NaN / 0

Full Automatic Aerated Autoclave Concrete Aac Block Making Machine Equipment Production Line Manufacturing ALC panel plant

Get Latest Price

US$ 10000

≥1 Sets

US$ 4000

≥5 Sets

Quick Details

Type:

Autoclaved aerated concrete block (AAC)

Brick Raw Material:

Cement

Production Capacity (Pieces/8 hours):

Other, 4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours, 3600-6500pcs/8h

Brick size:

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

Product Details

Product Description

Product Description

HONGFA AAC Plant Introduction

Hongfa factory with 80 production line plant abroad AAC (Autoclaved aerated concrete) block Main raw materials of AAC are siliceous material (sand, fly ash and Silicon tailings) and Calcium materials (lime and cement) mixed with foaming agent (aluminum powder). Autoclaved aerated concrete machine Autoclaved aerated concrete block machine Cement Fly Ash Lime aac block making machinery

It is the product of light porous silicate through the following processes: batching, mixing, pouring, hardening, cutting,

autoclaving and curing etc. Because of large amount of well-distributed tiny pores after foaming, it is named autoclaved aerated concrete. AAC Classification: In general, it can be classified according to the types of raw materials, manufacture process and functions.

autoclaving and curing etc. Because of large amount of well-distributed tiny pores after foaming, it is named autoclaved aerated concrete. AAC Classification: In general, it can be classified according to the types of raw materials, manufacture process and functions.

Based on the shape of AAC products, it can be divided into: AAC blocks and AAC panels. It is a revolutionary material offering an unique combination of high durability and strength, low weight, excellent heat insulation, fire resistant, noise absorption, unprecedented build ability and superior ecological green features. In China, AAC is one of the light wall materials which was popularized and applied at the earliest and the most widely.

AAC Block Introduction

AAC Block Introduction

AAC block raw material

AAC block raw material required performance:

Fly ash: A lot has been said about this raw material in this Project Profile itself. But this Raw material is freely available in

Thermal Power plants. There are no taxes on this item whatsoever. Transportation charges are only to be attended by the

entrepreneur.

Sand (65-70%): The core raw material of AAC product; the main resource of silica-aluminum components; correspond with JC409-91, the clay should less than 4%.

Fly ash: A lot has been said about this raw material in this Project Profile itself. But this Raw material is freely available in

Thermal Power plants. There are no taxes on this item whatsoever. Transportation charges are only to be attended by the

entrepreneur.

Sand (65-70%): The core raw material of AAC product; the main resource of silica-aluminum components; correspond with JC409-91, the clay should less than 4%.

Lime(12-20%): One of the main raw materials of fly ash AAC; the main effect is to provide efficient calcium oxide with cooperation of cement making calcium oxide react with SiO2, Al2O3 in hot water then to produce calcium silicate hydrate. Therefore, lime is also the main resource of strength. Effective calcium oxide of lime should not less than 65%, over 80% is perfect and should accord with JC/T621-1996.

Cement(8-10%): This Project aims to utilize OPC cement as main binder material. It will give faster strength to the bricks,

besides giving improved consistent quality. It also ensures a better cost effectiveness for the same. Using OPC will be a

standardized practice. The other prime advantages of using OPC (compared to other binders) is it’s easy availability locally

through nationwide Retail Network of Cement Companies.

Gypsum(1-2%): Gypsum is the foaming regulator in AAC which dispels quicklime and postpones slurry’s densification.CaSO4 should be more than 70%.

Aluminum Podwer(0.074%): It is the forming agent type and recommendation for supply depend on raw materials and mix formula:A lot has been said about this raw material in this Project Profile itself. But this Raw material is freely available in Thermal Power plants. There are no taxes on this item whatsoever. Transportation charges are only to be attended by the entrepreneur.

Cement(8-10%): This Project aims to utilize OPC cement as main binder material. It will give faster strength to the bricks,

besides giving improved consistent quality. It also ensures a better cost effectiveness for the same. Using OPC will be a

standardized practice. The other prime advantages of using OPC (compared to other binders) is it’s easy availability locally

through nationwide Retail Network of Cement Companies.

Gypsum(1-2%): Gypsum is the foaming regulator in AAC which dispels quicklime and postpones slurry’s densification.CaSO4 should be more than 70%.

