NaN / 0

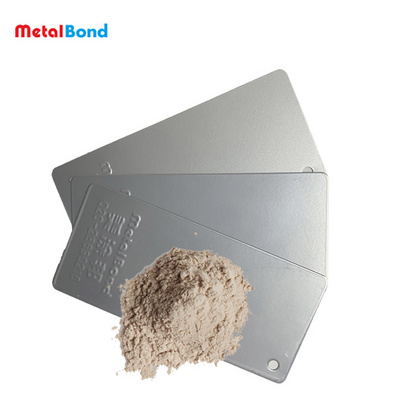

color chrome spray paint mirror effect powder coating chrome powder coating

Get Latest Price

US$ 5.56

≥20 Kilograms

US$ 5.38

≥2000 Kilograms

Quick Details

CAS No.:

N/A

Other Names:

Metal Powder series powder coating

MF:

N/A

EINECS No.:

N/A

Product Details

color chrome spray paint mirror effect powder coating chrome powder coating

Product Description

Parameter details

color chrome spray paint mirror effect powder coating chrome powder coating

| Product Details | |

| Main Material | Epoxy, Epoxy Polyester, Pure Polyester, Acrylic, Polyurethane, etc. |

| Gloss | High Light, Flat Light, Matte, No Light |

| Texture |

Sand, Wrinkles, Transparent, Hammer, Turtle, Cracks, Point Spread, Metal Effect,

Antique, etc. |

| All the conditions of the gloss, texture, color, etc. of the powder can be customized. | |

| Application Conditions | |

| Applicable Equipment |

High voltage electrostatic spraying, Friction electrification, Electrostatic fluidized bed, Corona electrostatic coating,etc. Depending on the situation |

| Coating Thickness | Used between 40-150 μm |

| Average Coverage | 10-12 m² / kg, coating thickness 60 μm (100% utilization) |

| Curing Condition | Standard type 180°C for 15 minutes |

| Physical Properties | |

| Specific Gravity | 1.4~1.8g/cm³, Depending on recipe and color |

| Particle Size | Standard type average particle size 35-40 μm |

| Coating Properties | |

| Mechanical Properties | Pencil hardness GB/T 6739-1996 H-2H |

| Adhesion (cross-cut method) GB/T 9286-1998 Grade 0 | |

| Bending test GB/T 6742-1986 ≤ 2mm | |

| Impact test GB/T 1732-1993 ≥50kg.cm | |

| Cupping test GB/T 9753-1988 ≥7mm | |

| Corrosion Resistance | Salt spray test GB/T 1771- 1991 >500 hours, no change, crossion width at crossing ≤ 2mm |

| Damp heat test GB/T 1740-1979 >1000 hours, mild loss of gloss | |

| Temperature resistance 100°C/48 hours, excellent gloss retention | |

| Storage Conditions | |

| In dry, ventilated indoor storage, avoid direct sunlight, up to 12 months. | |

Main categories

Product Application

Production Process

Packaging & Shipping

All products are packed with standard plastic bags and carton.

Net weight 20kg or 25kg , and ensure no-leaking.

For destination of harsh climate,

we will do a good job holding shipments, avoid product deterioration.

Explore More Products

Hot Searches