NaN / 0

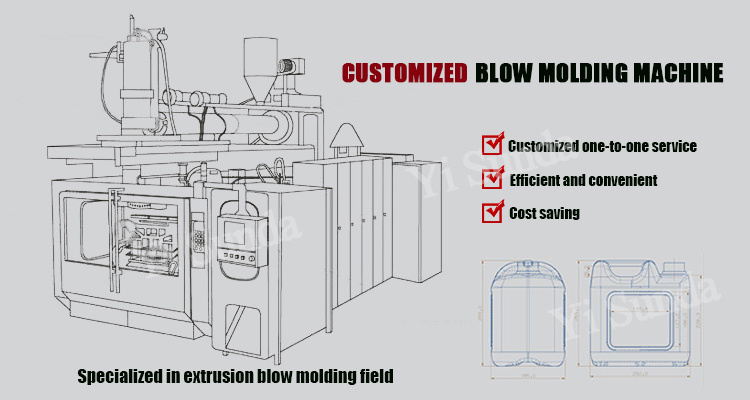

Full automatic hdpe pp extrusion blow molding machine jerry can blowing moulding machine

Get Latest Price

US$ 51000

≥1 Sets

Quick Details

Clamping Force (kN):

260

Output (kg/h):

120 kg/h

Place of Origin:

Hebei, China

Brand Name:

YI SUNDA

Product Details

|

the biggest litter

|

L

|

5L

|

|

Productive capacity

|

PCS/HR

|

180-2503

|

|

Clamping force

|

KN

|

260

|

|

platen opening stroke

|

MM

|

180-500

|

|

Mould thickness

|

MM

|

185-300

|

|

Heating zone Number

|

PART

|

10

|

|

move distance

|

MM

|

700

|

|

Screw diameter

|

MM

|

80

|

|

hydraulic servo motor power

|

KW

|

34

|

|

Screw L/D ratio

|

L/D

|

1:25

|

|

Plasticising Capacity

|

KG/HR

|

120

|

|

Voltage/Frequency

|

V/HZ

|

380V50HZ

|

|

Extrusion machinery motor power

|

KW

|

30

|

|

Total power

|

KW

|

68

|

|

The average energy consumption

|

KW

|

20

|

|

Compressde Air Required

|

MPA

|

0.6—0.8

|

|

Dimension

|

M

|

2.2(W)*4.4(L)*2.4(H)

|

|

weight

|

T

|

8

|

resistance, fast speed and so on.

the circuit when shooting troubles.

change, retrieval, monitoring, fault diagnosis and other functions can all be realized on the touch screen. Easy to operate.

We have exporte to all over the worlds. for example Australia, Indonesia,Singapore, Thailand, Cambodia, Vietnam, Bangladesh,India,Pakistan, Mexico, Peru,Chile, Brazil, Egypt, South Africa, Nigeria, Sierra Leone, Sudan, Mali, Kazakhstan,Kyrgyzstan,Turkey, Iraq,etc.

FAQ:

1. Can I make milk bottle on this machine

Yes, you can. Milk bottle, detergent bottle,pattern pot are available on the machine.

2. What shall I provide to you for offer?

Please send us your bottle picture with width,length,weights etc and better to send samples.

3. What kinds of materials the blow machine make?

The blow molding machine can make HDPE,PP material bottles.

4. What is your delivery time?

30 days to 50days.

5. How can I trust your machine ?

- We have more than 10 years experience have own design team and experience

engineer.

- You can visit us to check.

- We give professional guidance service during enquiry period.

- We provide after sale install service to abroad clients.

1. Can I make milk bottle on this machine

Yes, you can. Milk bottle, detergent bottle,pattern pot are available on the machine.

2. What shall I provide to you for offer?

Please send us your bottle picture with width,length,weights etc and better to send samples.

3. What kinds of materials the blow machine make?

The blow molding machine can make HDPE,PP material bottles.

4. What is your delivery time?

30 days to 50days.

5. How can I trust your machine ?

- We have more than 10 years experience have own design team and experience

engineer.

- You can visit us to check.

- We give professional guidance service during enquiry period.

- We provide after sale install service to abroad clients.

Hot Searches