Aluminum Podwer(0.074%): It is the forming agent type and recommendation for supply depend on raw materials and mix formula:A lot has been said about this raw material in this Project Profile itself. But this Raw material is freely available in Thermal Power plants. There are no taxes on this item whatsoever. Transportation charges are only to be attended by the entrepreneur.

Manufacturing Technique

Manufacturing Technique

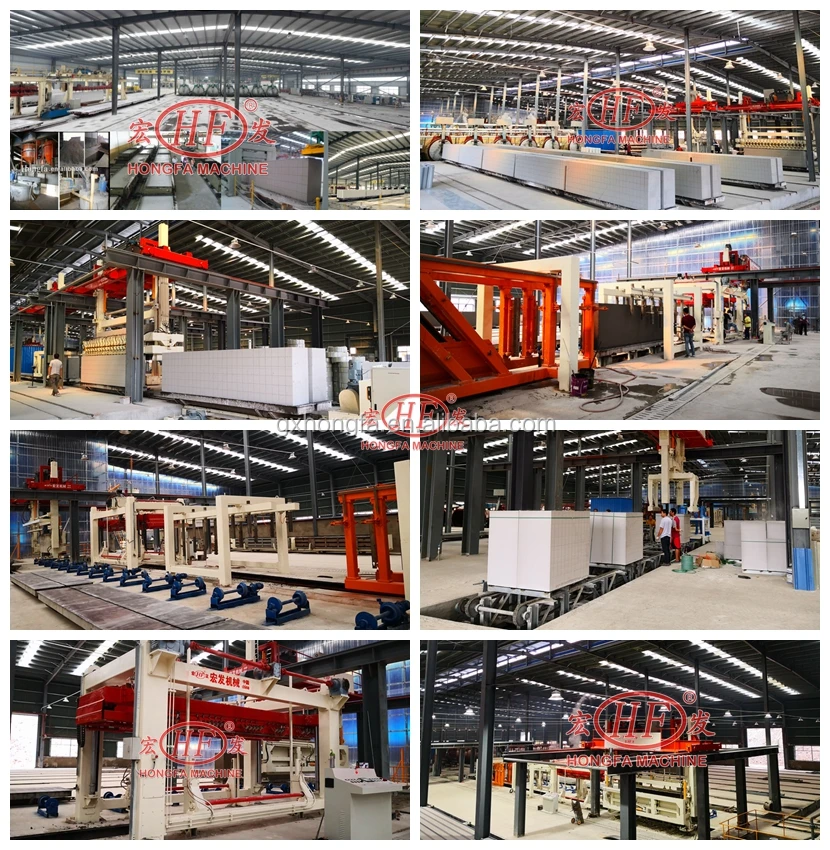

Raw material dealing

Put the fly ash or sand into the ball mill to mill via the conveyor belt, after milling, put the slurry into the slurry storage

tank by slurry pump.

tank by slurry pump.

Batching, mixing and pouring process

The lime, cement will convey by conveyor to the dry powder measure scale to scale separately. The slurry convey by slurry pump then to the automatic scale;the power and slurry put into the mixer,pouring into the mould.

Curing process

After slurry pouring into the mould, put the mould box into the curing room with 50~70℃. After 2-3 hours curing, the blocks become soft solid and ready for cutting.

Cutting process

Cutting size can be adjusted flexibly, with 0 broken rate.

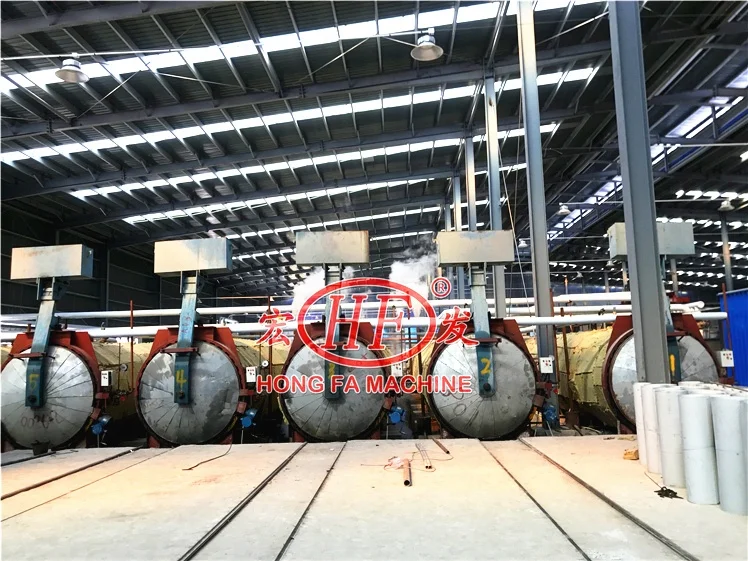

Aerated autoclaved process

Finished cutting using semi-product crane carry to the front of autoclave grouped, hoisting machine or dragger will drag steam trolley into autoclave to steam,it need 6-10 hours.

