NaN / 0

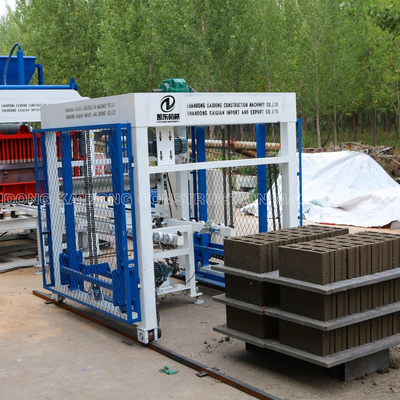

Kaidong QT4-15 Fully Automatic Hydraulic Fly Ash Interlocking Concrete Cement Hollow Sand Mold Brick Block Making Machine

Get Latest Price

US$ 30000

≥1 Sets

US$ 18000

≥3 Sets

US$ 15000

≥10 Sets

Quick Details

Type:

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

Brick Raw Material:

Concrete, Cement, Sand, Crushed Stone, Fly ash

Production Capacity (Pieces/8 hours):

720-840Pieces/Hour For 400*200*200mm Hollow Block

Brick size:

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

Product Details

Product Description

QT4-15 Automatic Concrete Block Making Machine Line

QT4-15 full-automatic concrete block making machine adopts vibration and hydraulic pressure combination. It has high pressure and block making speed. The automatic material feeding system adopts 360 degree rotating feeding method. The feeding course is done at one time with high finished block density and speed. Pallet is feeding automatically and the block is delivering by the front chain.

This machine is suitable for customers who mainly produce standard bricks and blocks. Can produce high number of blocks at single time with fast speed and good hydraulic pressure. This machine uses computer PLC central control system, which can realize automatic mixing, material feeding and moulding.

|

QT4-15 Automatic Block Making Machine Technical Parameters

|

|

|

|

|

||||

|

No.

|

Size

(L*W*H)

|

Pieces/Mould

|

Pcs/Hour

|

Pcs/Shift

|

||||

|

1

|

400* 200* 200mm

|

4

|

720- 840

|

5760- 6720

|

||||

|

2

|

400* 100* 200mm

|

8

|

1440- 1680

|

11520- 13440

|

||||

|

3

|

400* 150* 200mm

|

5

|

800- 900

|

6400- 7200

|

||||

|

4

|

400* 250* 200mm

|

3

|

540- 630

|

4320- 5040

|

||||

|

5

|

230* 110* 70mm

|

24

|

4320- 5040

|

34560- 40320

|

||||

|

6

|

200* 100* 60mm

|

16

|

2880

|

23040

|

||||

|

7

|

200* 163* 60mm

|

10

|

1500

|

12000

|

||||

|

Mainframe Dimension

|

|

|

4000* 1800* 2800mm

|

|

||||

|

Pallet Size

|

|

|

1020* 570* 25mm

|

|

||||

|

Vibration Method

|

|

|

Hydraulic+ Vibration

|

|

||||

|

Moulding Period

|

|

|

15 Seconds

|

|

||||

|

Vibration Frequency

|

|

|

4500-5100 Times/Min

|

|

||||

|

Feeding Hopper Volume

|

|

|

0.5m

3

|

|

||||

|

Mainframe Motor Power

|

|

|

27KW

|

|

||||

|

Hydraulic Pressure

|

|

|

25Mpa

|

|

||||

|

Operation Pressure

|

|

|

18-20Mpa

|

|

||||

|

Mainframe Weight

|

|

|

5.8Tons

|

|

||||

Main Features

1: Computer PLC central control system can realize automatic production.

2: Four-bar guiding method and super-long guide bearing are adopted to ensure the precise movement of the up mould.

3: The machine body is made of super-strength steel materials and special welding technology. It is strong and durable in vibration.

4: It's quick to change mould for producing cement products of different specifications and shapes such as pavement bricks, curbstones, hollow blocks, standard bricks, etc.

5: Seals and some hydraulic components are imported from Europe, the comprehensive performance of the equipment is stable and reliable.

6: The motor adopts the national inspection-free motor (pure copper core), and the hydraulic station adopts the special components for large hydraulic machinery.

7: Mechanical transmission, compact result, convenient maintenance, flexible operation and good reliability.

8: Up and down pressure, strong vibration, especially in the production of heavy bearing high-strength blocks (strength up to 20 MPa).

9: The finished product has high strength, good compactness, precise appearance size, regular shape, no burr and angle drop.

10: Large amount of fly ash, cinder and various waste residues can be used for materials with high efficiency.

11: Small investment, quick results, suitable for different national conditions.

Detailed Images

Mainframe

Name: QT4-15 Concrete Block Making Machine

Brand: KAIDONG

Original: China

The production capacity depends on this forming machine and it is also the essential part of the whole production line. You can change moulds on this parts to make different shaps of blocks, bricks, colored-paving stones and curbstones.

• The process is controlled by PLC and fitted with remote control device. for PLC control system, we usually use Japan Mitsubishi or Taiwan Brand.

• The electricity motor for host machine we use Germany Siemens motor, for other parts, we use CE motor.

• About the switches, we will use France Schneider or China CHNT.

• Rakes in several rows make sure raw materials fed well-distributed.

• Hydraulic components we use Taiwan JiuGang famous brands.

• The demoulding synchronizer avoids the damage to concrete products.

• The vibration system contain two part, one is up-mould vibration box, it is electricity motor to supply the power for up-mould vibration box. And the down mould, there is one big vibration. When the scatter material work is finished, the hydraulic power with the two vibration power will assure the good quality for product.

• The mould is processed with carburizing, nitriding, wolfram carbide and quenching which ensures its strength reach to 54~58 HRC and can be used 100 thousand times.

Mixer

Name: JS500 Horizental Double Shaft Concrete Mixer

Brand: KAIDONG

Original: China

Before using, connecting to the power source (according to the local power source inquirement). Put 8kg machine oil into gear case. Then, make the machine work for 5mins without anything. The next step, put the material (granules and glue) into the container. It takes 5-6mins to finish the mixing. After using, please clean the container.

Global Vision

Certifications

Our Factory

KAIDONG MACHINERY

SHANDONG KAIDONG CONSTRUCTION MACHINERY CO.,LTD(SHANDONG KAIQIAN IMPORT & EXPORT CO.,LTD) are professional building materials machinery and equipment research, manufacture and export company. Company business started in 1998, year turnover is more than 50 million USD. The company's main products are concrete block making machine, AAC block machine, concree pole pipe making machine, concrete roof tile machine and mixer.

The company passed ISO9001 management system and the European Union CE certification, the products absorb the German mechanical design and manufacturing experience, focus on quality design, high-quality material, exquisite welding and strict inspection process to ensure high-quality equipment and maximize service life. Company products are exported to Southeast Asia, Africa, South America, Eastern Europe, the Middle East, Australia and more than 90 countries and regions.

Company of "integrity first, win-win cooperation", the positive development of quality products, improve the quality of service. We are not only the machinery products supplier, most important is that we are best program and service supplier according to clients real conditions. Welcome all customers to cooperate with us.

Packing & Delivery

Contact

If you have interest about our machine, you are welcome to contact:

+8

6

15715399256

.

It's available at Whatsapp, Wechat, Messenger, Line, Telegram, imo and many other APPs.

My e-mail address is: even@kaidongmachine.com.

Office address: Comprehensive Bonded Zone, Lingong Road No.100, Linyi City, Shandong Province, China

Hot Searches