NaN / 0

6000 L WZL-6 double shaft paddle fertilizer mixer mixing machine

Get Latest Price

US$ 10000

≥1 Sets

US$ 8000

≥5 Sets

US$ 6000

≥10 Sets

Quick Details

Barrel Volume (L):

6000 L

Max. Loading Volume (L):

3600 L

Range of Spindle Speed(r.p.m):

1 - 35 r.p.m

Max. Loading Capacity:

60%

Product Details

Introduction

Introduction:

Double shaft mixer is widely applied in chemical, biological, and construction material. It can mix powder, granule, and fiber especially in battery, construction, environmental, mineral and agricultural line.

Product features:

With the most powerful motor, material can be mixed evenly in the shortest time. It is particularly good at mixing material with big difference in gravity, mesh size, fluidity.

1.material selection

Material can be carbon steel, manganese steel, ss304, 316L and 321; besides, different material can also be used in combination between the part contact with the raw material and the parts don’t contact with the raw material.Surface treatment for stainless steel include sandblasting, wiredrawing, polishing, mirror polishing, all can be used in different parts of a mixer.

2.driven unit

The driven unit, power and speed are varied according to different raw material, starting method, and processing.Because of the meshing relationship for the paddles, the double shaft driven unit is required to be equipped with synchronous ability. The four different driven combination launched by Shengli Co. can meet different requirements of two synchronous gear box, double output gear box, double synchronous planetary gear box, and the combination of reducer and chain.The combination of Sk-series double synchronous gear box is the best configuration for double shaft paddle mixer.

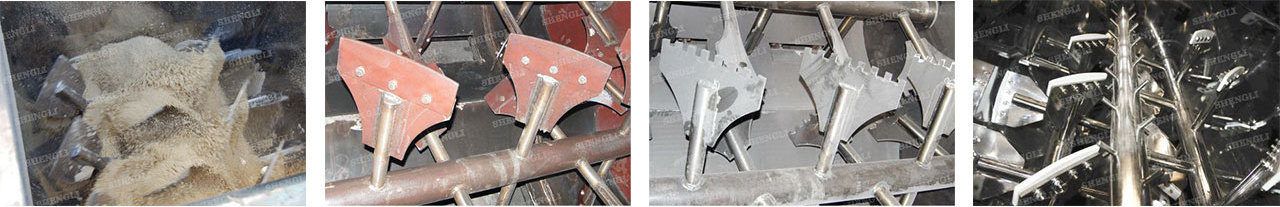

3.mixing unit

According to the properties of raw materials, the paddle can be adjusted and designed accordingly, for example adding wear-proof plate, Teflon plate, and saw-toothed paddle.Double shaft paddle mixer can be also added high speed breaking bar inside the barrel, scattering material following its flow.

4.discharging unit

Standard valve for double shaft paddle mixer is twin pneumatic planar flap valves. When close the valve, the planar flaps match the mixing barrel perfectly, this makes no mixing dead zone and better mixing effect.

Working Principles

Double shaft paddle mixer is a batch mixer with two counter-rotating shaft that are equipped with ten paddles, they overlap each other following the driven unit,Blades generate centrifugal force during high speed rotation, spilling the material to the upper part in the barrel, then material falling down (the vertex of material is in a so-called instant non-gravity state). Driven by the blades, material is mixed back and forth; also sheared and separated by the meshing space between the twin shafts; fast and evenly mixed in the end.

Specification

Selection way:

1. Choose the batch working capacity from 0.1cbm to 20cbm, select mixer accordingly.

2. Choose raw material for the part contact with raw material, non-contact with raw material, other parts like motor and reducer,bearing material can not be chosen; According to the material to be mixed, processing condition, health level, raw material can be chosen from mild steel, sus304, sus316L, sus321; And choose the surface treatment according to the raw material.

3. Motor power is chosen according to the material gravity, fluidity, and operation.

Operation is divided as: Start mixer when it is empty (normal duty); Start mixer with load (heavy duty)

4. Adding the auxiliary components like spraying, heating and cooling according to processing condition.

5. Mixer inlets: feeding ports, cleaning port, vent.

6. Chose discharging and driven mode: manual, pneumatic and electric.Note: mixer selection is a very important step, your detailed material information, processing and factory arrangement is very helpful to get professional technical support from us.

2. Choose raw material for the part contact with raw material, non-contact with raw material, other parts like motor and reducer,bearing material can not be chosen; According to the material to be mixed, processing condition, health level, raw material can be chosen from mild steel, sus304, sus316L, sus321; And choose the surface treatment according to the raw material.

3. Motor power is chosen according to the material gravity, fluidity, and operation.

Operation is divided as: Start mixer when it is empty (normal duty); Start mixer with load (heavy duty)

4. Adding the auxiliary components like spraying, heating and cooling according to processing condition.

5. Mixer inlets: feeding ports, cleaning port, vent.

6. Chose discharging and driven mode: manual, pneumatic and electric.Note: mixer selection is a very important step, your detailed material information, processing and factory arrangement is very helpful to get professional technical support from us.

Accessory Project

Placing in the production line, and combined with raw material silo, dosing system, conveying system, production silo, and packer,the non-gravity mixer can achieve the scale production. All equipments in the production line should be placed and coordinate with each other reasonably to realize the most efficient production.

Configuration 1: vacuum feeder, storage silo under the mixer, and a packer under silo.

Configuration 2: manually feed with the folk lift, bulk-bag packer under the mixer.

Configuration 3: manually feed, discharged to conveyed to storage silo, then packing.

Configuration 2: manually feed with the folk lift, bulk-bag packer under the mixer.

Configuration 3: manually feed, discharged to conveyed to storage silo, then packing.