NaN / 0

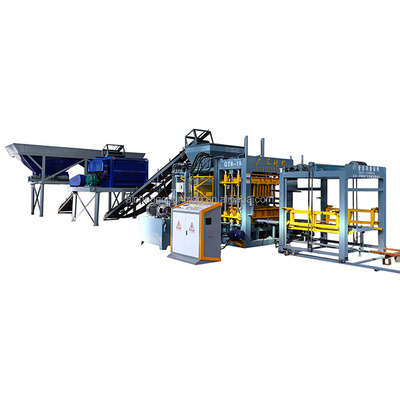

bloquera automatic qt8-15 automatic hollow concrete block making machine

Get Latest Price

US$ 70000

≥1 Sets

US$ 63000

≥2 Sets

Quick Details

Type:

paver brick, solid brick

Brick Raw Material:

Cement,sand,aggregate,clay,fly ash,construction rubbish

Production Capacity (Pieces/8 hours):

1440-1920pcs/hour

Brick size:

200*100*60 mm, 240*115*90 mm, Other

Product Details

Product Description

automatic hydraulic fly ash brick making machine/paver block making machine price/concrete block making machine manufacturers

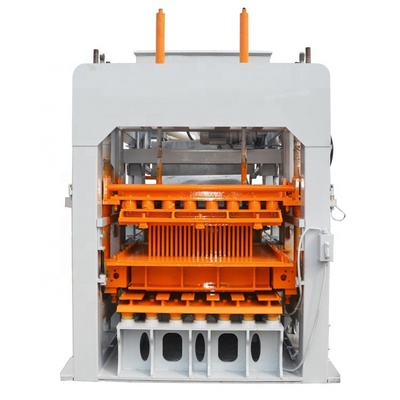

AS the molds are changeable, this concrete brick machine is able to produce different types of blocks/bricks, and this is a

hydraulic machine can produces a stronger block, due to the greater pound pressure applied by the hydraulic system.

The block manufacturer can also realize substantial savings by using less cement. A ratio from 8:1 to 11:1 sand/cement can be achieved. This machine is designed for the manufacturer with a steady year turnover and with a certain number cash to make the

factory running.

factory running.

|

host machine size

|

3800*2200*2750mm

|

|

block making period

|

15-20s

|

|

vibrating force

|

70-100kn

|

|

host machine power

|

45kw

|

|

host machine weight

|

10.5t

|

|

pallet size

|

1050*900*28mm

|

|

Brick types can make

|

all kinds of types, only need to change the molds.

|

|

vibrating frequency

|

2800-4500

|

-

automatic hydraulic fly ash brick making machine/paver block making machine price/concrete block making machine manufacturers

-

-

This machines can be equipped with an automatic elevator/skip for loading mix into hopper,

agitator, an automatic pallet feeder, pallet ejector, brush for cleaning blocks and a run off conveyor

1, Electrical system adopts imported color touch screen and programmable controller PLC control equipped with data input/output

device, control system including the safety logic control and fault diagnosis system.

2, imported hydraulic components and seal, high dynamic performance proportional valve, according to different work required

control oil quantity and pressure, to the essence key components that control the action.

3, the machine adopts high precision, high strength castings and special welding technology and materials manufacturing, good

rigidity, shock resistant, long service life.

-

Theoretical Production Capacity

|

Name

|

block size

|

block making period

|

blocks per mold

|

Production capacity

|

|

Hollow block

|

400x200x200

|

15-20s

|

8

|

1440-1920pcs/hour

|

|

Multi-hole brick

|

240x115x90

|

15-20s

|

21

|

3780-5040pcs/hour

|

|

Solid brick

|

240x115x53

|

15-20s

|

45

|

8100-10800pcs/hour

|

|

paver

|

200x100x60

|

20s

|

28

|

5040pcs/hour

|

|

Ishape paver

|

200x163x60

|

20s

|

20

|

3600pcs/hour

|

production process

automatic hydraulic fly ash brick making machine/paver block making machine price/concrete block making machine manufacturers Advantage:

- Use Germany Siemens PLC control system and Siemens Touch Screen, use Schneider and Omron relays and contactors:

- Siemens PLC, with great adaptability, guarantees the stability and reliability of the machine.

- Visualization touch screen, with easy operation;

- High-quality electrical components from Schneider and Omron;

- Use Frequency Conversional Control Technology, which controls the block making:

- Frequency Conversion Control: guarantees the precise and parallel movement between tamper head and mould, protects the products from transfiguration; increases the production rate by improving the vibrating efficiency;

- Controls the instantaneous start and stop of the motors, to protect the motor from over-heating caused by constant working;

- Power saving: 30%;

- Use Double high-dynamic Proportional/Directional Valves to automatically adjust the oil flow and pressure

- Buffer the hydraulic cylinder, to protect the cylinder from damage caused by inertia;

- Guarantee production stability;

- 360° Multi-Shaft Rotating and Compulsory Feeding:

- Speedy and rotating feeding, with uniform mixing, to make sure that the density and intensity of the products are guaranteed

- This uniform feeding is applicable for different kinds of raw materials and moulds;

- Use heat treatment on moulds and main parts of the machines:

- Heavy duty machine structure and wear resistant moulds;

- The hardness reaches up to HRC 52-58;

- Greatly improves the using lifetime of the machine by 50%

- Other resons help you to make choice:

- A.It reduces the starting current of the motor with a function of soft starting.

-

B.It realizes the synchronized operation of vibration assembly.

C.Braking unit and braking resistor are used to consume the energy to

solve the problem of inertia of the motor upon braking.

D.High-effective parts of hydraulic proportion system are imported

(more effective and more energy consecutive).

E.Arch-breaking rapid-feeding device (has a great advantage for feeding for porous bricks.

It makes feeding much evener.)

F.Variable-frequency motor and multi-source synchronous vibration system are used.

G.Vibration and forming

Detailed Images

automatic hydraulic fly ash brick making machine/paver block making machine price/concrete block making machine manufacturers

Gemany Technology, China Produce

Material for making blocks

automatic hydraulic fly ash brick making machine/paver block making machine price/concrete block making machine manufacturers

This is the most popular proportion in making block making machine:

1. S tandard concrete block : Cement 9-12% , sand 40% , stone 45%, water 3%

2. L ight concrete block : Cement 9-12% , slag 80-90%, water 3%

3. Cement 9-12% , sand 10-20% , stone 30-40% , slag 25-50%, water 3%

4. C ement 8%-10%, sand 30%-40%, stone 50%-60%

5. C ement 8%, sand 60%, Fly ash 30%, gypsum 2%.

Packing&Shipping

automatic hydraulic fly ash brick making machine/paver block making machine price/concrete block making machine manufacturers

Whole life service:

Pre-Sale

1.Perfect 7*24 hours inquiry and professional consulting services.

2.Visit our factory anytime.

In-Sale

1.Update the production schedule in time.

2.Quality supervision.

3.Production acceptance.

4.Shipping on time.

After-Sales

1.Warranty period :1 year after acceptance, during this period we will offer free spare parts if they are broken.

2.Training how to install and use machine.

3.Engineers available to service overseas.

4.Skills support the whole using life.

Factory

Contact Me

Hot Searches