NaN / 0

Baichy Mining Machine Full Placer Gold Processing Wash Plant Rock Gold Ore Small Scale Gold Mining Machine Beneficiation Plant

Get Latest Price

US$ 98000

≥1 Sets

Quick Details

Production Capacity:

0.037-4 m³/cell

Place of Origin:

Henan, China

Brand Name:

Baichy

Voltage:

According to the model

Product Details

Baichy Mining Machine Full Placer Gold Processing Wash Plant Rock Gold Ore Small Scale Gold Mining Machine Beneficiation Plant

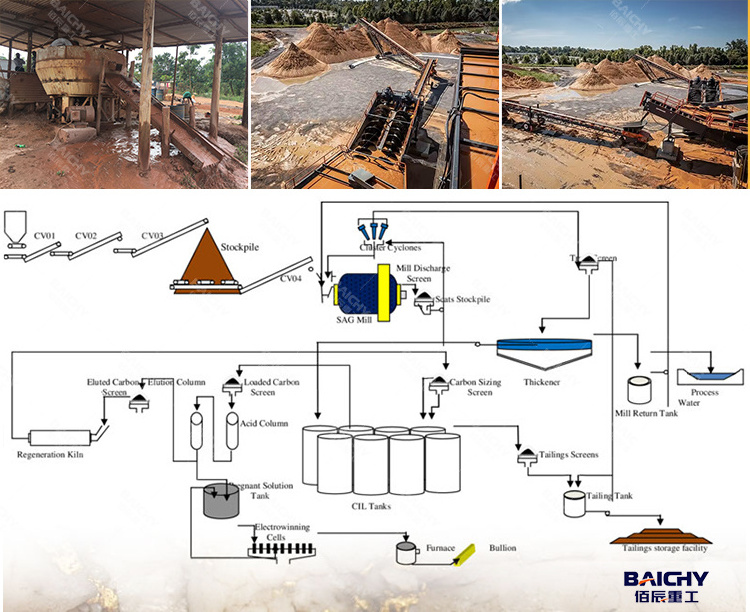

The gold ore beneficiation process includes the gravity separation and flotation process, gold cip, cil process, and gold heap leaching, all of which can realize high-efficiency recovery of gold. The beneficiation process and relative equipment are chosen according to the nature of the gold ore. Baichy could provide you with a complete set of gold processing solutions and equipment according to the specific types of gold mines.

Our factory produces full sets of mining equipment for processing gold, diamond, gemstone, coltan, chromite, zircon, rutile, magnetic iron ore, lead, zinc, tin, tungsten, copper, gem, titanium ore, rare earth, tantalum, niobium, chrome, etc.

>>> Gold Ore Processing Plant Introduction

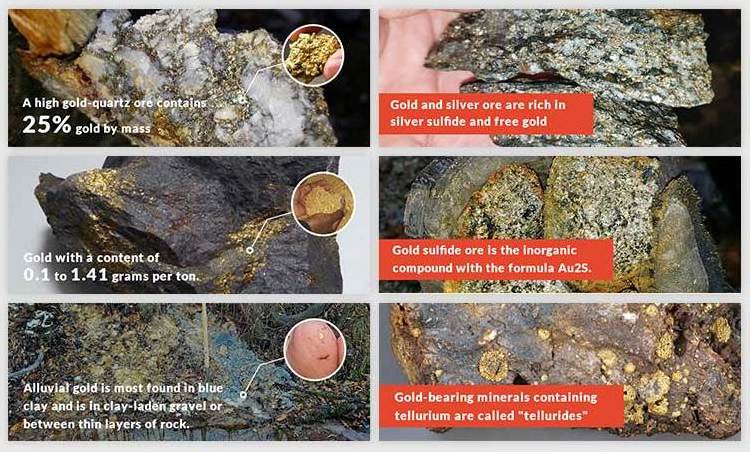

Gold exists in quartzite. Usually, quartz appears as small stones in large cracks in riverbeds or mountain slopes and has crystals in different colors such as white, yellow, pink, purple, gray, or black. The most common types of quartz with gold ore are rose quartz gold ore and rainbow gold ore. A high gold-quartz ore contains 25% gold by mass, and it occurs in areas where the bedrock is fractured by tectonic and volcanic activity.

