NaN / 0

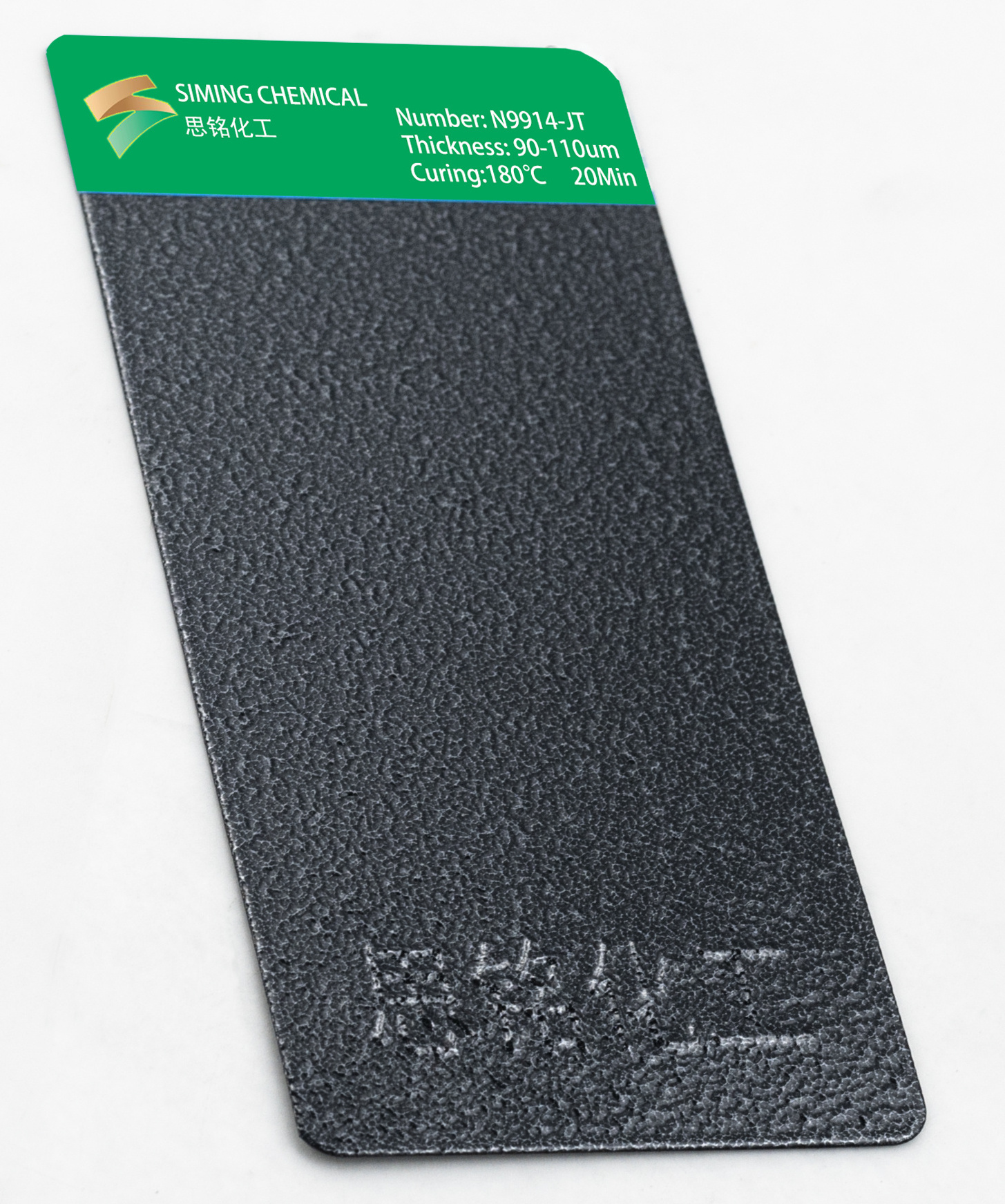

Popular Design Candy Color Chair Chrome Electrostatic Epoxy spray Coating paint Alloy Wheel Coating Powder

Get Latest Price

US$ 4

≥500 Kilograms

US$ 3.8

≥1000 Kilograms

US$ 3.5

≥15000 Kilograms

Quick Details

CAS No.:

Complex chemical

Other Names:

powder paint

MF:

N.A

EINECS No.:

N.A

Product Details

Popular Design Candy Color Chair Chrome Electrostatic Epoxy Coatingpaint Alloy Wheel Coating Powder

Product Description

Specification

|

Thermosetting Epoxy (also called E typle) powders include a series of products such as standard curing, rapid curing and Low-temperature curing powders with high gloss, semi-gloss and matt finishes. These products may provide coatings with excellent adhesion,hardness,chemical resistance, physical and mechnical properties. They are suitable for surface coatings of kitchen utensils, cases of insturmnets and apparatus, display racks, mechanical and electrical equipments, auto parts, copper and aluminium articles etc.

|

|

|

||

|

Key Technical Indexes of Powder:

|

Thermosetting Epoxy Powders

|

|

||

|

Item

|

Index

|

Note

|

||

|

Appearance (visual)

|

Homogenous colour without any agglomerate

|

|

||

|

Gel time

|

200°C ±2°C 30-180S

|

|

||

|

Fineness (180 mesh sieve residue)

|

< 0.5%

|

or per custom's request

|

||

|

Fused flowability

|

150°C ± 2°C 20-55mm

|

or per custom's request

|

||

|

Curing conditions

|

180°C ± 2°C 15-20mm

|

Effective temperature

|

||

|

Properties of Coating Film

|

|

|

||

|

Item

|

Index

|

|

||

|

Color

|

In accordance with standard colour panels or within range,negotiated by custom and supplier

|

|

||

|

Appearance of film(visual)

|

Smooth, Slightly orange peeled

|

|

||

|

Gloss(60 gauge head)

|

high gloss:>=85%, semi-gloss:51-84%, Low gloss:15-50%, matt:<14%

|

|

||

|

Cured film thickness

|

60-80 um

|

|

||

|

Impact resistance(drop hammer)

|

50kg.cm(4.9Nm)pass(direct)

|

|

||

|

pencil hardness

|

2H without scratch

|

|

||

|

Adhesion(cross cut test)

|

1mm 6X6 0 grade

|

|

||

|

Bending test(tapering spindle)

|

3mm pass

|

|

||

|

Cupping test

|

> 6mm

|

|

||

|

Dent hardness

|

4Kg (39N) pass

|

|

||

|

Salt spray test

|

500h

|

|

||

|

Humid heat resistance

|

500h

|

|

||

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Explore More Products

Hot Searches