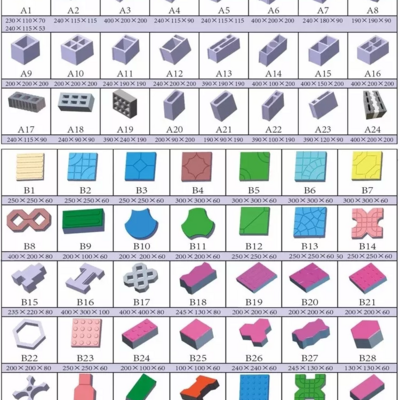

Full automatic block paver brick block making machine adopt to hydraulic pressure moulding system , so the brick machine has more stable and higher-efficiency working status and the bricks produced are of better quality, larger density and higher strength.