200x960

|

255

|

||||||

|

BNH 300 F

|

1220 ~ 3460

|

109 ~ 310

|

3N 380V 50Hz

|

7.5

|

1620x1200x960

|

295

|

||||||

|

BNH 350 F

|

1284 ~ 3907

|

115 ~ 350

|

3N 380V 50Hz

|

9

|

1620x1200x960

|

305

|

||||||

|

BNH 600 F

|

1840 ~ 5500

|

165 ~ 490

|

3N 380V 50Hz

|

15

|

1620x1200x960

|

325

|

||||||

Technological performance and structural descriptions:

1. Waste oil burner.

2. Two-stage sliding/modulating/electronic working.

3.Air atomizing.

4. Ability to obtain optimal combustion values by regulating combustion air and blast-pipe.

5. Maintenance facilitated by the fact that the atomisation unit can be removed without having to remove the burner from the boiler.

6.Sliding/modulating Minimum and maximum air flow regulation for first and second stage by means of electric servomotor with pause closure of gate to prevent any heat dispersion to fuel.

7. Electronic with two servo motor control the proportion of fuel and air regulation.

8.Pauses burner,air door closed in order to reduce heat loss in the future.

9.The servo motor which fixed with a cam can adjust the consumption for fuel and air.

10.It adapts one flange and heat-resistance insulated pad to connect with boiler.

11.Burner air inlet with mute design.

12.High temperature resistant stainless steel disc burner flame.

13.Independent of the heavy oil electric heater set and three-phase motor to drive pump.

14. Flame presence check by photo resistance.

15. Electrical plant protection rating Ip40.

3.Air atomizing.

4. Ability to obtain optimal combustion values by regulating combustion air and blast-pipe.

5. Maintenance facilitated by the fact that the atomisation unit can be removed without having to remove the burner from the boiler.

6.Sliding/modulating Minimum and maximum air flow regulation for first and second stage by means of electric servomotor with pause closure of gate to prevent any heat dispersion to fuel.

7. Electronic with two servo motor control the proportion of fuel and air regulation.

8.Pauses burner,air door closed in order to reduce heat loss in the future.

9.The servo motor which fixed with a cam can adjust the consumption for fuel and air.

10.It adapts one flange and heat-resistance insulated pad to connect with boiler.

11.Burner air inlet with mute design.

12.High temperature resistant stainless steel disc burner flame.

13.Independent of the heavy oil electric heater set and three-phase motor to drive pump.

14. Flame presence check by photo resistance.

15. Electrical plant protection rating Ip40.

Product Show

Other Type Burners

Gas Burner

Diesel Oil Burner

Waste Oil Burner

Heavy Oil Burner

Dual Fuel Burner

Customizable

Industrial Burners

for industrial furnaces and firing systems in the iron and steel industries in the precious, non-ferrous and light metal sector, as well as in the plastics, fibre and paper industries.other fields of application are thermal incineration installations, as well as driers and hot air generators.

High Speed Burner

applications:tempering furnaces, hardening furnaces, reheating furnaces, fluidized bed driers, thermal oxidizers, non-ferrous melting, ladle/tundish,glass lehrs,environmental applications, and preheated air.

Mixing Station Burner

Asphalt mixing plant burners are also called asphalt equipment burners, asphalt industry drying heating burners, etc., asphalt mixing plants, also known as asphalt concrete mixing plants, asphalt concrete mixing plants.

Rotary Kiln Burner

Used in cement kilns, pelletizing kilns, lime kilns, lithium kilns, magnesia kilns, alumina kilns, chromite kilns, beneficiation kilns and other kilns in building materials, metallurgy, chemical industry, electric power and other industries.

Product packaging

Application