NaN / 0

50TPD /100TPD Complete Mineral Processing Equipment Fluorite Mining Plant

Get Latest Price

US$ 35000

≥1 Sets

US$ 12000

≥3 Sets

Quick Details

Production Capacity:

1-1000tons per hour

Place of Origin:

Jiangxi, China

Brand Name:

jxsc

Voltage:

can be customized

Product Details

Product Description

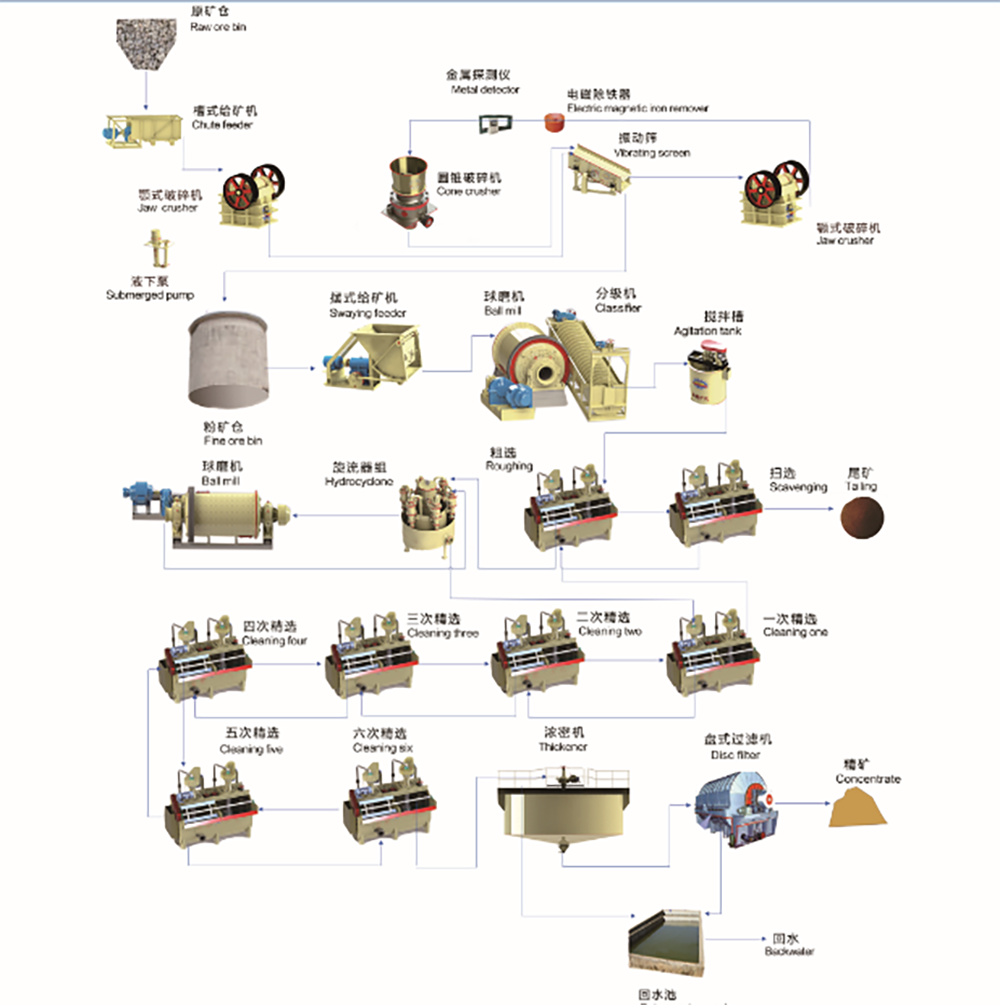

Fluorite Processing

The main component of fluorite is CaF2, which is often used as a source of fluorine in industry. Fluorite ore can be sorted by means of gravity separation and flotation. When the raw ore is coarse-grained fluorite ore, a gravity separation process can be used. The flotation process can be used when the raw ore has a high mud content, is accompanied by impurity minerals, or the useful minerals are inlaid with a fine particle size. Fluorite often coexists with minerals such as quartz, barite, calcite, and sulfide ores. According to different ore properties, the specific flotation process is also different.

