NaN / 0

Au Wash Plant Mining Machine Gold Trommel Screen Gold-Processing-Plant Small Scale Gold Wash Plants

Get Latest Price

US$ 6500

≥1 Sets

US$ 5100

≥10 Sets

Quick Details

Production Capacity:

99%

Place of Origin:

Jiangxi, China

Brand Name:

JXSC

Voltage:

380v or customized

Product Details

Product Description

Overview

▼

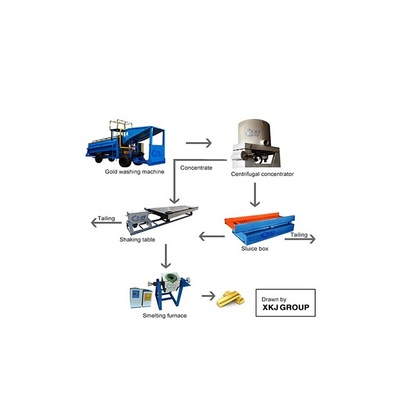

The separation principle of alluvial gold is to use gravity separation to recover the most of gold and its associated heavy

minerals from the raw ore first, and then use gravity separation, flotation, amalgamation, magnetic separation, electric

separation and other combined actions to separate gold and heavy minerals from each other to achieve the purpose of comprehensive recovery.

minerals from the raw ore first, and then use gravity separation, flotation, amalgamation, magnetic separation, electric

separation and other combined actions to separate gold and heavy minerals from each other to achieve the purpose of comprehensive recovery.

Alluvial Gold Washing Plant Without Sticky Clay:

Ore: Alluvial gold without sticky clay

Capacity: Customized Equipment

Used: Trommel screen + jig machine + sluice box + shaking table + gold amalgamator + gold smelting machine.

Processing:

1. The raw ore feed into the trommel screen for washing a few little

clays, and can separate the gravel or stone which do not contain the gold inside, which can transfer away by the belt conveyor.

clays, and can separate the gravel or stone which do not contain the gold inside, which can transfer away by the belt conveyor.

2. The jig machine for catching the big particle around 2-20mm bigger gold particles or nuggets, and a sluice box capture the gold particle or nuggets again in case they flow away from the tailings. Please note the sluice box can be designed with different lengths and widths like 2m,4m,6m length,1m width or 0.5m width, etc.,

3. The concentrates under the jig machine go to the shaking table again for a more good separation effect. Because the concentrates still have a little sand. Use the shaking table can separate the sand from the gold in very good effect. This washing plant is very suitable for recovering alluvial gold ore that doesn’t contain sticky clay. If the raw ore contains much sticky clay, we will recommend a trommel scrubber instead of a trommel screen.

The capacity for this washing plant can be customized as per request such as 10tph,50tph,100tph, etc.,

Placer Gold Processing with Sticky clay ▼

Ore: Placer gold with sticky clay

This flowchart is suitable for any type of alluvial ores, especially placer gold with sticky clay, gold particles with 5mm below.

If the gold particle size is bigger than 5mm, just add one more sluice box for recovering gold nuggets with 5mm up.

Capacity: Customized Equipment Used: Trommel scrubber + vibrating feeder + centrifugal concentrator + slurry pump + sluice box + shaking table

Processing:

1. Loader or Excavator feed raw ore into the hopper;

2. Vibrating feeder feed trommel scrubber. Trommel scrubber is to wash off clay from ore, and screen out different sized particles.

3. Overscreen materials of trommel are transported to far place by belt conveyor, this is waste sand.

3. Overscreen materials of trommel are transported to far place by belt conveyor, this is waste sand.

4. Under screen materials of trommel are sent to the centrifugal concentrator by a slurry pump, Centrifugal concentrator is to concentrate 0-5mm fine gold.

5. Tailings of centrifugal concentrator will be sent to sluice box for recovering more gold.

6. Concentrates of sluice box and centrifugal concentrator are sent to shaking table for fine concentration gold in order to increase the purity of gold content.

This flowchart is suitable for any type of alluvial ores, especially placer gold with sticky clay, gold particles with 5mm below.

If the gold particle size is bigger than 5mm, just add one more sluice box for recovering gold nuggets with 5mm up.

