NaN / 0

SMC fiberglass compression auto car bumper mould professional manufacturing automobile car parts molds

Get Latest Price

US$ 20000

≥1 Sets

US$ 15000

≥100 Sets

US$ 10000

≥200 Sets

US$ 6000

≥400 Sets

Quick Details

Shaping Mode:

Compression Mould

Place of Origin:

Zhejiang, China

Brand Name:

DEYING MOULD

Model Number:

DY202112140812

Product Details

SMC fiberglass compression auto car bumper mould professional manufacturing automobile car parts molds

DEYING is a professional manufacturer of automobile molds and has rich experience in automobile bumper mold manufacturing. The bumper mold designed by DEYING not only has the ability to reduce the injury of drivers and passengers during high-speed impact, but also has the ability to protect pedestrians. Sinofractal structure design is adopted in bumper mould. Compared with the traditional outer fractal structure design, the inner fractal design has higher requirements on the strength of the mold. Correspondingly, the design concept of the bumper mold made by the internal fractal structure is more advanced. Mould Name: Automobile Bumper Mould Product description: Auto Bumper Mould Mould cavity: 1 cavity The main material of the mold: cavity DIN1.2738; core DIN 1.2312 Mold injection system: hot runner injection Mould ejection system: cylinder ejection Mold cycle time: 50 S Delivery time: 100 working days

Product Description

1. Plastic injection car auto bumper Mold

2. Model: All

3. Size: Depend on Sample/3D Design drawing

4. Product Material: PP,ABS,PE ect.

5.Available for Customized

|

Product Name

|

SMC fiberglass compression auto car bumper mould professional manufacturing automobile car parts molds

|

|

Mould Cavity

|

1*1 cavity

|

|

Mould Steel

|

S50C/P20H/718/H13/S136/2316/2738etc

|

|

Steel Hardness

|

28-50HRC

|

|

Mould Base

|

LKM,DME,HASCO,self-made etc.

|

|

Mould Runner

|

Hot/Cold Runner

|

|

Hot Runner Type

|

China Hot Runner,YUDO, Husky, Synventive,Thermoplay,Ewikon, Mold Master,DME

|

|

Gate

|

Point Gate, Side Gate, direct gate way,Sub-Gate,Tab Gate, Fan Gate

|

|

Ejection

|

Stripper Plate, Ejection Block, Ejectors Pins,gas,Cylinder

|

|

Mould Life

|

》300,000 Shots ,Different steel with different mold life

|

|

Production Time

|

30-50days ,it depend on product

|

|

Mould Parts

|

China standard / SKD

|

|

Mould Quality Levels

|

Level A

quality(Highest Level Quality),

Level B

quality(Middle Level Quality),

Level C

quality(Lowest Level Quality) , different level with different price

|

|

|

When you send us the mould inquiry, please offer the following information:

1) Quality level you choose: Level A/Level B/Level C 2) Photo together with dimension/ drawing design |

|

|

For the Q/C of mould, there are 3 steps:

1.Mould Material Q/C - Mould Steel Checking,Standard Spare Parts Checking 2. Mould Making Process Q/C - Design checking ,Each part of mould's size checking after machining according to 2D drawing , Mould testing 3.Check with customer's requirement again before mould shipping. |

|

The Main Mould Steel and Hardness for you reference

|

|

|

|

|

|

|

|

|||||||

|

Steel Grade

|

S50C

|

P20

|

P20HH

|

718H

|

2738h

|

H13

|

S136

|

|||||||

|

Hardness(HRC)

|

17-22

|

27-30

|

33-37

|

33-38

|

36-40

|

48-52

|

48-52

|

|||||||

|

Mould Processing Detail Time Schedule

|

|

|

|

|

|

|

||||||

|

Prepare Mold Steel

|

CNC Machining

|

Precision CNC Machining

|

Drill

|

Polishing/Carving

|

Assembling and Fitting

|

T1 Mould Test

|

||||||

|

5 days

|

10 days

|

5 days

|

5 days

|

3-5 days

|

5 days

|

2 days

|

||||||

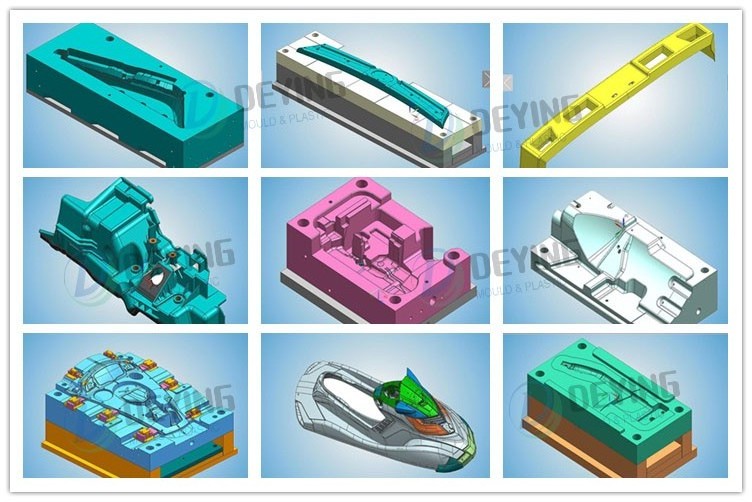

Product Show

Related Product Show

Main Product Show

Our Service

Our Company

Taizhou Huangyan Deying Mould Co.,Ltd., is a professional production of plastic injection mould,fiber glass(SMC/BMC) compression mould more than 10 years experience. We're specilized in mold ,plastic injection bumper mold ,SMC fiberglass compression auto car bumper mould professional manufacturing automobile car parts molds

Packing & Delivery

Packing Details : Mould packaged by wooden case

Delivery Details : In general mold shippment by sea,but small mould also can be by air based on client request.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 30-50 after client payment deposit and also confirm drawing. Different mold with different delivery time.

Q: Can you help us with the design?

A: YES,We'll be free to help with you design based on your 3D/Sample .

Q: Do you provide samples ? is it free or extra ?

YES,we will be send free sample for you confirm after we finished mold and test it .

Q: What is your terms of payment ?

A: T/T(50% T/T first payment + 50% T/T at samples confirmation , before shipment.).

If you have another question, pls feel free to contact us as below:

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 30-50 after client payment deposit and also confirm drawing. Different mold with different delivery time.

Q: Can you help us with the design?

A: YES,We'll be free to help with you design based on your 3D/Sample .

Q: Do you provide samples ? is it free or extra ?

YES,we will be send free sample for you confirm after we finished mold and test it .

Q: What is your terms of payment ?

A: T/T(50% T/T first payment + 50% T/T at samples confirmation , before shipment.).

If you have another question, pls feel free to contact us as below:

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com