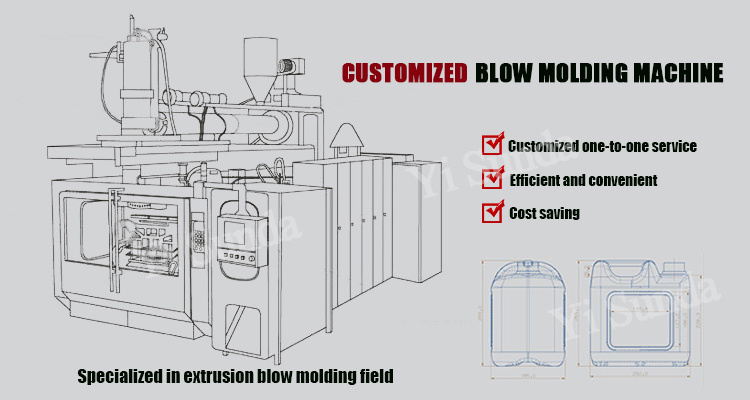

Our continous extrusion machine can adopt 1/2/3/4/6 head for wider product application range to fit bottles of different volume,

also match with related extrusion system it adopt view stripe head and multi-layer co-extrusion head to fit different functional

products.