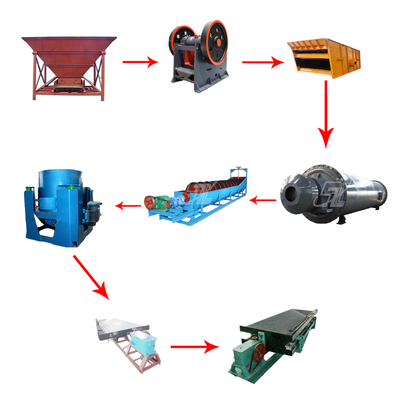

Gold processing plants are common including crushing, grinding, and beneficiation process.

Step 1: Crushing

Due to the raw ore size is large, it is necessary to be crushed into suitable particles. The loader sends raw ore into a vibrating feeder, which feeds material evenly to the jaw crusher for the primary crushing process. In the ore beneficiation plant, one important rule is to crush more and grind less. If necessary, a cone crusher or hammer crusher could be added as a second crushing process to get suitable particles.

Step 2:Grinding

After crushing, the material goes into a ball mill via a feeder for fine sizes, such as 325mesh. The ball mill and spiral classifier is a closed-loop circle. The material after ball mill grinding comes into a classifier for classification. Qualified fine ore is into the next process and unqualified coarse ore is returned back to the ball mill for grinding again. In this grinding process, we must first make clear the requirements for each ore particle standard.

Step 3: Selecting

In the production process, not all the ore powder are in line with the standard. The useful ore powder needs to be selected via professional equipment, such as a mixing tank, flotation machine, shaking table, spiral chute, etc. Then the qualified concentrate powder from the ore is stocked in a settling pond.

>>> Related Equipment Of Gold Processing Plant

The complete gold ore beneficiation process includes crushing, grinding, and beneficiation process. The main equipment is a jaw crusher, vibrating screen, feeder, ball mill, spiral classifier, mixing tank, flotation machine, centrifugal gold machine, shaking table, etc. We could provide you with a complete set of gold processing solutions and equipment according to gold mine types.

|

||

Pre-sale services:

(1) Advice on model choice.

(2) Design and manufacture machines according to customer's special requirements

(3) The company is free of charge to the user on-site engineering and technical personnel planning site for the user to design the best processes and program

After-sale services:

(1) Arrange technicians to go to the site to guide the installation

(2) If your machine is out of warranty period, Baichy could provide the spare parts.

(3) Complete sets of equipment installed, Baichy could arrange technical staff on-site for installation, debugging, and training until the user's satisfaction.

20 national service mileage:

Service mileage for local customers to provide equipment installation, commissioning, and after-sales service

Baichy headquarters is located in the industrial park in Jiaozuo City. It covers a total area of 200,000 square meters, including 150,000 square meters of standardized workshops. There are more than 200 sets of various large and medium-sized metal processing lathes, riveting machines, welding equipment, and assembly equipment. We have more than 500 workers, including more than 20 middle and senior technicians. Baichy is mainly focused on 4 series of products: stone crusher machines, sand-making equipment, powder grinding mills, mineral processing equipment, and their spare parts. Every year, Baichy can turn out 1,000 sets of crushers and 10,000 tons of crusher parts.

1. Are you a manufacturing or trading company?

We are a factory, established in 2003.

2. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

3. What is your payment method?

30% deposit in T/T advance, 70% balance before shipment.

4. How long is the warranty? Does your company supply the spare parts?

One year. Spare parts for you at the lowest cost.

5. If I need the complete crushing plant can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already built many mining projects in China & Overseas.

Hot Searches