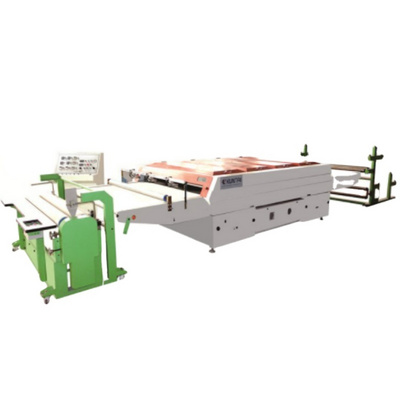

Application: the product is mainly used in garment fabrics, automobile interior decoration and other composite industries: This product can composite various thin and thick materials, such as spring Oxford cloth, Nisi spinning, fleece, knitted cloth, corduroy, TPU, PTFE. PE film and elastic cloth, Lycra, mesh cloth, all cotton sweat cloth, knitted cloth, non-woven cloth, towel cloth and so on.