NaN / 0

Pet Food Machine for Dog Dry Food Processing Equipment Cat Food Production Line

Get Latest Price

US$ 8000

≥1 Sets

Quick Details

Marketing Type:

Hot Product 2023

Place of Origin:

Shandong, China

Brand Name:

Joyang

Voltage:

380V(Customized)

Product Details

Pet Food Machine for Dog Dry Food Processing Equipment Cat Food Production Line

Product Description

Raw material of our pet food making machine

Pet Food Processing Line can use meat meal, fish meal, corn powder, soya meal and other grains powder as raw materials to produce dry pet food, such as dog, cat, fish, bird food etc. You can also use meat, bone, animal viscera, fish, vegetable, fruit, etc to produce pet food.

Samples of final pet food

Our pet food extruder machine can adjust the moulds, temperature, formula, etc to produce different shapes and tastes of dry pet food.

Pet food process line flow chart

Mixer---Screw conveyor---Pet food extruder---Air conveyor---Drying machine---Hoister---Flavor drum---Cooling conveyor

Why choose to produce extruded pet food?

1. Improve the digestion and absorption of pet food.

2. The extruded pet food are produced under high temperature condition , so it can kill all kinds of microorganisms, eggs and pathogenic bacteria in the pet food, improve the quality of the pet food, and reduce the digestive tract diseases of pet.

How to custom pet food production line?

1. Tell us your target capacity

We can provide different capacities pet food process line, like 140-160kg/h, 240-260kg/h, 400-500kg/h, 800-1000kg/h, 1-1.5T/h, 1.5-2T/h, etc.

2. Tell us the energy available in your workshop

We can provide the different energy of pet food drying equipment, like electric dryer, gas dryer, diesel dryer, steam dryer.

3. Tell us the industrial voltage in your workshop

Our pet food production line need both 3 phase voltage and single phase for. Please confirm it with your electrical engineer . For example, the industrial voltage in China is 3 phase 380V 50Hz and single phase 220V 50Hz.

4. We can also provide the material processing machines ( like garins grinding machine, bone broker, meat grinder, colloid mill, etc) and packing machine .

Technical Parameters of pet food process line

| Model | JY-65 | JY-70 | JY-85 | JY-95 |

| Installed Power | 76kw | 95kw | 178kw | 256kw |

| Power Consumption | 54kw | 66kw | 125kw | 195kw |

| Production Capacity | 140-160kg/h | 240-260kg/h | 500kg/h | 800-1000kg/h |

| Dimension | 17x2x2.5m | 22x2x2.5m | 26x2x3.5m |

42x2.8x4.0m |

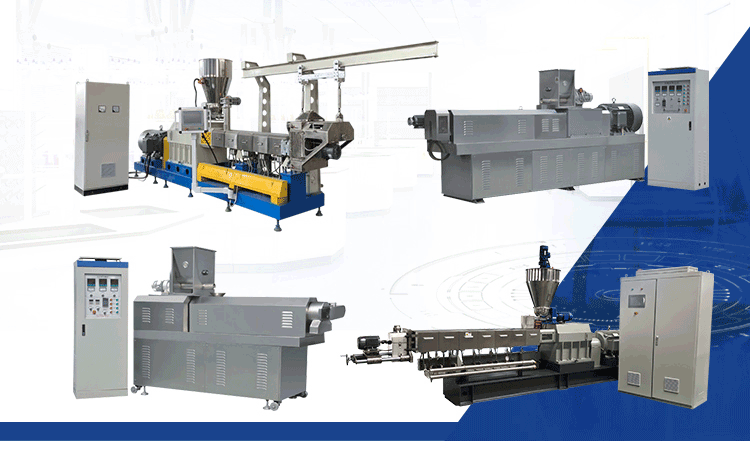

Detailed Images

Raw materials batching system and Packing Machine

Hot Searches