NaN / 0

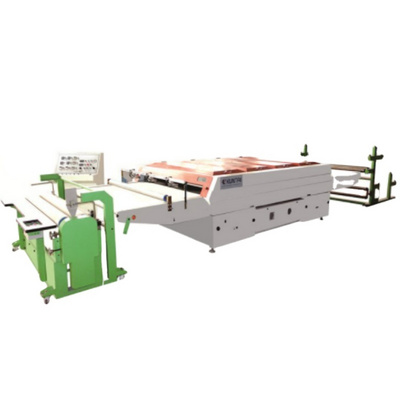

hot melt pur glue laminate machine wood panel roller glue coating and laminating line for acrylic/PET /PVC/ metal/HPL

Get Latest Price

US$ 36000

≥1 Sets

US$ 35000

≥5 Sets

Quick Details

Place of Origin:

Shandong, China

Brand Name:

ZHONGHAOCHENG

Weight (KG):

4000 KG

Power (kW):

75KW

Product Details

Product Description of

high gloss PET/PETG/PVC/ arcylic laminating machine

PET laminaing machine

honeycomb pvc panel laminating machine

High speed kitchen door/honey comb/WPC hollow door semi automatic PUR hot melt glue laminating machine

mdf acrylic lamination machine

MDF paper sticking machine high gloss pur hot melt glue roller lamination line

mdf flat panel laminating machine

film laminating machine pvc wall panel

flat panel mdf press lamination machine production line

This production line adopt the special precise hotmelt glue system .This machine is specialize in sticking on panel and multiplayer board, it is suitable for produce high-glossy , panel ,cabinet ,furniture door, honeycomb board and foam board sticking .etc .

1.Laminate material :High-gloss pvc , acrylic , HPL, PVC board and metal board ,PE, PET ,PVC, veneer , paper .ect.

2.Based panel material :MDF board ,chipboard, plywood, gypsum board, HPL, foam board ,aluminum panel ,steel panel.

3.Glue: PUR hotmelt glue .

4.User :Furniture ,cabinet ,panel door producer ,new building material factory ,high-grade decoration board factory .

Technical parameters of high gloss pvc film laminating machine

| Panel preheating | One heating channel(2 meters) |

| PUR glue machine | 55 gallans |

| silica gel glue coating roller | Φ240*1pc |

| steel glue roller | Φ190*1pc |

| Total glue spread roller | 4 rollers |

| steel glue roller heating | adopt a 15 kw oil heating machine |

| Glue heating after coating | one(2meters) |

| Air shaft for film | Two |

| Loading height of the hoist | 1.5Ton |

| silica gel pressing roller | Φ 24 0mm*1 pc |

| Hot steel pressing roller | Φ 24 0mm*1 pc |

| D rive motor Power | 9KW |

| PUR glue melt machine power | 20KW |

| Heating power | 24KW |

| Dust clean power | 1.1KW |

| Lifting table power | 6KW |

| Total power | 75.1 kw |

| Max.glue coating width | 1300mm |

| Max.working width | 1300mm |

| Processing thickness | 3 - 10 0mm |

| frequency converter | HZ |

| Motor | SIEMENS Motor |

| Electric parts | CHINT +Schneider |

| Max working speed | 2 - 1 8m/min |

| Voltage | 380V/50Hz |

Detail information of the PVC film laminating machine

1.Work table with conveyor rollers.

2. Dust removing is for remove dust and small article on the board surface before glue coating.

3. Panel preheating oven that for heating the panel before gluing, cause as the gluing using PUR hot melt. It can prolong the working time gluing adhesive.

4. Single side glue spreading, the glue coater roller is oil heating which precise heating element which create a stable and equality temperature, combine with melting tank that machine are more capability.

5. Working table for out feed conveyor roller.

6.This machine for panel size 1220*2440mm,we can also make the machine suitable for 1830*3660mm panel which need addition charge.

PUR glue tank adopts with 55 gallon tank and adopts with two heating pip which suitfor width roller coater and for thick glue coating requirement.

The PUR glue coater has twp types one with three rollers glue coater(one steel scraping roller one rubber glue coater, one rubber conveying roller) and the other is five rollers glue coating structure( one steel scraping roller one rubber glue coater,one ceramic roller and two rubber conveying roller)

the automatic machine line with auto panle laod and unload

Packaging & Shipping

The common package with PE film and it is safe enough for the shipment. but if necessary we can make the plywood package with extry charge

Hot Searches