NaN / 0

Sand Washing Plant, Sand Washing Equipment, Screw Silica Sand Washing Machine Price Manufacturing Plant

Get Latest Price

US$ 5000

≥1 Sets

Quick Details

Place of Origin:

Henan, China

Brand Name:

FTL

Voltage:

380V/ 220V

Power:

according to capacity

Product Details

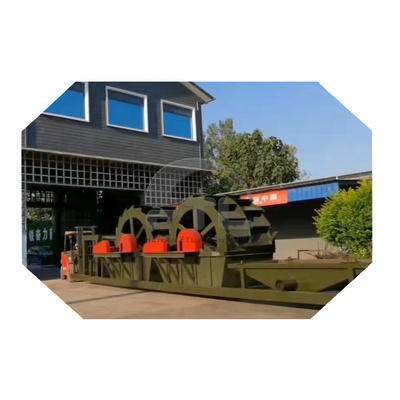

Sand Washing Plant, Sand Washing Equipment, Screw Silica Sand Washing Machine Price Manufacturing Plant

Product Description

Sand washer is widely used for the washing of the material sand quarry, mining, building materials, transportation, chemical industry, water conservancy and hydropower, concrete mixing station,etc.

According to different kind of washing type, we have:

1. wheel type Sand washing machine is a multi-function sand washing equipment that combines the washing, dewatering and recycling. The high output can reach more than 300 tons per hour, and continuous operation can be realized. In addition, slurry pump and cyclone are connected together to form the reflux of water, saving water consumption, screening and washing better, and promoting the development of the screening and washing industry.

Working Principle

Sand becomes the qualified products by the screening machinery, then flow into spiral stirrer through chute, the spiral stirrer will clean, soak, break up sand (especially directly at high mud content material), tailing waste discharges into separating device to concentrate and grading. Tailing and coarse ore discharges into dewatering screen to be screened and dehydrated at the same time, waste water discharges into separator by slurry pump to concentrate and grading. Then the finished product will be transported into material pile by belt conveyor and for sale.

2. Sprial sand washing machine can be used to clean sand, gravel, or for grading equipment. It is widely used in cleaning the materials containing a large quantity of mud obvious. It's a good seal structure, fully enclosed gear, efficient, durable, good dehydration effect, the power consumption is small, fine products remain stable.

Its seal structure, the use of closed transmission device, has high efficiency, durable, dehydration effect is good, small power consumption, and fine particle characteristics of products remain stable.

clink for combine sand washing, dewatering and reclycing machine

advantages

wheel type Sand washing machine:

1. Combine spiral, separator in one machine.

2. Efficient, energy saving, environmental protection.

3. Can be customized for different models.

4. Installation is simple, low maintenance costs.

5. Finished sand moisture content of less than 15%, mud content of less than 2%.

Sprial sand washing machine:

1. High capacity

2. Heavy duty conveying paddles

3. Fabricated with heavy duty tubs

4. Oversize bearings and gears

5. Thick-walled shafts

6. Lower end bolted to fully machined stub shaft. Upper end mounted through flexible coupling to output shaft of gearbox

7. The compound drive divides the operating load over an optimal combination of oversized helical and spur gears

Continuous grinding and abrading log washer paddles

8. Adjustable water discharge gates on both sides of lower end of the tub

Main specification

Wheel Sand Washing machine:

| Model | Diameter of the wheel bucket (mm) | Speed of Rotor (r/min) | Feed opening size (mm) | Production Capacity (t/h) | Motor Power (kw) | Overall Dimensions (mm) | Weight (kg) |

| XS2600(Ⅰ) | 2600 | 2.5 | ≤10 | 20-50 | 5.5 | 3515*2070*2672 | 2500 |

| XS2600(Ⅱ) | 2600 | 2.5 | ≤10 | 30-70 | 5.5 | 3515*2270*2672 | 2900 |

| XS2800 | 2800 | 1.2 | ≤10 | 50-100 | 7.5 | 3900*3300*2990 | 3980 |

| XS3200 | 3200 | 1 | ≤10 | 80-120 | 11 | 3965*4440*3410 | 7270 |

| XS3600 | 3600 | 1 | ≤10 | 120-180 | 15 | 4355*4505*3810 | 9430 |

Spiral Sand Washing Machine:

| Model | XL508 | XL610 | XL762 | XL915 | 2XL915 |

| Spiral Dia (mm) | 508 | 610 | 762 | 915 | 915 |

| Sink Length (mm) | 6705 | 7225 | 7620 | 7585 | 7585 |

| Feeding Size (mm) | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

| Capacity (t/h) | 20 | 40-50 | 50-75 | 100 | 200 |

| Spiral Speed (r/min) | 38 | 32 | 26 | 21 | 21 |

| Motor Power (kw) | 5.5 | 7.5 | 11 | 11 | 2*11 |

| Water Consumption (t/h) | 6-60 | 6-63 | 9-63 | 10-80 | 20-160 |

| Dimension (mm) | 8000*2343*1430 | 8000*2050*1400 | 8545*2650*3862 | 8500*2810*3600 | 8420*3765*3960 |

| Weight (t) | 2.67 | 3.80 | 5.23 | 6.27 | 11.11 |

Our projects

contact us

Hot Searches