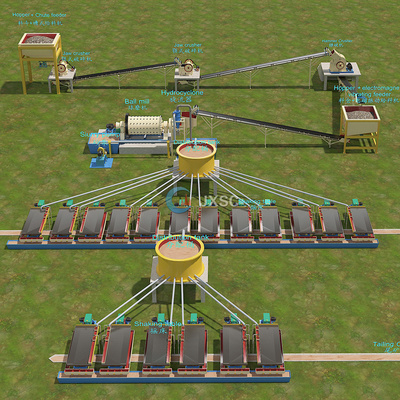

Fluorite gravity process

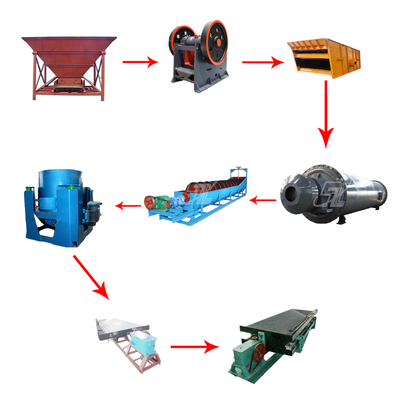

Crushing And Screening

Due to the different nature of fluorite mines in different regions, some processing plants use a three-stage one-closed crushing process, and some processing plants use a three-stage open-circuit crushing process. The fluorite ore beneficiation equipment in the crushing and screening stage is shown in the table below.

|

Equipment

|

Stage

|

Processing size (mm)

|

|

Jaw crusher

|

Coarse crushing

|

<1250

|

|

Standard cone crusher

|

Medium crushing

|

<350

|

|

Short head cone crusher

|

Fine crushing

|

<130

|

|

Vibrating screen

|

Screening

|

<30

|

Grinding

The two-stage grinding process is usually used in the grinding stage of fluorite mines. When fluorite and other minerals are closely coexisting in fine particles, the first stage grinding usually cannot well separate the monomers of fluorite and associated minerals, so After a period of grinding, coarse grinding of concentrates and re-grinding is a commonly used method in the separation of refractory fluorite ore, which is beneficial to the subsequent stage of separation and improves the selection index.

Gravity Separation

Scope of application: suitable for high-grade fluorite nuggets and particle mines with a particle size of 6-20mm.

Technological characteristics: The gravity beneficiation efficiency is remarkable, the equipment structure is simple, and the operation is convenient. The main fluorite mine beneficiation equipment is a jig, among which the diaphragm jig is commonly used. Diaphragm jigs produced by WALKER are divided into two types, left-handed machines and right-handed jigs. The upper limit is 6-8mm. It is not only widely used in fluorite ore beneficiation process, but also widely used in the separation of gold, tin, tungsten and other minerals.

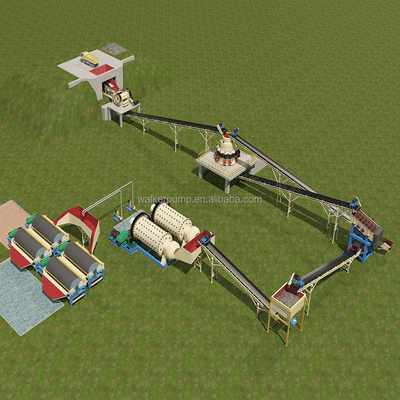

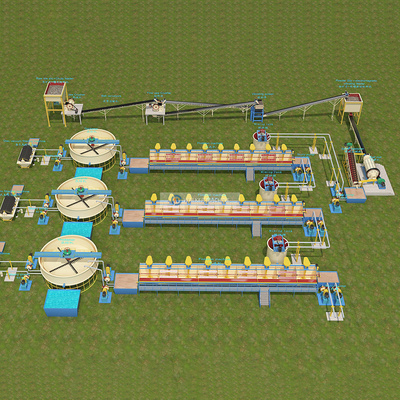

Fluorite flotation process

The beneficiation of fluorite ore is gravity separation and flotation process. The specificity of fluorite flotation: 1. Because industrial making hydrofluoric acid require calcium fluorite content>98% and silica <1%, fluorite flotation generally use 5-7 stages concentration; 2. When the PH of ore pulp is 8-11, the floatability is good. Another, increasing the temperature of ore pulp can improve flotation index.

