NaN / 0

Wiped film short path molecular distill short path destillation shortly path distillation for oil

Get Latest Price

US$ 76179

≥1 Sets

US$ 71529

≥2 Sets

Quick Details

Place of Origin:

Shaanxi, China

Brand Name:

TOPTION

Voltage:

220V/50HZ, 380V

Power:

750W

Product Details

Product Description

Short path (molecular) distillation system

is considered as the safest mode of separation and to purify the thermally unstable molecules & related compounds with low volatility & elevated boiling point. In the high vacuum environment, molecular distillation has the advantages of low distillation temperature, short heating time and rapid separation.

|

|

MDS-20CE

|

MDS-30CE

|

MDS-50CE

|

|

Feeding Rates(L/h)

|

5L-25L/H

|

5L-30L/H

|

10L-50L/H

|

|

Throughput

(kg/h) |

5 – 25 kg/h

|

5 – 30 kg/h

|

10 – 50 kg/h

|

|

Evaporation Area (㎡)

|

0.2㎡

|

0.3㎡

|

0.5㎡

|

|

Diameter

|

7 inch

|

8 inch

|

12 inch

|

|

Scraper Motor Power (w)

|

370W

|

550W

|

750W

|

|

Speed Regulation Mode

|

Electronic speed regulation

|

Electronic speed regulation

|

Electronic speed regulation

|

|

Max.Scraping Speed (rmp)

|

200~1000rpm/min

|

450

|

Frequency control of motor speed

|

|

Heat Exchanging Area (㎡)

|

0.60

|

1.00

|

1.70

|

|

Volume(L)

|

20L

|

30L

|

50L

|

|

Jacket Volume(L)

|

14L

|

\

|

20L

|

|

Standard Feeding Rate (L/h)

|

5L~25L/H

|

5L~30L/H

|

10L~50L/H

|

|

Drive Motor Power (w)

|

200W

|

200W

|

1500W

|

|

Type

|

0.6㎡chiller cooling cold trap

|

1㎡chiller cooling cold trap

|

1㎡chiller cooling cold trap

|

|

Heavier component discharge

|

5L~15L/H

|

5L~30L/H

|

10L~50L/H

|

|

Type

|

3L liquid nitrogen cold trap

|

3L liquid nitrogen cold trap

|

5L liquid nitrogen cold trap

|

|

Lighter component discharge

|

5L~15L/H

|

5L~30L/H

|

10L~50L/H

|

Function

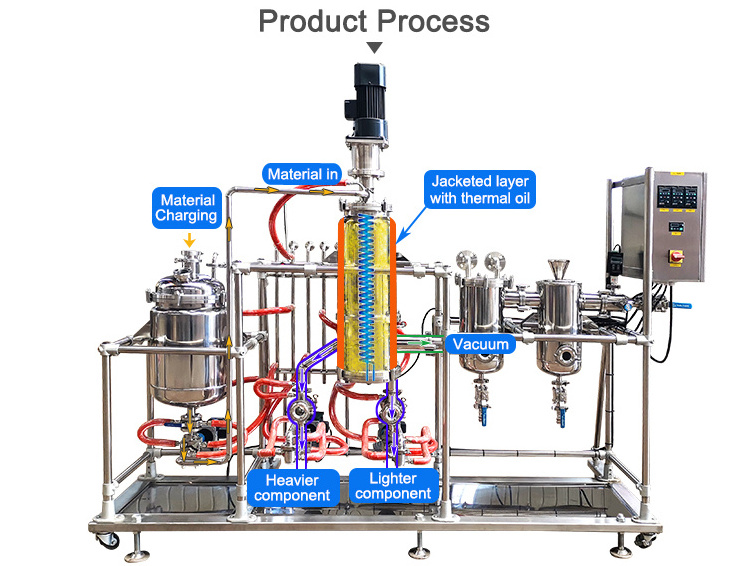

1. The control system of the vacuum unit reaches the required vacuum.

2. The temperature control unit control system reaches the required temperature.

3. Material feeds to the evaporation tower through gear pump.

4. The scraper in the evaporation tower rotates quickly to allow the material to form a thin film. The material liquid volatilizes under high vacuum and heating conditions. The molecular free path of light components is larger and is captured by the inner condenser, and the molecular free path of heavy components is smaller and falls back to the wall of the evaporation tower.

5. The light component flows down the inner condenser and is pumped out of the system by a gear pump or pumped to the next short-range. The heavy component flows down the wall of the evaporation tower and is pumped out of the system by a gear pump or pumped to the next short-range.

6. The ultralight components and residual solvents that have not been trapped by the inner condenser are trapped in the outer condenser and cold trap.

Feedback

Packing and shipping

Our company

Certificate and exhibition

Our Factory

Hot Searches