NaN / 0

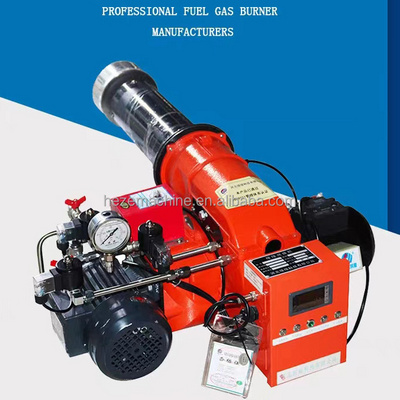

waste oil burner Fuel incinerator Boiler Burner kerosene oven BNTET oil burners

Get Latest Price

US$ 369.6

≥1 Sets

Quick Details

Type:

Gauge

Weight (KG):

30

Place of Origin:

Henan, China

Brand Name:

YUJI

Product Details

Product Description

waste oil burner Fuel incinerator Boiler Burner kerosene oven BNTET oil burners

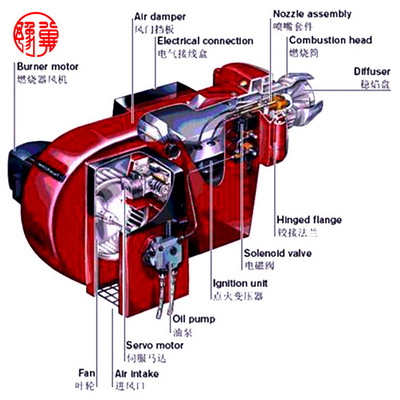

Different from integrated burner, a split burner consists of two modules:

1)Burner fuselage and head;

2)Independent blower.

These two modules are connected by air pipes to form a complete burner system. Benefits of independent blowers:

Blowers can be installed in workshops different from burners, such as basements, which can reduce the noise of boiler rooms. When the blower is installed in the same workshop, it is necessary to make a muffler outside the blower to reduce the noise without blocking the arrangement of the burner.

-Split burner occupies less space in front of the boiler.

-The split burner also reduces the load on the front wall of the boiler.

-The blower can be installed according to any type, and can overcome the resistance of the back pressure or heat exchanger of the combustor by using the existing ventilation equipment, which fully meets the requirements of users and industrial applications.

-The combustion-supporting air can be heated up to 250 degrees, and the operation efficiency of the system can be improved.

1)Burner fuselage and head;

2)Independent blower.

These two modules are connected by air pipes to form a complete burner system. Benefits of independent blowers:

Blowers can be installed in workshops different from burners, such as basements, which can reduce the noise of boiler rooms. When the blower is installed in the same workshop, it is necessary to make a muffler outside the blower to reduce the noise without blocking the arrangement of the burner.

-Split burner occupies less space in front of the boiler.

-The split burner also reduces the load on the front wall of the boiler.

-The blower can be installed according to any type, and can overcome the resistance of the back pressure or heat exchanger of the combustor by using the existing ventilation equipment, which fully meets the requirements of users and industrial applications.

-The combustion-supporting air can be heated up to 250 degrees, and the operation efficiency of the system can be improved.

PS: All TS series burners need to be equipped with a blower. If the regulation ratio is above 1:6, a corresponding motor frequency converter can be configured to increase the regulation ratio to the burner. When the low nitrogen emission requirement is below 30 mg/kWh, a mixing box can be installed at the entrance of the fan. The mixing box is connected with the regulating valve of the flue gas pipeline, and the suction of the blower is used to mix part of the flue gas with air and feed it into the burner. At this time, the nitrogen oxide emissions of the burner will be reduced.

| Material | Cast iron, Cast steel or customer's request |

| Output Power | 17-50KW |

| Size | Customized design |

| Brand | YUJI |

| Remarks | Customized order is also accepted. |

Related Products

Packaging & Shipping

Main Products