Finished block dealing process

After 6-10 hours, finished products come out of autoclave, with separting machine to separate blocks layer by layer.

Packing process

Using finished block carry hanger clamp the finished product to package line on wooden pallets,after package, then by forklift transport the finished products to piled yard according to specifications to stack.

Packing&Shipping

Packing&Shipping

Company Introduction

Company Introduction

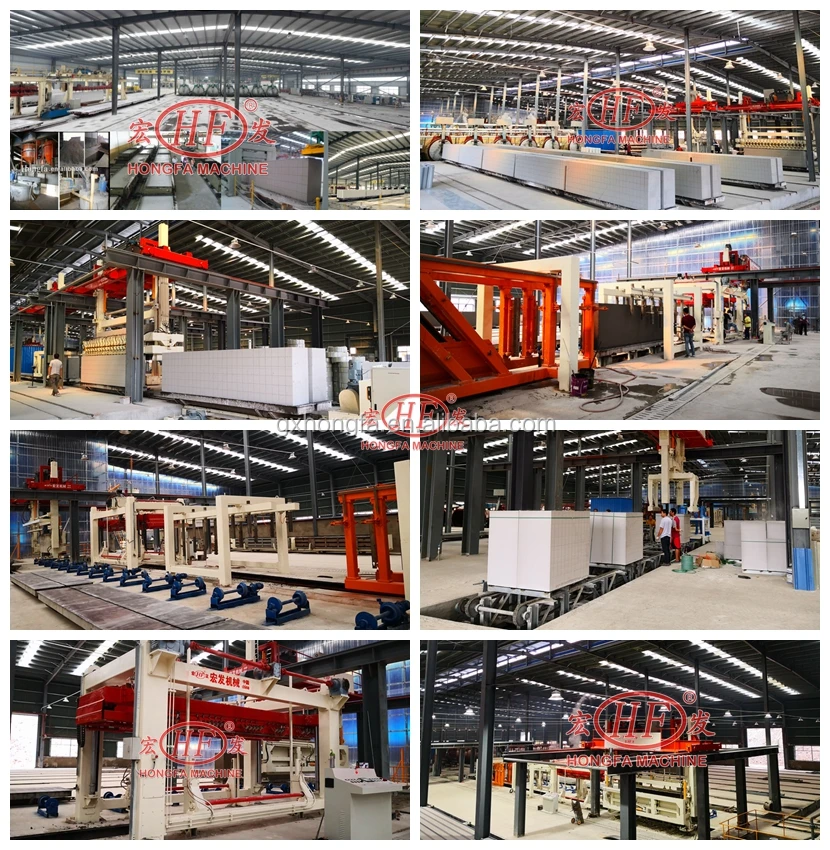

HONGFA is a construction and building materials equipments manufacturer mainly produce all kinds of AAC block making

machine,concrete mixing plant,mixer,Concrete Block Shaping Machine,concrete tile making machine and concrete pipe making machine etc. With more than 30 years experience and being the biggest manufacturer in China at present.All the products are conformity with the standard of the state, and gets the ISO9001-2000 Quality System certificate, also honored as "One of the Top Ten Famous Brands of Brick &Tile field in China" and other honors.

Hongfa Machinery's Honor

1.One of Top Ten Influential Brands in China Brick &Tile Industry

2.China National Enterprise Abiding By Contract & Keeping Good Faith

3.Quality and Credibility of the Dual-protection Demonstration Unit

4.High and New Technology Enterprise

5.Famous Trademark of China

6.Star Enterprise with China Patent

7.AAA Grade Credit Enterprise

8.Consumer Satisfaction Unit

9.One of Top 100 building Material Industry Brands of China

10.One of Top Ten Good Faith Units

11.Advanced Exporter in Guangxi Province

12.Advance Quality Management Unit

machine,concrete mixing plant,mixer,Concrete Block Shaping Machine,concrete tile making machine and concrete pipe making machine etc. With more than 30 years experience and being the biggest manufacturer in China at present.All the products are conformity with the standard of the state, and gets the ISO9001-2000 Quality System certificate, also honored as "One of the Top Ten Famous Brands of Brick &Tile field in China" and other honors.