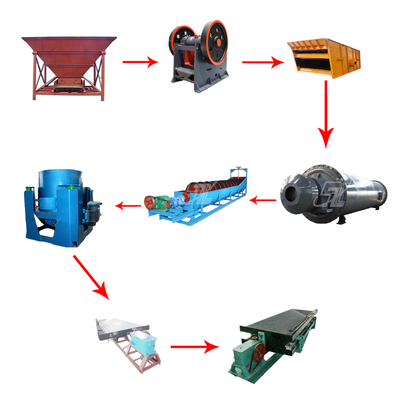

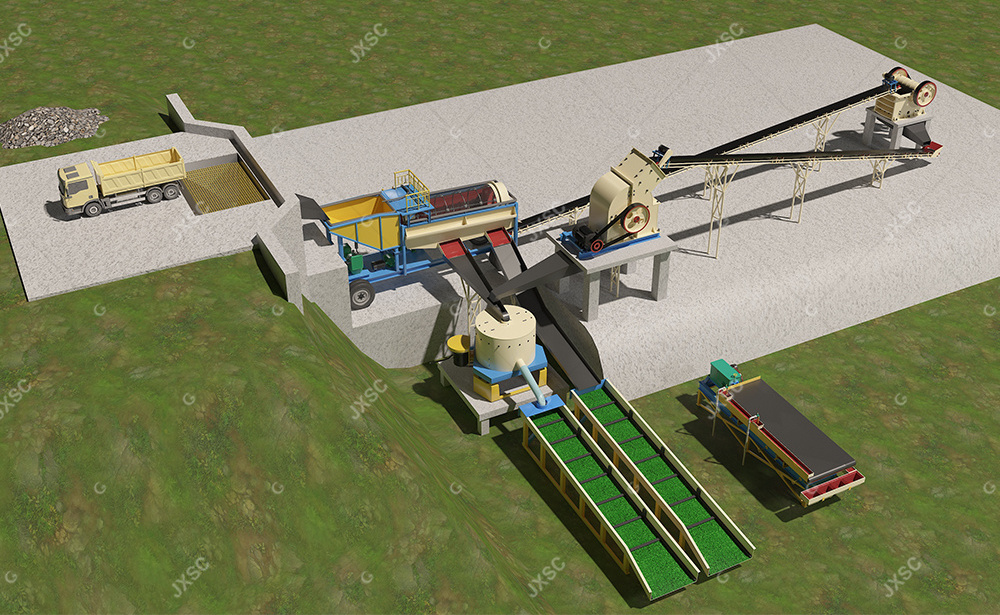

Alluvial & Rock Gold Plant ▼

Ore: Alluvial gold and rock gold

Capacity: Customized Equipment Used: Trommel screen + gold concentrator + sluice box + belt conveyor + jaw crusher + hammer crusher + shaking table

Processing:

1. The raw ore feeds into the trommel screen for washing a few little clays and can separate the gravel or stone which need to crush & grind to get the inside gold. The separated gravel can transfer to the next jaw crusher by belt conveyor.

2. The trommel screen is designed with two layers screen, the bigger than 20mm to a jaw crusher, which can crush the big stone into smaller parties.

3. The output from the jaw crusher goes to the hammer crusher via the belt conveyor.

4. The hammer crusher the smaller stone less than 2mm to release the inside gold.

5. The medium particle size is around 6-20mm. Which contain gold nuggets goes to sluice box to capture the nuggets by the sluice carpet directly.

6. The smaller size <6mm goes to the gold concentrator for catching the gold first, the concentrated from the gold

concentrator goes to the shaking table for separating the gold again to update the recovery rate.

concentrator goes to the shaking table for separating the gold again to update the recovery rate.

For this flowsheet, the trommel screen is designed with mobile wheels, which can easily move from one site to another site. Or you can choose a stationary one.

We have professional engineers team to draw flowchart based on customer's gold mine site details.

We supplied full set gold plant: vibrating feeder, jaw crusehr, hammer crusehr, gold centrifugal concentrator, wet pan mill,

sluice box and shaking table.

We supplied full set gold plant: vibrating feeder, jaw crusehr, hammer crusehr, gold centrifugal concentrator, wet pan mill,

sluice box and shaking table.

