NaN / 0

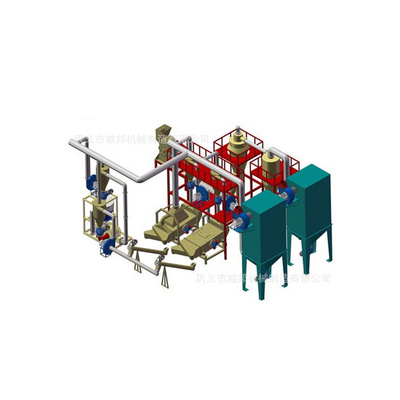

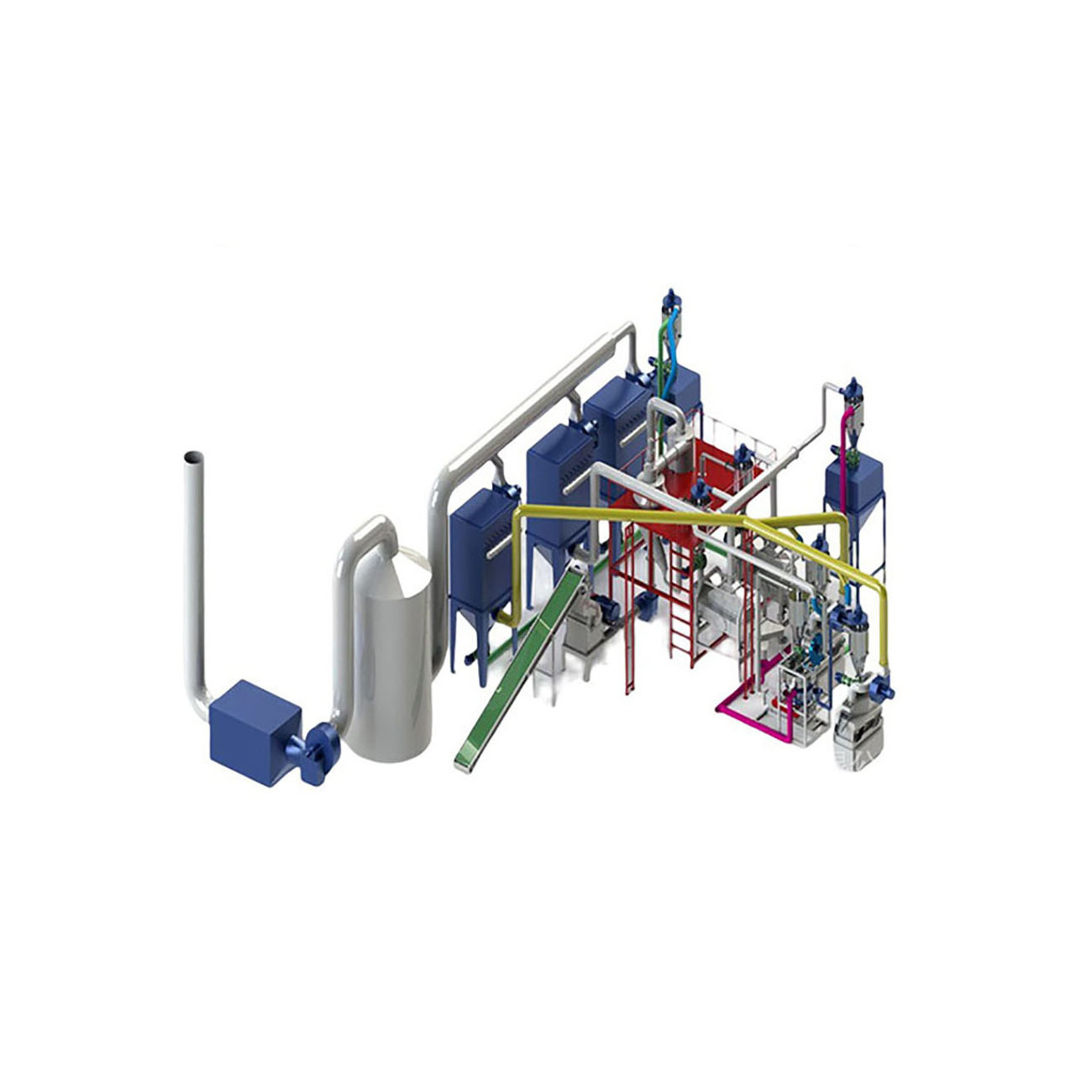

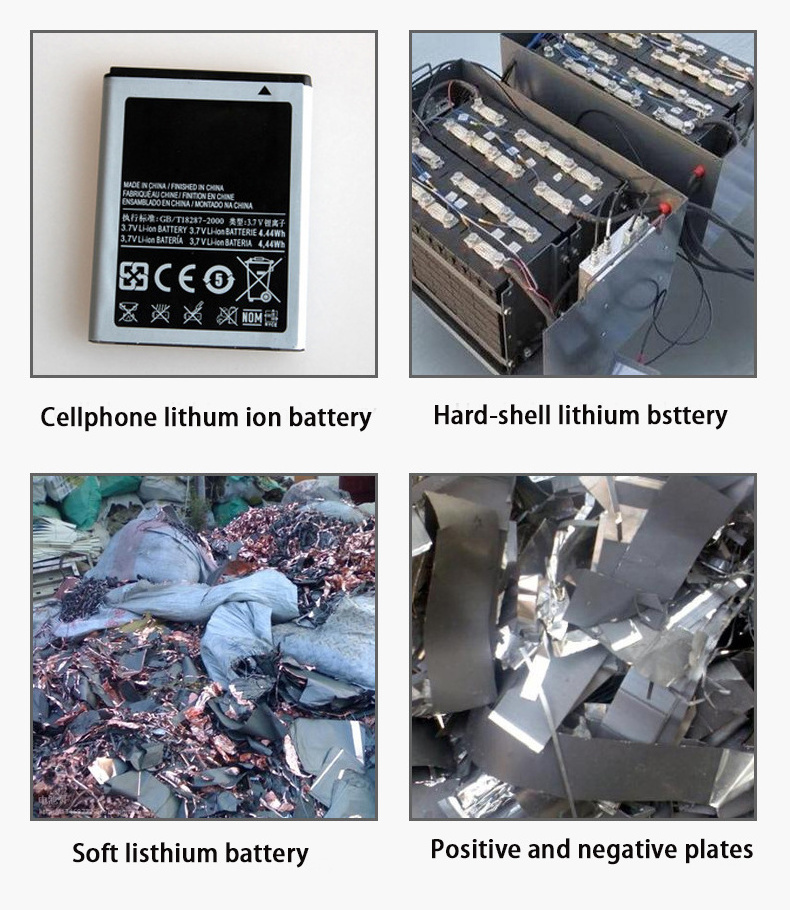

Lithium Battery Recycling Lead Acid Battery Recycling Machine

Get Latest Price

US$ 10000

≥1 Pieces

Quick Details

Production Capacity:

3000L/H

Place of Origin:

Jiangsu, China

Brand Name:

HengKun

Power:

0.25KW

Product Details

|

No

|

Feature Item

|

Indicator Requirments

|

|

1

|

Recovery Rate of Metallic Aluminum

|

>98%

|

|

2

|

Powder Recovery Rate

|

>98%

|

|

3

|

Content of Powder In Metal Aluminum

|

<2%

|

|

4

|

Content of Metallic Aluminum In Powder

|

<2%

|

|

5

|

Other

|

Contain dust collecter with not pollute

|

|

6

|

Qualified Rate

|

99%

|

|

7

|

Failure Rate

|

<1%

|

Lithium battery mainly consists of shell, positive electrode, negative electrode, electrolyte and diaphragm. The positive

electrode is formed by coating lithium cobalt ate powder on two sides of an aluminum foil current collector through PVDF which plays a bonding role;The negative electrode structure is similar to the positive electrode and consists of carbon powder bonded to both sides of the copper foil current collector. At present, the research on the recycling of waste lithium batteries is mainly focused on the recovery of high-value anode precious metals cobalt and lithium. Copper in the negative electrode of waste lithium battery (content up to 35%) is an important production raw material widely used.Carbon powder adhered to it can be used as additives such as plastics and rubber. Based on the structural characteristics of lithium batteries,our company adopts an environmentally-friendly physical separation process to realize efficient separation and recovery of waste lithium batteries.

electrode is formed by coating lithium cobalt ate powder on two sides of an aluminum foil current collector through PVDF which plays a bonding role;The negative electrode structure is similar to the positive electrode and consists of carbon powder bonded to both sides of the copper foil current collector. At present, the research on the recycling of waste lithium batteries is mainly focused on the recovery of high-value anode precious metals cobalt and lithium. Copper in the negative electrode of waste lithium battery (content up to 35%) is an important production raw material widely used.Carbon powder adhered to it can be used as additives such as plastics and rubber. Based on the structural characteristics of lithium batteries,our company adopts an environmentally-friendly physical separation process to realize efficient separation and recovery of waste lithium batteries.

Hot Searches