Application

Fluorite flotation process is suitable for high silt content, impurities mineral and fluorite symbiose, fine disseminated grain-size, etc complex ore property and difficult separation fluorite ore.

Process introduction

1.

Separation of fluorite and sulphide ore:

generally, use xanthate collector to emerge sulphide ore, then add fatty acid collector to float fluorite. Another, during flotation processing, add little sulphite inhibitor to guarantee the quality of concentrated fluorite.

2.

Separation of fluorite and barite: Generally, use bulk flotation and then separate. During bulk flotation, use oleic acid as collector to get bulk concentrate. The separation of bulk concentrate can use direct flotation or reverse flotation to get concentrated fluorite.

3.

Separation of fluorite and quartz: Use fatty acid to collect fluorite and use water glass to restrain quartz. The dosage of water glass should be proper, little dosage have activation for fluorite ore, but is not enough to control quartz. Over dosage will control fluorite ore. Sometimes, to increase the inhibiting effect, it will add some polyvalent metal ion and it will also control calcite.

Main Products

We have professional engineers team to draw flowchart based on customer's stone site details.

We supplied full set

Quartz ore processing plant

:

Jaw crusher,

Ball mill, Spiral

classifier

, Flotation Machine,

Disc filter, Thickener, Agitation tank

.

Packing & Delivery

●Ways Of Packing

1.Small parts packed in the wooden cases.

2.Big parts packed by plastic membrane.

3.The whole big machine is loaded in the container.

● Shiping by sea/air freight

or any way the customer requires.

Company Introduction

Jiangxi walker Machinery Co.,Ltd, are a professional manufacturer of complete set mining equipments, a sub-company of JXSC mine machinery factory in Jiangxi province.professional at providing complete set processing equipments for Gold ore /Tin ore /Tungsten ore /Iron ore / Diamond/ Coltan ore / Silica sand / Zircon sand/ Black sand/Chrome ore, ect. As well as complete set small lab mining machines.

Our core advantages as below:

1.+30years history factory at mining machinery

2.Provide engineer team after sale service

3.Provide complete set mineral processing plant

4.Provide sample testing service in factory lab for free

5.Provide professional ming soolution consulting

1.+30years history factory at mining machinery

2.Provide engineer team after sale service

3.Provide complete set mineral processing plant

4.Provide sample testing service in factory lab for free

5.Provide professional ming soolution consulting

|

1.Inquiry and consulting support.

2.Ore sample testing support. 3.View our Factory. 4.Design Flowchart. |

1.Training how to instal the machine, training how to use the machine.

2. 1 year warranty . 3.Engineers available to service machinery overseas. |

FAQ

●

Pre-sales service:

We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

● Sales service: Send technicians to the site to guide the installation and commissioning, train the operators, and complete the acceptance with you.

● After-sales service: To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

● Lifelong service: One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

● How is the quality of your products?

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

● How about the Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we

described or the promise before you place order, we promise 100% refund.

●How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

● How about the service and payment terms?

Answer: We can accept T/T or other payment ways you request; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

● Sales service: Send technicians to the site to guide the installation and commissioning, train the operators, and complete the acceptance with you.

● After-sales service: To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

● Lifelong service: One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

● How is the quality of your products?

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

● How about the Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we

described or the promise before you place order, we promise 100% refund.

●How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

● How about the service and payment terms?

Answer: We can accept T/T or other payment ways you request; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

Hot Searches