Hongfa Machinery's Honor

1.One of Top Ten Influential Brands in China Brick &Tile Industry

2.China National Enterprise Abiding By Contract & Keeping Good Faith

3.Quality and Credibility of the Dual-protection Demonstration Unit

4.High and New Technology Enterprise

5.Famous Trademark of China

6.Star Enterprise with China Patent

7.AAA Grade Credit Enterprise

8.Consumer Satisfaction Unit

9.One of Top 100 building Material Industry Brands of China

10.One of Top Ten Good Faith Units

11.Advanced Exporter in Guangxi Province

12.Advance Quality Management Unit

We we offer

*Pre-sales service

We can design the layout before you make workshop to help you get best suit work place.

*After-sales service

We gurantee 5 years after sales service and offer 1 set of spare parts when shipping, life span free technical maintenance

guidance.

*After-sales service

We gurantee 5 years after sales service and offer 1 set of spare parts when shipping, life span free technical maintenance

guidance.

FAQ

FAQ

1. Can this machine make my brick or other size block?

We would design and do the mould according to customer's Drawing.

2. Are your company is the manufacture or trading company?

We would design and do the mould according to customer's Drawing.

2. Are your company is the manufacture or trading company?

We are Direct factory,not agent or trading company,and the quality and after-sale services is quaranteed.

3.How can I trust the machines quality?

Our products passed ISO9001-2000 and CE identifications, we started produce different types of concrete block machines for 30 years since 1990, with rich industry experience, we are always keeping technics updating. Furthermore our machines have been exported to more than 96 countries and always have a good reputaion from our oversea customers. We test all the machines before shipping, make sure every machine works well when they delivered.

4. When do you delivery the goods?

Normally 30 days after receipt of deposit and moulds confirmation from Buyer.

5. What about the payment terms?

30% as down deposit by T/T ,70% as the balance paid by T/T before loading(L/C is also acceptable).

6. Would you mind provide the video?

The video is available to send to you, please contact me.

7. How about the commissioning of the machine and training to workers?

Yes, after finish the installation of the block production line, our engineer will do the testing and commissioning, and make the most suitable ratio of the materials to make the blocks, and train the workers how to operate and maintain the machines. Aac Foam Machine Concrete Lightweight Aac Block Making Machine Solid Small autoclaved araeted concrete Making Block Machine High Quality Aerated Concrete Aac Block Making Machine Production Line autoclaved aac panel Cutting machine lightweight concrete panel machines autoclaved aerated concrete wall panels autoclaved aerated concrete machine Automatic Brick Manufacturer's Plant Production Line Light Foam Concrete Gas Block Machine Aac Aerated Concrete Equipment Autoclave Full Automatic Aerated Autoclave Concrete Aac Block Making Machine

Our products passed ISO9001-2000 and CE identifications, we started produce different types of concrete block machines for 30 years since 1990, with rich industry experience, we are always keeping technics updating. Furthermore our machines have been exported to more than 96 countries and always have a good reputaion from our oversea customers. We test all the machines before shipping, make sure every machine works well when they delivered.

4. When do you delivery the goods?

Normally 30 days after receipt of deposit and moulds confirmation from Buyer.

5. What about the payment terms?

30% as down deposit by T/T ,70% as the balance paid by T/T before loading(L/C is also acceptable).

6. Would you mind provide the video?

The video is available to send to you, please contact me.

7. How about the commissioning of the machine and training to workers?

Yes, after finish the installation of the block production line, our engineer will do the testing and commissioning, and make the most suitable ratio of the materials to make the blocks, and train the workers how to operate and maintain the machines. Aac Foam Machine Concrete Lightweight Aac Block Making Machine Solid Small autoclaved araeted concrete Making Block Machine High Quality Aerated Concrete Aac Block Making Machine Production Line autoclaved aac panel Cutting machine lightweight concrete panel machines autoclaved aerated concrete wall panels autoclaved aerated concrete machine Automatic Brick Manufacturer's Plant Production Line Light Foam Concrete Gas Block Machine Aac Aerated Concrete Equipment Autoclave Full Automatic Aerated Autoclave Concrete Aac Block Making Machine

Hot Searches