NaN / 0

Lithium Battery Recycling Processing Equipment Solar Panel Lithium Battery Recycling Machine For Cathode Powder

Get Latest Price

US$ 50000

≥1 Sets

US$ 40000

≥2 Sets

US$ 30000

≥3 Sets

Quick Details

Production Capacity:

200-2000kg/h

Place of Origin:

Henan, China

Brand Name:

ENV-Guard

Power:

125

Product Details

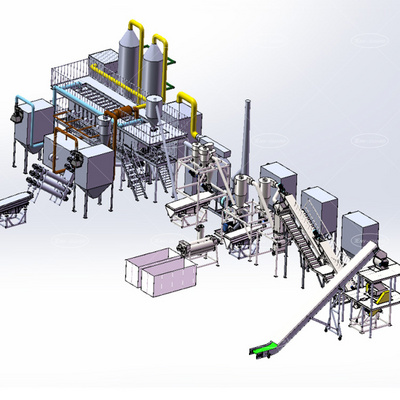

Lithium Ion Battery Recycling Plant

The waste lithium battery contains various rare raw materials such as copper, aluminum, graphite powder and lithium powder, and has high recycling value.

Copper in the negative electrode of waste lithium battery (content up to 35%) is an important production raw material widely used.Carbon powder adhered to it can be used as additives such as plastics and rubber. Based on the structural characteristics of lithium batteries,our company adopts an environmentally-friendly physical separation process to realize efficient separation and recovery of waste lithium batteries.

Copper in the negative electrode of waste lithium battery (content up to 35%) is an important production raw material widely used.Carbon powder adhered to it can be used as additives such as plastics and rubber. Based on the structural characteristics of lithium batteries,our company adopts an environmentally-friendly physical separation process to realize efficient separation and recovery of waste lithium batteries.

RAW MATERIALS

Soft lithium battery

Hard-shell lithium battery

Cylindrical lithium battery

Positive and negative plates

The lithium battery recycling production line is used for dismantling and recycling the Soft pack-age battery, cellphone battery,Shell battery,Cylindrical battery etc.

Different types of lithium batteries have different recycling procedures. Please contact us for detailed configuration.

Different types of lithium batteries have different recycling procedures. Please contact us for detailed configuration.

PRODUCTS DESCRIPTION

The pretreatment process of waste lithium ion batteries mainly comprises the following steps:after discharging the recovered waste

batteries, crushing, magnetic separation, air separation,crushing, gravity separation, screening and other processes are carried

out by mechanical equipment,so that the powder on the positive and negative pole pieces is effectively separated from the copper

aluminum foil, and the batteries are treated as valuable materials.

FINAL PRODUCTS

Copper

Aluminum

Shell

Diaphragm

Lithium Cobaltate

Graphite

TECHNOLOGICAL PROCESS

Shredder

:

Shredded lithium batteries into smaller pieces.Hammer crusher: For the secondary crushing of shredded materials.

Grinder : For the grinding of the crushed materials.

Separation machine : Separate the materials after being ground.

Collector : Collect and release the dust .

Pulse purifier (air cleaner) : Clean all the dust produced during the operation of the whole system.

Classifying screen :Screen the materials sorted by the separation machine,and screen out oflarger metal materials.

Magnetic machin e : Separate nickel from the metals.

Gravity separator :Separate those finer materials got from the screening machine and separatethe metal completely.

High-pressure blower : Keep the whole system in a negative state so as to collect the materialsand purity the air .

Grinder : For the grinding of the crushed materials.

Separation machine : Separate the materials after being ground.

Collector : Collect and release the dust .

Pulse purifier (air cleaner) : Clean all the dust produced during the operation of the whole system.

Classifying screen :Screen the materials sorted by the separation machine,and screen out oflarger metal materials.

Magnetic machin e : Separate nickel from the metals.

Gravity separator :Separate those finer materials got from the screening machine and separatethe metal completely.

High-pressure blower : Keep the whole system in a negative state so as to collect the materialsand purity the air .

