NaN / 0

Waste wood firewood biomass coal fired thermal oil boiler for plywood industry

Get Latest Price

US$ 10000

≥1 Sets

Quick Details

Core Components:

boiler body

Steam Production:

240kw to 28000kw

Place of Origin:

Henan, China

Brand Name:

Yuanda

Product Details

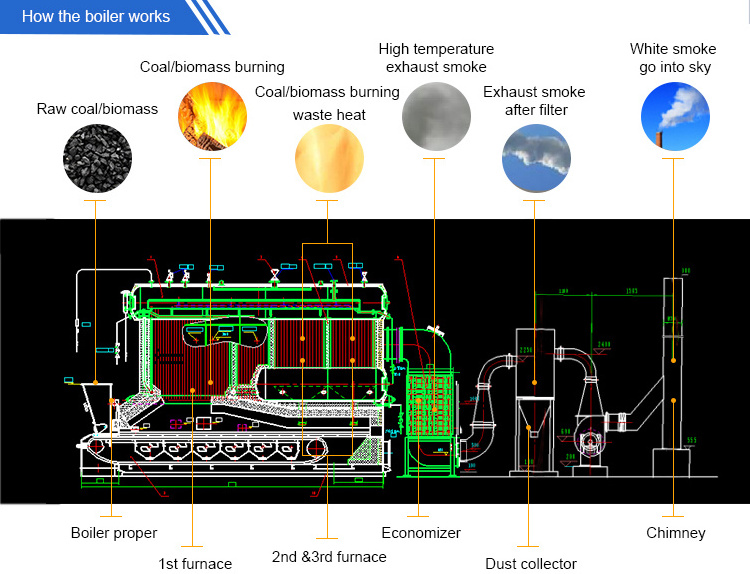

Products Description

Rated capacity:

350KW to 14000kw

Rated output temperature:

280℃/320℃

Applicable fuel:

coal,biomass pellet, wood,etc

|

Item

|

Unit

|

Boiler model

|

|

|

|

|

|

||||||

|

|

|

YLW-700

|

YLW-1400

|

YLW-2400

|

YLW-2900

|

YLW-4200

|

YLW-7000

|

||||||

|

Rated capacity

|

KW

|

700

|

1400

|

2400

|

2900

|

4200

|

7000

|

||||||

|

Rated pressure

|

Mpa

|

0.8

|

|

|

|

|

|

||||||

|

Output temperature

|

℃

|

280/320

|

|

|

|

|

|

||||||

|

Input temperature

|

℃

|

250/290

|

|

|

|

|

|

||||||

|

Circulating flow

|

m3/h

|

45.7

|

87.4

|

149.8

|

155

|

225

|

383.467

|

||||||

|

Heat carrier volume

|

m3

|

0.46

|

1.19

|

2.08

|

2.73

|

4.36

|

7.06

|

||||||

|

Thermal effiency

|

%

|

80

|

80

|

81

|

82

|

83

|

83

|

||||||

|

Applicable fuel

|

coal and biomass

|

|

|

|

|

|

|

||||||

|

Fuel consumption

|

kg/h

|

187

|

373

|

621.3

|

756

|

1189

|

2052

|

||||||

|

Exhaust temp.

|

℃

|

224.8

|

201

|

166.02

|

167.8

|

142.96

|

137.12

|

||||||

|

Size

|

mm

|

4800×2100×2900

|

6050×2530×3460

|

6300×3100×3750

|

6970×2730×3760

|

8800×3410×5110

|

10100×3300×2860

|

||||||

|

Weight

|

Ton

|

16.9

|

22

|

28.6

|

24.2

|

30

|

18.2

|

||||||

|

Notice

|

1. As the palace is limited, we only list part of our coal/biomass fired boiler models.If what you need is not in the datasheet,

pls send us inquiry for specifics. 2. the pharmater is for reference,of technology is improved, please refer to the data showed on general drawing. |

|

|

|

|

|

|

||||||

Pre-sale service:

1.Provide the most suitable and cost-effective boiler solution according to different requirements of various industry.

2.Provide drawings for building your boiler roon,such as foundation drawing, layout drawing, boiler room layout, etc.

In-sale service:

24 hours online and keep close contacts during the production process to ensure on time delivery with perfect finished product. We send pictures and videos to let customers know the production schedule.

After-sale service:

1.provide full range of original spare parts.

2.Provide engineers abroad installation and commissioning service.

3.Held online or site training for boiler workers to ensure the safe operation.

4.Free maintenance and repair for one year and lifelong service.

2.Provide engineers abroad installation and commissioning service.

3.Held online or site training for boiler workers to ensure the safe operation.

4.Free maintenance and repair for one year and lifelong service.