NaN / 0

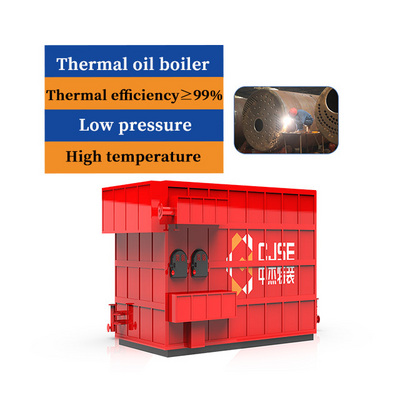

Coal / Oil/ Gas/ Biomass Fired Thermal Oil Boiler at Good Price

Get Latest Price

US$ 9999999

≥1 Sets

Quick Details

Place of Origin:

Henan, China

Brand Name:

Dafu

Dimension(L*W*H):

as the modle

Weight:

Models

Product Details

Coal / Oil/ Gas/ Biomass Fired Thermal Oil Boiler at Good Price

Product Description

heat-conducting oil boiler

Application

Building materials industry: road bitumen heating, gypsum board drying, heating bitumen concrete, concrete elements curing, drying equipment. and other industries.

Heat-conducting oil boiler refers to a boiler heated by heat-conducting oil. Heat transfer oil, also known as organic heat carrier or heat medium oil, has been used as an intermediate heat transfer medium in the industrial heat exchange process for more than 50 years. A once-through boiler developed based on the design concept of forced circulation. Generally, coal, oil, and steam are used as fuel, heat transfer oil is used as the medium, and the hot oil circulating oil pump is used to force the medium to circulate in the liquid phase. The heat energy is transferred to the heating equipment and then returned to the heating furnace for reheating. High working temperature, and can carry out high-precision control of the operation of the medium.

Features

1. It has the characteristics of low pressure, high temperature, safety, high efficiency and energy saving.

2. It has a complete operation control and safety monitoring device, which can precisely control the working temperature.

3. Reasonable structure, complete supporting facilities, short installation period, convenient operation and maintenance, and convenient boiler layout.

4. Because the electric heating organic heat carrier furnace adopts advanced explosion-proof structure, it can be applied to the explosion-proof zone II of the factory, and the explosion-proof grade can reach C level.

specification:

|

Model |

YGL-1000 |

|

Data |

800,000 |

|

Parameter |

1000 |

|

Design pressure |

1.0 Mpa |

|

Highest operating temperature |

320ºC |

|

In the stove the oil accommodate |

1.3 m³ |

|

Heat transfer area ( Square Meters ) |

63.8 |

|

Leaves |

Liquid phase |

|

Design fuel |

Coal |

|

Fixed thermal power |

75%(86%) |

|

Circulation oil mass |

80m³/h |

|

Actuating medium |

Heat conducting oil |

|

Coal consumption |

160kg/h |

|

Oil consumption |

80kg/h |

|

Gas consumption |

96m³/h |

|

Tubing connection caliber DN |

125 |

|

Outlook size |

2100mm×3780mm |

|

Drawing fan electrical machinery model/power |

Y112M-2/4 |

|

Circulation pump electrical machinery model/power |

Y160M/15 |

Packaging & Shipping

|

Packaging Details: |

standard export packing, 20ft, 40ft container. equipment fittings,electric motor and power cabinet will be packed in wooden case. bulk

|

|

Delivery Detail: |

30 working days after receiving the payment

|

Each boiler has certification issued by the official.

Note

O ur company can design all kinds of Gypsum equipments and boiler to satisfy different uses for the clients.

welcome to customize