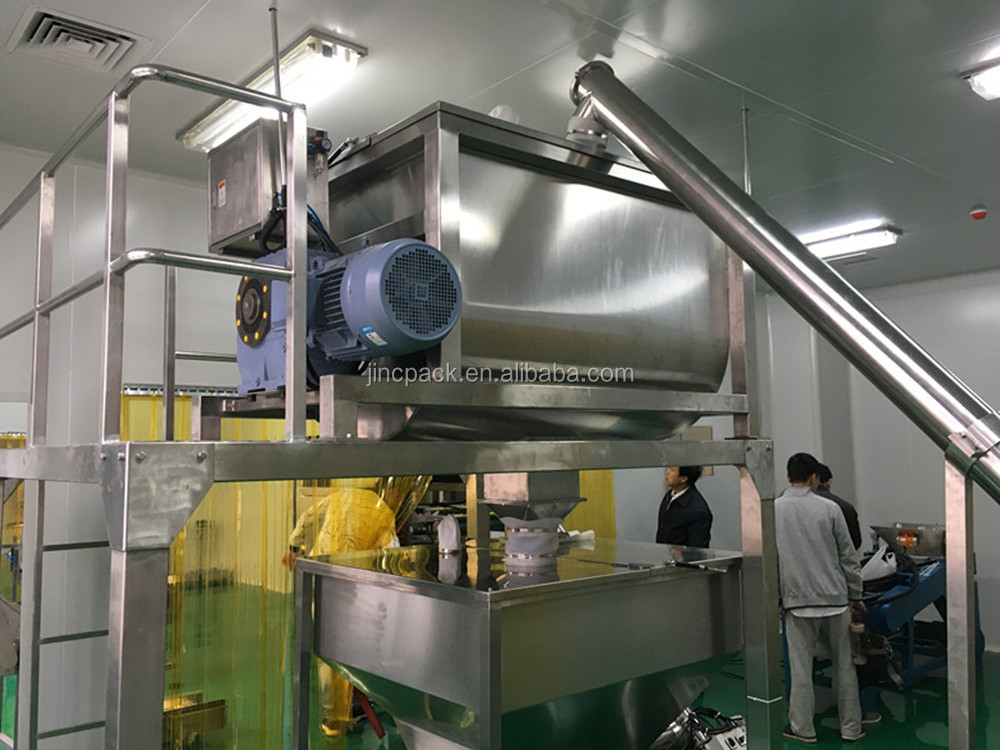

The machine consists of U-shaped containers, ribbon mixing blade and transmission component. Ribbon mixing blades are usually made into double or three layer. The outer helix collects the material from both sides to the center, and the inner helix conveys the material from the center to both sides, forming a convective mixing. The ribbon mixer has a good effect on the mixing of viscous or cohesive powder particles and the mixing of powder particles material added liquid or paste materials. The cover can be made into a fully open door to facilitate cleaning equipment and replace the product.