NaN / 0

QT15-15 Full Automatic Hollow Block Making Machine Machine Brique Maquina Bloquera

Get Latest Price

US$ 72000

≥1 Sets

Quick Details

Type:

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

Brick Raw Material:

Cement

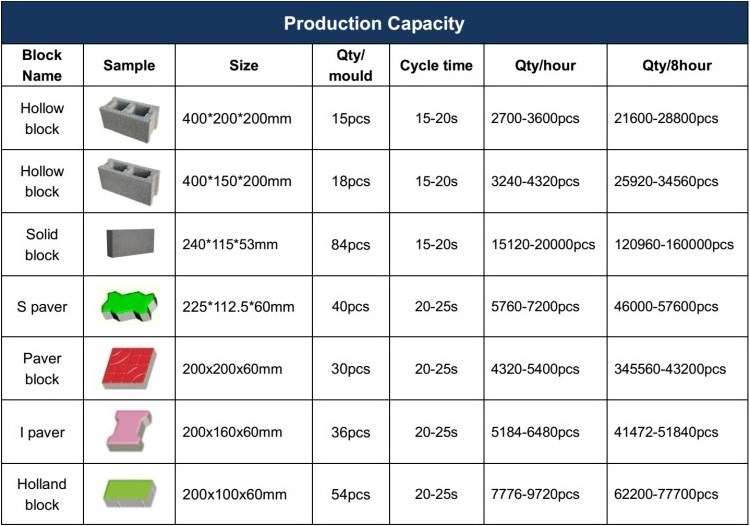

Production Capacity (Pieces/8 hours):

21600-28800pcs/ 8hours

Brick size:

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

Product Details

Product Description

Introduction:

1. Particular storage and description material system insure the feeding accuracy and avoiding the effect of exterior material. So the products have high density.

2. Adopting synchronization vibration insures the products making average. The frequency can change according to different technics. Low frequency in feeding material, high frequency vibration makes the different material to have a optimal vibration way.

3. The computer is of fault diagnosis system. Warning signal is propitious to eliminate the fault. Combine with long-distance controlling system, it can achieve scrutiny, controlling, diagnosis

4. PLC intelligent control: Man-machine interface, control system equipped with complete logic control, production program, malfunction diagnosis system and remote control function. So it doesn’t need a professional person but only need a simple training to the operator.

* SIEMENS Brand PLC Control Unit. (with Remote Control)

* Japan Yuken Brand Hydraulic Station

* SIEMENS brand motors

* Large Vibration box & 4 Vibration Motors.

* OMRON Switch

|

Technical Parameter |

|

|

Pallet size |

1300x1100mm |

|

Molding Cycle |

15-25s |

|

Host block machine power |

90Kw |

|

Block height |

50-350mm |

|

Exciting force |

148KN |

|

Dimension |

5100*2150*3390mm |

|

Weight |

12Ton |

|

Raw Materials |

crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. |

Whole line

Machine details

Machine advantage

Block sample

Customer Show

We have exported many block machines to more than 116 countries, such as: U.S.A, Mexico, Canada, Portugal, Australia, Russia, Armenia, Belize, Jamaica, Ecuador, Chile, Peru, Bolivia, Palestine, Pakistan, Philippines, Bangladesh, India, Syria, Saudi Arabia, Yemen, Oman, Egypt, Algeria, Ethiopia, Uganda, Tanzania, Mozambique, Zimbabwe, South Africa, Congo, Ghana, Nigeria, Senegal and so on.

If you want to see our machine working in locally, Please don't hesitate to contact me.

Whatsapp/ Mop: 0086-13220886224

Website: www.hfblockmachine.com

Hot Searches