NaN / 0

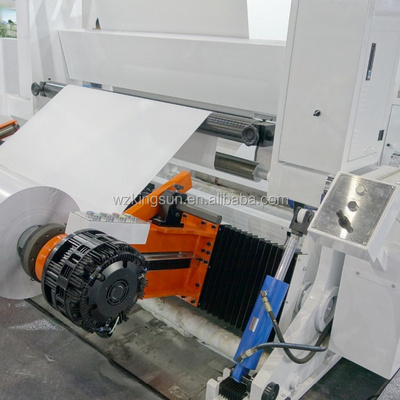

KSFQ-G High Speed Automatic Jumbo Roll Self Adhesive Paper Slitting Machine

Get Latest Price

US$ 48000

≥1 Sets

Quick Details

Type:

Slitting Rewinder

Production Capacity:

400m/min

Place of Origin:

China

Max slitting speed:

400m/min

Product Details

KSFQ-G series high speed automatic jumbo roll self adhesive paper slitting rewinding machine

This series high speed paper slitting machine was developed with our 25 years manufacturing experience and adopts Europe technology,i t is an ideal converting equipment for jumbo roll paper to slit into required size rolls. High quality with very competitive price. If you are looking for high grade slitting machine, this is for sure one of your best choice.

Main features:

1) The newest technology from German and Japan were adopted in the slitting machine

2) Most reliable international famous brand components adopt for this slitter machine

3) Touch screen HMI,easy for operation and maintenance.

4) High speed,heavy duty and high precision slitting rewinding system design.

5) Whole machine life technical support, spare parts and any other services.

Product Description

Main technical specifications:

|

Maximum unwinding diameter |

φ1200mm |

|

Maximum rewinding diameter |

φ600mm |

|

Maximum web width |

1300mm |

|

Min slitting width |

50mm |

|

Rewinding paper core diameter |

3″ |

|

Unwinding paper core diameter |

3/6″ |

|

Maximum machine speed |

400m/min |

|

EPC precision |

≤0.40mm |

|

Unwinding motor power |

Pneumatic brake (2 sets) |

|

Rewinding motor power |

3.5KW ( 2 sets) |

|

Driven motor power |

5.5KW |

|

Total power of machine |

25KW |

|

Machine out dimensions |

4100 (L) x 4700 (W) x 2100mm (H) |

|

Machine Weight |

About 4200kg |

|

Applicable materials |

Paper, Adhesive paper |

|

Machine color |

Milk white (other colors can choose) |

Main parts configurations:

|

PLC controller |

Simens |

|

Man-machine interface |

Taiwan weinview |

|

Frequency converter |

Japan Yaskawa |

|

EPC controller |

Guangzhou |

|

Web guide DC motor |

NEC, Japan |

|

Main motor |

Simens |

|

Rewinding motor |

Simens |

|

Main Pneumatic components |

AirTAC |

|

Electric Proportional valve |

Japan SMC |

|

Precision pressure regulator value |

Japan SMC |

|

Ultrasonic sensor |

German P+F |

|

Main Bearings |

NSK, Japan |

|

Main low voltage electric |

France Schneider |

Machine sketch drawing:

Packaging & Shipping

Hot Searches