NaN / 0

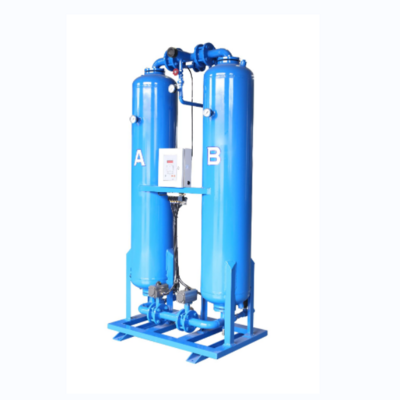

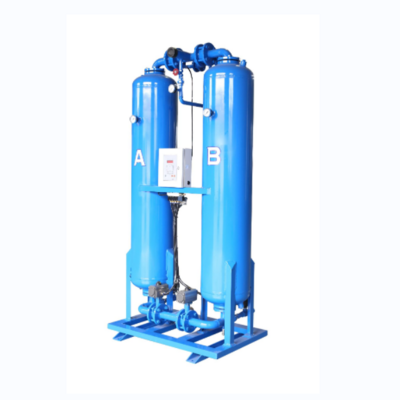

Combined low dew point compressed air dryer machine

Get Latest Price

US$ 1500

≥1 Pieces

Quick Details

Model NO:

SDZF

Transport Package:

Carton or wooden cases

Trademark:

Shanli

Origin:

China

Product Details

Air cooled combined low dew point compressed air dryer

Product picture

Applicable working conditions

Maximum inlet air temperature: 45 ℃

Ambient temperature range: 5 ℃ -50 ℃

Pressure range: 0.6-1.0mpa

Pressure dew point: -20 ℃ ~ -40 ℃

Cooling method: air cooled

Oil content of intake air: ≤ 0.1ppm

Power supply: 1-12nm ³/ min:AC 220V/50HZ

15Nm ³/ Min and above: AC 380v/220v/50hz

Cycle: t=40 (min)

Refrigerant: R22 (R407c/R134a optional)

Design working conditions

Inlet air temperature: 38 ℃

Ambient temperature: 38 ℃

Working pressure: 0.7MPa

Pressure loss: ≤ 5% of design pressure

Note: Air cooled equipment above 80m³/min(including 80m³/min)without canopy

Working principle

The combined low dew point dryer is composed of a refrigerated compressed air dryer and an adsorption (non heated or heated) compressed air dryer through reasonable pipeline connection and volume matching. The refrigerated compressed air dryer has very strong water removal capacity, low operation energy consumption and no air loss. Combined with the adsorption compressed air dryer, which can achieve low dew point, it can give full play to the advantages of both.

Product introduction

Low dew point: the combined low dew point dryer can reach a very low pressure dew point, which can reach below -40 ℃ in general and -70 ℃ at least according to different user requirements;

It can provide compressed air with different dew points for different gas consumption points;

All operating switches of the combined low dew point compressed air dryer and some display instruments of the cold dryer are centralized on the panel of the box plate. The refrigerated compressed air dryer and the adsorption regenerative compressed air dryer can operate independently or simultaneously cold and suction according to the needs of customers;

The gas-liquid separator adopts the self-designed three-stage separation method: direct impact separation + low-speed centrifugal separation + stainless steel wire mesh demisting separation. 99.9% of the liquid water is separated from the cooled compressed air to prevent the secondary evaporation of water and ensure the low dew point quality of the product gas;

The high-quality switching valve is stable and reliable, which can ensure the integrity of the workflow and prolong the working life of components;

The fully or semi enclosed refrigeration compressors of Danfoss (Denmark), Fusheng (Taiwan), Panasonic (Japan), Bitzer (Germany), Copeland (Germany) and MANEUROP(France) are used as the refrigeration compressors, with stable operation, low noise, high cop, reliable performance and long power saving life;

Product specifications

Air cooled low dew point combined desiccant air dryer

Model Item | Air capacity |

| Air connection pipe size | Refrigerating power | Air volume | Fan power(W) | Voltage(V) | Net weight | L(mm) | W(mm) | H(mm) |

SDZF-1 | 1.2 | 25 | G1" | 1/2 | 745 | 1×50 | 220 | 400 | 1080 | 850 | 1460 |

SDZF-2 | 2.5 | 40 | G1" | 1/2 | 745 | 1×50 | 220 | 440 | 1100 | 900 | 2050 |

SDZF-3 | 3.6 | 60 | G1" | 3/4 | 1330 | 1×100 | 220 | 460 | 1200 | 1000 | 1808 |

SDZF-4.5 | 5 | 85 | G1 1/2" | 1 | 2670 | 1×135 | 220 | 660 | 1290 | 1030 | 2263 |

SDZF-6 | 6.8 | 105 | G1 1/2" | 1.5 | 4500 | 1×230 | 220 | 775 | 1500 | 1105 | 1931 |

SDZF-8 | 8.5 | 150 | G2" | 2 | 5340 | 2×135 | 220 | 970 | 1500 | 1240 | 2016 |

SDZF-10 | 10.9 | 185 | G2" | 2.5 | 5340 | 2×135 | 220 | 1120 | 1500 | 1240 | 2316 |

SDZF-12 | 12.8 | 185 | G2" | 2.5 | 5340 | 2×135 | 220 | 1120 | 1500 | 1240 | 2316 |

SDZF-15 | 16 | 310 | DN65 | 3 | 7600 | 2×190 | 380/220 | 1700 | 1960 | 1450 | 2342 |

SDZF-20 | 22 | 395 | DN65 | 4 | 7600 | 2×190 | 380/220 | 1800 | 1980 | 1600 | 2408 |

SDZF-25 | 26.8 | 492 | DN80 | 5 | 9000 | 2×230 | 380/220 | 2100 | 2270 | 1700 | 2460 |

SDZF-30 | 32 | 600 | DN80 | 6 | 9000 | 2×230 | 380/220 | 2300 | 2420 | 1780 | 2506 |

SDZF-40 | 43.5 | 725 | DN100 | 7 | 12500 | 2×420 | 380/220 | 2700 | 2100 | 2340 | 2673 |

SDZF-50 | 53 | 855 | DN100 | 10 | 13500 | 3×230 | 380/220 | 2900 | 2100 | 2390 | 2687 |

SDZF-60 | 67 | 1005 | DN125 | 12 | 18750 | 3×420 | 380/220 | 3350 | 2250 | 2600 | 2814 |

SDZF-80 | 90 | 1335 | DN125 | 13.3 | 25000 | 4×420 | 380/220 | 4200 | 2640 | 2600 | 2866 |

Explore More Products

Hot Searches