TECHNICAL PARAMETERS

|

Model

|

Capacity

|

|

|

ENVDC-300

|

200-300 Kg/H

|

|

|

ENVDC-500

|

500 Kg/H

|

|

|

ENVDC-800

|

800 Kg/H

|

|

|

ENVDC-1000

|

1T/H

|

|

|

ENVDC-1500

|

1.5T/H

|

|

|

ENVDC-2000

|

2T/H

|

|

|

Feature Item

|

Indicator Requirments

|

|

|

Recovery Rate of Metallic Aluminum

|

>98%

|

|

|

Powder Recovery Rate

|

>98%

|

|

|

Content of Powder In Metal Aluminum

|

<2%

|

|

|

Content of Metallic Aluminum In Powder

|

<2%

|

|

|

Other

|

Contain dust collecter with not pollute

|

|

|

Qualified Rate

|

99%

|

|

|

Failure Rate

|

<1%

|

|

|

CMR

|

≥1.67

|

|

|

WORKING PERFORMANCE

|

|

|

|

Raw Material

|

Lithium Battery

|

|

|

Final Product

|

Mainly Copper, Aluminum, Lithium Cobalt Oxide, Graphite Powder

|

|

NOTE:

The above

lithium-ion battery recycling equipment

is our standard configuration. For different raw materials to be shredded, the configuration might be different.

Please feel free to contact us for detailed information or special request;

Please feel free to contact us for detailed information or special request;

Machine Details

1. Suitable structure and layout, stable performance and recycling water is used to control temperature and reduce noise in the grinder;

2. Lithium Ion Battery Recycling Plant adopts PLC system, electrostatic separator and air makes higher and quicker separation,moreover gets more non-ferrous metal;

3. The negative pressure feeding system prevent the dust from running out, the separation rate of pulse dust cleaning device can reach 99%;

4. The separation rate of air separator can reach 97%, with the magnetic separator, the iron can be separated from other metals.

2. Lithium Ion Battery Recycling Plant adopts PLC system, electrostatic separator and air makes higher and quicker separation,moreover gets more non-ferrous metal;

3. The negative pressure feeding system prevent the dust from running out, the separation rate of pulse dust cleaning device can reach 99%;

4. The separation rate of air separator can reach 97%, with the magnetic separator, the iron can be separated from other metals.

Customer Site

About Us

FAQ

Q: Why Choose Us?

1). We are manufacturer with own factory for many years with CE Certification

2). With professional design and sales team, we can serve you perfect solution with competitive direct factory price.

3). Our machines are popular among customers around the world ( India, Pakistan, Spain, Italy, Korea, Mexico, UK etc).

Q: What Is Our Service?

1). Pre-Sale Service

According to the customers' special requirements,we provide the most suitable project design, process design and the purchase program. Guide customers to choose the best and economical plant, recover investment within short time.

2). Sales Service

You are welcome to visit our factory to test the machine. And we will customize the equipment strictly according to your special requirements and arrange the timely delivery.

3). After-Sale Service

We will provide one year warranty for our machine.According to your need,we will dispatch our engineers to your factory to guide the installation,commissioning and training your workers.

Q: How Do You Ensure The Machine Quality?

A: You can send your sample scrap materials to us and we will test the machine for you without charging the fees. And we can send the machine test video to you. According to your time, you can pay a visit to our factory to test our machine.

Q: How About The Motor?

A: We use domestic Chinese-famous motors,but you can choose Siemens or other brand motor as your requirement.

1). We are manufacturer with own factory for many years with CE Certification

2). With professional design and sales team, we can serve you perfect solution with competitive direct factory price.

3). Our machines are popular among customers around the world ( India, Pakistan, Spain, Italy, Korea, Mexico, UK etc).

Q: What Is Our Service?

1). Pre-Sale Service

According to the customers' special requirements,we provide the most suitable project design, process design and the purchase program. Guide customers to choose the best and economical plant, recover investment within short time.

2). Sales Service

You are welcome to visit our factory to test the machine. And we will customize the equipment strictly according to your special requirements and arrange the timely delivery.

3). After-Sale Service

We will provide one year warranty for our machine.According to your need,we will dispatch our engineers to your factory to guide the installation,commissioning and training your workers.

Q: How Do You Ensure The Machine Quality?

A: You can send your sample scrap materials to us and we will test the machine for you without charging the fees. And we can send the machine test video to you. According to your time, you can pay a visit to our factory to test our machine.

Q: How About The Motor?

A: We use domestic Chinese-famous motors,but you can choose Siemens or other brand motor as your requirement.

Hot Searches