NaN / 0

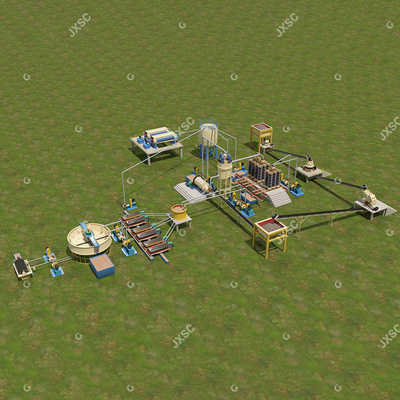

100tpd Mining Separation Concentrate Equipment Mineral Processing Copper Ore Beneficiation Plant

Get Latest Price

US$ 30000

≥1 Sets

US$ 10000

≥3 Sets

Quick Details

Production Capacity:

1-500tph

Place of Origin:

Jiangxi, China

Brand Name:

JXSC

Voltage:

380V or customized

Product Details

Product Description

Overview

▼

The main beneficiation method of copper ores is flotation, in some cases the gravity separation and magnetic separation are applied. Generally, copper sulfide ore, mixed copper ore and copper oxide ore are processed by flotation method. For the refractory mixed copper ore and refractory copper oxide ore, hydrometallurgy or combined hydrometallurgy and flotation are adopted.

Application

▼

Copper ore processing can be applied to all kinds of copper sulide ores, as well as most mixed copper ores and copper oxide ores. It has significant separation effect for chalcopyrite, copper molybdenum ores and porphyry copper ores.

Features

▼

1.The principle of more crushing and less grinding is achieved. The ore particle size is crushed to 10-12mm or less by

three-stage-crushing with single closed circuit stage process to reduce the load of the grinding system.

three-stage-crushing with single closed circuit stage process to reduce the load of the grinding system.

2.Use New flotation reagents The fiotation results can be greatly improved by using compound collectors instead of traditional xanthate collector.

3.Pneumatic flotation machine is used to ensure the flotation effect Pneumatic fiotation machine is adopted to obtain good ore beneficiation indicators.

3.Pneumatic flotation machine is used to ensure the flotation effect Pneumatic fiotation machine is adopted to obtain good ore beneficiation indicators.

4.High degree of automation Through the automatic control system, the whole process of ore beneficiation

is under monitoring, so the production line can be large -scale, automatic and easy to manage and control.

is under monitoring, so the production line can be large -scale, automatic and easy to manage and control.

Successful Cases

Zambia 10TPH Rock Copper Ore Processing Plant

This JXSC Processing plant Setup is Rock Copper Gravity Separation Plant. Complete set include Feeding Hopper, Chute Feeder, Rough Jaw crusher, Fine Jaw crusher, Hammer crusher, belt conveyor, Copper Concentration Shaking table,ect. This designed flowchart is suitable to process Oxide type and Sulfide type copper, and man other minerals , such as rock gold, rock Chrome ore , rock coltan ore, rock tin ore, rock Mn ore, rock zinc lead, ect. The flowchart can be designed according to customer’s minerals real conditions and requirements for plant.

This JXSC Processing plant Setup is Rock Copper Gravity Separation Plant. Complete set include Feeding Hopper, Chute Feeder, Rough Jaw crusher, Fine Jaw crusher, Hammer crusher, belt conveyor, Copper Concentration Shaking table,ect. This designed flowchart is suitable to process Oxide type and Sulfide type copper, and man other minerals , such as rock gold, rock Chrome ore , rock coltan ore, rock tin ore, rock Mn ore, rock zinc lead, ect. The flowchart can be designed according to customer’s minerals real conditions and requirements for plant.

Rock Copper Processing plant

This JXSC Setup is complete set Rock Copper Processing plant, including crushing, grinding, gravity separation, copper concentrate ore dewatering system, tailing water recycle system,ect. Main machines include feeding hopper, chute feeder, primary jaw crusher, secondary jaw crusher, impact fine crusher, ball mill, spiral chute, shaking table, cone thickener for concentrate, plate filter press, thickener for tailings. This designed plant is high recovery ratio and effect for recovery Oxide type rock copper and many other type minerals, such as rock chrome ore, rock Mn ore, Rock Zinc Lead,ect. The plant design can be adjustable according to material conditions and requirements.

This JXSC Setup is complete set Rock Copper Processing plant, including crushing, grinding, gravity separation, copper concentrate ore dewatering system, tailing water recycle system,ect. Main machines include feeding hopper, chute feeder, primary jaw crusher, secondary jaw crusher, impact fine crusher, ball mill, spiral chute, shaking table, cone thickener for concentrate, plate filter press, thickener for tailings. This designed plant is high recovery ratio and effect for recovery Oxide type rock copper and many other type minerals, such as rock chrome ore, rock Mn ore, Rock Zinc Lead,ect. The plant design can be adjustable according to material conditions and requirements.

Packing and Delivery

◆ Ways of packing

1. Small parts packed in the wooden cases

2. Big parts packed by plastic membrane

3. The whole big machine is loaded in the container

◆ Shiping by sea/air freight

any way the customer requires.

Hot Searches