NaN / 0

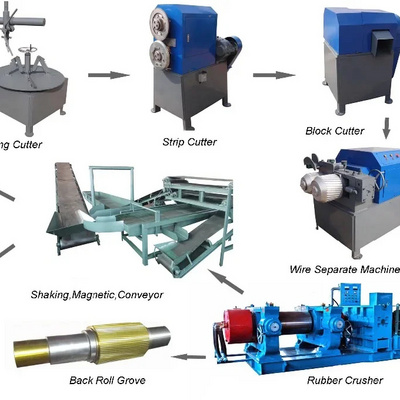

Recycling rubber tyre machine tire shredder to make rubber powder price

Get Latest Price

US$ 30000

≥1 Sets

US$ 29000

≥2 Sets

US$ 28000

≥3 Sets

Quick Details

Place of Origin:

Henan, China

Brand Name:

HENGJU

Voltage:

220V

Dimension(L*W*H):

whole line about 35*25*5meters

Product Details

Instruction:

1.To granulate radial tires into fine rubber crumb of 40~120 mesh with steel and fiber completely recycled at ambient temperature.

2.The input is whole tires,after the processing,steel is completely separated and fiber can be separated up to 99% or above.The finish product is high and competitive in the market

3.Tight construction, small space and simple technique flow.

4. Low energy-consuming and good performance-cost ratio

5.Hight automatization, fewer labours requirement.

6.Reasonable construction,easy operation and low rate of breakdown

7.Environmental-protection,no pollution(no waste gas,no waste residue,no polluted water),meeting the environmental requirement of the government.

Tire cutter is designed to cut car, truck and rear tractor tires. Range is up to 2000 mm truck tires.

Raw material: 900-1200mm tire

Finished material: 2-4PCS of tire blocks

Production Capacity: 40-60 tire/hour

Pulling force: 13T

Max. Tyre diameter: ≤1200mm

Main motor (kw): 5.5

U sed for :

We have the following three production lines for you to choose from. If you want to know more details, please contact me in time. Of course, we can also customize a suitable plan for you according to your needs.

| The production line | Capacity (t/h) | Total Power (kw ) |

| 1 | 300 kg | 50 |

| 2 | 500 kg | 70 |

| 3 | 1000 kg | 120 |

Company introduction

- Zhengzhou hengju machinery equipment co., LTD is located in zhengzhou city, the famous historical and cultural city of henan province. The company is a mechanical equipment technology and research and development, sales in one enterprise.

- The company always adheres to the principle of "scientific and technological development" and always adheres to the business philosophy of "reputation first and service first", and pursues the enterprise tenet of "people-oriented, scientific and technological development". To comply with each order; Responsible for the quality policy of each user. For the majority of users to provide more advanced, better quality, more cost-effective products. There are more timely, faster and more intimate services to solve your problems at any time. In the process of the company's development, the heavy industry has formed a unique and rich enterprise culture. Hengju machinery and you sincerely cooperate to create a brilliant tomorrow.

Hengju machinery deeply practices "made in China 2025", and USES technology and service to help manufacturing enterprises to upgrade intelligently.

In Internet + 4.0 dual core and industrial, driven by dawn heavy industries will be based on the major demands of industrial age of the Internet, provides the industry's leading intelligent technology and service, focused and industry chain partners with leading technology and service support the development of manufacturing, helping our clients achieve the value of the higher and faster growth.

EQUIPMENT

High precision machine tool production equipment,The products produced by it are more accurate.

PACKING AND SHIPPING

We usually pack one set of oil fress machine into one wooden case,and then put wooden cases in container Our goods' transportion is very flexible,we can shipping by air or by sea.

We usually produce 300-500 sets oil press machine per month,and our stock is abundant.

CUSTOMER VISITING

Customer feedback

Our Service & FAQ

FAQ

1. Are you manufacturer or trading company?

We are manufacturer with 35 years experience on machines. HENGJU machines were exported to more than 20 countries, supplying full technical support and solutions, timely and professional service.

2. How do you assistant to install the machine on worksite?

We are experienced on turn-key project, engineer and technicians will assistant client on construction, installation, commissioning.

3. How can I get spare parts for replacement in other countries?

Wearing parts like blades, it is necessary to buy with machine, other parts in stock could be delivery out by express if urgent or by sea within 5days.

4. Can I use mark machine with different logo and color?

Yes, please confirm details with sales.

5. Can your customers test the machines?

Before the machines or production line leaving factory, we test machine for client with free of charge.

6. What will we do if we have problems in machine working after we buy the machine?

Luodate has people special for after-sale service, if customers outside China have problems when machine working, just feel free to send us the picture or video to show us, we will give you solutions in 24hours.

Chat Online

Hot Searches