Successful Cases

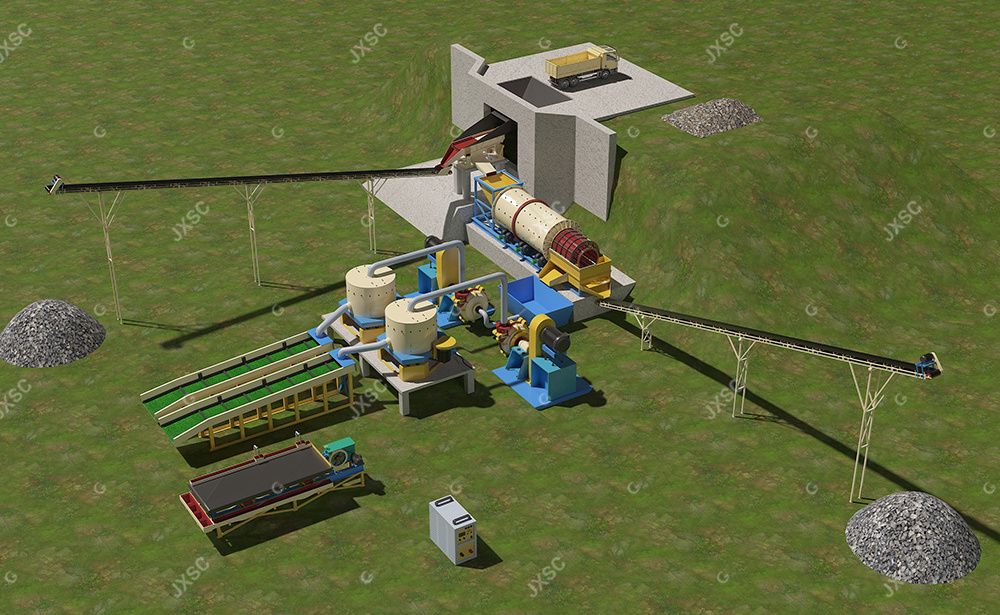

200TPH Clay Alluvial Gold Washing Plant in Ghana

complete set 200TPH washing plant including below configurations:

complete set 200TPH washing plant including below configurations:

1. Feeding hopper

2. Vibration Feeder with grizzly

3. Drum scrubber

4. High Frequency Vibration Screen

5. Sluice Box

6. Belt conveyor

7. Gold centrifugal Concentrator

8. Shaking table

9.Accessores : water pump, high pressure water gun, diesel generator, electric control pannel, cables &wires, water pipes,

connection chutes , Corridor fence, high steel frame.

connection chutes , Corridor fence, high steel frame.

This Plant can catch all sizes of gold concentrate from 0-20mm, high recovery ratio reach 75-80%, low power consumption, Easy operation and maintance, Smaller Investment comparing with other solution, low operating costs. We can Customize the Most suitable Solutions according to your gold ore conditions and requirements for the plant. Welcome to contact us for more details.

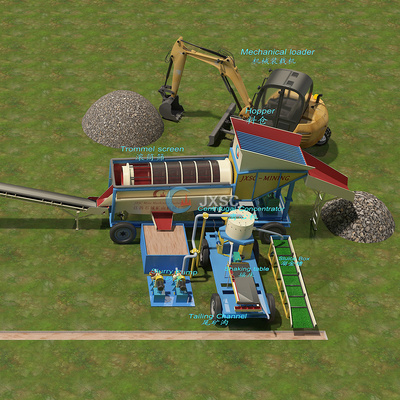

40T/H Capacity Complete set Mobile alluvial gold processing plant for Korea

complete set mobile gold washing plant for our Korea customer's alluvial gold recovery project. The machines include: gold washing trommel scrubber, gold centrifugal concentrator, shaking table and sluice box. All the machines are mobile with wheel, very easy to move and operate, high recovery effect.

This set machine processing capacity is 40T/H, suitable for washing alluvial gold with sticky clay. Detail machine as below:

1.Mobile gold washing trommel scrubber: Diamter: 900mm, length of screen:1.5m, length of scrubber:2.5m, two layers screen. with big grizzly hopper, water pump, with water pipes around the hopper, with water pipe insider&outside of trommel screen, mobile with wheels.

2. Mobile gold centrifugal concentrator: Model STLB60, mobile with wheels.

3. Mobile LY Shaking table ,mobile with wheels.

4. Sluice box: 6m*1m*0.3m(L*W*H), with cover on top.

4. Sluice box: 6m*1m*0.3m(L*W*H), with cover on top.

Other Successful Cases

Packing and Delivery

◆ Ways of packing

1. Small parts packed in the wooden cases

2. Big parts packed by plastic membrane

3. The whole big machine is loaded in the container

◆ Shiping by sea/air freight

any way the customer requires.

Hot Searches