NaN / 0

Manufacturer Gravel Washing Plant Machine Price Equipment Sand Gravel Washer Sand Washing Machine

Get Latest Price

US$ 6000

≥1 Sets

US$ 5700

≥2 Sets

Quick Details

Capacity(t/h):

50-850 t/h

Place of Origin:

Shanghai, China

Brand Name:

SBM

Dimension(L*W*H):

4500x3206x3480

Product Details

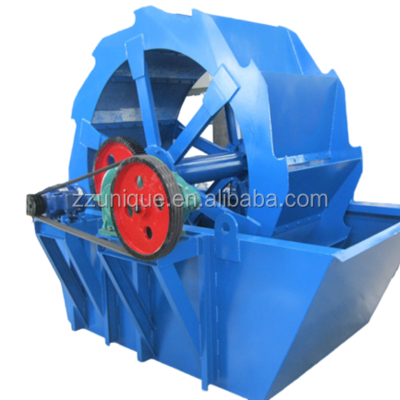

gravel washing plant machine price equipment sand gravel washer sand washing machine

Product Description

hi ,welcome.if you interested in gravel washing plant machine price equipment sand gravel washer sand washing machine , Welcome to visit our factory in Shanghai, China!

> Product Picture

XSD Sand Washer

XSD Sand Washer is commonly known as wheel-bucket type sand washer. It is developed and produced by SBM through adopting domestic and overseas advanced technologies and combining the actual situation of domestic aggregate industry. It is usually used with the sand maker.

Product Features: Simple structure, low failure rate, big capacity and high cleanliness

Input Size: 0-10mm

Capacity: 20-120TPH

Material: Granite, marble, basalt, limestone, quartz, pebble, copper ore, iron ore and so on

gravel washing plant machine price equipment sand gravel washer sand washing machine advantages

Large Capacity & Low Production Cost

The capacity of a XSD Sand Washer can reach 180t/h, which satisfies most sand washing requirements. The sand-washer is of small investment and low power consumption. So the production cost can be saved a lot.

Simple Structure & Low Failure Rate

The XSD Sand Washer is of simple and reasonable structure. The impeller drive bearing device is separated from the water and materials exposed to water. The new sealing structure and totally enclosed oil bath-type transmission device greatly avoid the occurrence of bearing damages caused by water soaking, sand and pollutants.

Multiple Functions---Washing, Dewatering And Grading

The XSD Sand Washer possesses washing, dewatering and grading functions. When working, the aggregate will grind mutually under the driving of impeller to remove the sundries covering on the aggregate surfaces and destroy the water vapor layer covering the sand. The XSD Sand Washer can also complete the washing and purifying functions under the effect of strong water flow.

Long Service Life & No Pollution

XSD Sand Maker has good structural layout and effective sealing design, allowing it to operate for a long term without maintenance (i.e., it is durable.). The water consumption is low and the operating noise is small which meet the national environmental protection standards.

gravel washing plant machine price equipment sand gravel washer sand washing machine work principle

When gravel washing plant machine price equipment sand gravel washer sand washing machine worked, the motor drive the impeller slow rotation through the V-belt, reducer, gear reducer, sand and gravel are carried into the washed tank trough the feeder tank, tumbling by the impeller, grinding each other to remove the impurities which cover on the gravel surface, while destroying the vapor-coated layer of sand to facilitate dehydration; as the same time, add water to create a strong water flow to remove impurities in time, and issue from the export of washing tank, so that to complete the cleaning effect. Clean sand and gravel away from the blade, at the end the gravel was poured from the rotation of impeller to the exit of tank, so complete the gravel cleaning effect.

| Model | Feeding Size(mm) | Capacity(t/h) | Power(kw) |

| XSD2610 | ≤10 | 20-60 | 8-7.5 |

| XSD3016 | ≤10 | 70-120 | 8-15 |

gravel washing plant machine price equipment sand gravel washer sand washing machine technical data

Click for More Information!!!

Customer case

river pebble sand production line

1 Background

The production line main equipment provided by SBM Industrial Technology Group, which is the local largest peripheral mechanism sand production scale, the effect and the profitable production line, now the production line capacity is fine mechanism sand 150-250 tons per hour. Product application: supply high-speed rail, Gezhouba Hydropower Station.

2 Equipment configuration

| Equipment configuration |

| jaw crusher PEW760 |

| hydraulic cone crusher HST250 |

| VSI5X-1145 impact crusher |

| Vibrating screen |

| Vibrating feeder |

| sand washerXSD3016 |

3 Process flow

Pebble material goes into European hydraulic jaw crusher PEW760 for coarse crushing, and get into single cylinder hydraulic cone crusher HST250 for second crushing through belt conveyor, and then enter into control bunker, in addition to begain sand making less than 40mm with impact crusher VSI5X-1145 via belt conveyor, finallly fine sand product size is 0-5mm, now the quality and price is fully comparable to the high quality natural river sand.

4 Equipment configuration advantage

a. European hydraulic jaw crusher: jaw assembly with high quality steel castings, heavy eccentric shaft by forging blank processing, which make machine has excellent reliability, more durable, besides, equipment is provided with a wedge discharge opening adjusting device,which is more simple, safe and fast than the traditional gasket adjustment. The crushing chamber adopts symmetrical "V" shaped structure, which makes actual feed inlet width inlet is in line with nominal feed inlet width.

b. Single cylinder hydraulic cone crusher: high production efficiency and strong bearing capacity, low operation cost and maintenance. Automatic control of production process, multi cavity adapt to a variety of process requirements.

c. Hydraulic centrifugal impact crusher: impact crusher is arranged on the top of the hydraulic lifting device for maintenance. Impact crusher with thin oil lubrication station equipment don not need to manually refuel per shift and reduce labor costs. Impact crusher using intelligent touch screen control display can observe equipment working process in real time. Impact crusher has low production and high efficiency cost, and then large capacity, furthermore, the mechanism sand is quality , which can replace natural river sand, moreover, the production line has been free to change gravel and shape function according to needs.

Click for More Information!!!

> Customer Site

Click for More Information!!!

Customer feedback

Welcome to visit our factory

See what other customers say

- “ We haven’t replaced any spare part after continuous running for 16 months . Everything is still in perfect condition so far !”-- Mrs. Camille Camille,concrete crushing plant

- "Our local stones market is good , so I value the stability of the equipment operation. The quality of the equipment is good , and maintenance operation is convenient, basically do not need the company here to send technicians, we follow the manual can complete. The output is also fully achieved, the profit is good, a few of my colleagues visited here after I also ordered the world state equipment. " -- Mr. Chen, the sand production line

-

"

I am pleased with the company's design process and the wiring, many of the nearby counterparts to watch the production line.

Equipment quality is also satisfactory, the company's service is good

, we can not meet the problem, will soon be able to send engineers over guidance. Within the original plan to recover the cost within two years, it seems that about a year now is enough. " --

Mr.Fernanda Luisa, the mobile stone production line

-

"

SBM help me build the crushing production line

,

equipment selection is more advanced, scientific and reasonable, high intelligent control, more peace of mind. So far, the daily profit of nearly 100000 yuan, I am very satisfied.

"

--

Mr. Susan James , the limestone grinding plant

Certifications

Cooperators

Hot Searches