NaN / 0

Oily sludge handling capability 55-112 84-150 kg/h QTBH-1000 Dehydrating Belt Press

Get Latest Price

US$ 5000

≥1 Pieces

US$ 3500

≥10 Pieces

US$ 2500

≥20 Pieces

Quick Details

Place of Origin:

Tianjin, China

Brand Name:

HatChee

Material:

Steel, Stainless Steel/Carbon Steel

Weight:

30kg

Product Details

Product Description

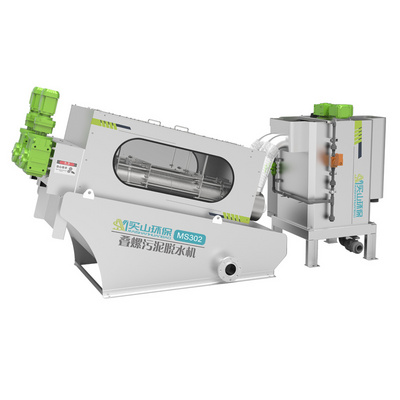

Screw Press

Description

The Screw Press introduced a new solution for sludge treatment with a new cutting-edge technology, streamline and automatic programmed design to make the operation much more convenient and accurate while provide a simple process, low system investment, high efficiency as well as energy -saving.

Our multi plate screw press is more advanced than traditional dewatering systems which can be easily blocked by low concentrated sludge. The Ecologix screw press allows for automatic continuous sludge flocculation, thickening, dewatering and filtrate discharging. The thickening zone allows the system to process both highly concentrated sludge as well as sludge with a high water content.

The core structure of the screw press is consisted of multiple layers of Fixed and Moving ring made by stainless steel sUS304 which secured in place by a tie rod while the inner diameters of the moving rings are relatively smaller than the outer diameter of screw and Fixed rings.

The traditional sludge treatment required a lots of pre-treatment process before the dewatering of sludge begin With the dewatering process can now be processed a low concentrated sludge from Oxidation ditch (aeration tank which provide the advantages in removing odor from sludge, reduce investment cost for Thickener tank and other related equipment as well as help in stabilizing the amount of phosphorus return into oxidation ditch which further implement a stable dewatering process.

Features

Exclusive pre-thickening enables a wide solid concentration ranging from 10,000mg/l to 50,000 mg/l

High efficiency with a small footprint

Low power consumption (less than 5% of a centrifuge)

Very low water usage (less than 1% of an equivalent belt filter press)

Auto start-up, run and shutdown

Self cleaning

No blocking or backwash water

Double nozzles for superior cleaning and rinsing

Able to handle oily sludge as well as fibrous sludge

Sealed system = No odors/bad smell

Wear free

Sludge flow and cake monitoring system

Exclusive screw shaft for sludge thickening and inorganic material

Multi Plate Screw Press Sludge Dewatering System

Components

304 SS Screw, Shaft, Collection Basin, Flocculation Tank, Main Body

Sludge thickening & dewatering zone

Sludge flocculation tank

Filtrate collection tank

Automatic / Automated control panel

Fixed plates and moving plates instead of filter cloth

How It Works

The conditioned sludge flows into the filter chamber from the flocculation tank and is pushed to the discharging end. The thread on the shaft gets progessively tighter as the wasterwater flows through the system, this causes the pressure on the sludge to increase. The water is then separated from the sludge. The movement of the moving and fixed rings cleans the gaps between them and prevents blockage traditionally experienced in similar systems. The filtered sludge cakes are pushed forward by the shaft and finally discharged from the end.

Working Principle

The dewatering process begin at the initial section called Thickening zone, when the screw shaft rotating and separating liquid from solid sludge by the gaps between the multi-disc rings, the filtrated will then be discharge at the bottom drain hole while sludge will moving on to Dewatering zone where the pitch of the screw and the gaps between the multi-rings decrease at the end of drum thus increasing internal pressure at the end plate to discharge dry sludge cake.

The structure of Fixed and moving rings provided a clog-free feature in which the moving rings are mobilizing by the screw and continuously cleans the sludge out of the gaps to prevent clogging.

Advantages

Widely used in many industries sludge treatment including municipal sewage, food, slaughtering breeding printing dyeing oil chemical, paper industry, leather; pharmaceutical, etc.

Oily sludge handling capability.

Ability to handling low concentration sludge from 2,000 mg/L up to50,000m g/L.

Rotating ring and automatic spray cleaning system provide selfcleaning ability during process and prevent clogging allowing a continue operation for 24 hour without user assist.

Control panel equipped with inverters and pic for automatic and manual function.

Wear free structure, long service life and utilizing a small footprint for installation.

Type description

Cost efficiency

With innovation and working principle of screw press allowing it to leverage a cost efficiency in energy consumption for wastewater treatment system, due to its low speed running(2-4 rpm) while operating, provide screw press to consume energy at low rate (average energy consumption at 0.1-0, 01 kwh/kg-DS.,low water consumption for cleaning as well as generate minimum noise.

By using multi-disc technology the sludge can be draw directly from aeration tank and secondary sedimentation tank without establishing a sludge thickeners process, thus, enhancing phosphorus removal effect in wastewater treatment system as well as deceasing a total investment cost as a whole.

Comparison Chart

SCREW PRESS

INTRODUCTION

During the water treatment process, it will produce different kinds of moistured sludge. The sludge dewatering System is mainly used for reducing water content, moisture rate and sludge volume. This will bring convenience for next sludge treating process. Generally, the sludge dewatering System can be divided into belt press, plate and frame filter press, screw press. Currently, belt press has been widely applied in sludge dewatering process. Due to its large water consumption, high requirements of handling problems, screw press is a new kind of sludge dewatering system with energy conservation stable and high automation.

WORKING PRINCIPLE

The main body of screw press consists of several fixed rings and movable rings. The screw shaft runs through these rings, finally forming a filter unit. The former stage is thickening Stage and the end is dewatering stage. Due its unique structure, it has replaced the traditional filter cloth and centrifugation.

FEATURES

• Simple treatment process, high efficiency of dewatering and thickening, low investment cost.

• Dosing with PAM agent for easy dewatering.

• High degree of automation, wide application.

• Continuous operation,no secondary pollution.

APPLICATION

It is widely used in municipal sewage, food, beverage, slaughter and breeding, printing and dyeing, petrochemical industry, paper making, leather, pharmaceutical and other industries.

STACKED SLUDGE DEWATERING

PRODUCT STRUCTURE

The main part of the dehydrator is a filter device that a screw runs through the stacked fixed rings and moving ring.

The small gaps between fixed rings and moving ring can filter the sludge, and the lumen between screw and rings filled with polymer grains. The moving ring transfers the sludge to the end of the machine with pressure and extrudes sludge cakes.

The running of the screw drives the moving ring to clean the gaps and avoid jam.

PRODUCT APPLICATION

City mixed raw sewage, Food and beverage industry, Chemical Industry, Stone & Mine Sewage, Leather & tannery sewage, Paper & pulp sewage, Electro -plating Sewage, Printing & dyeing sewage, Power plant, Petrochemical industry.

PRODUCT FEATURES

• Suitable for sludge treament of high /low consistency

• There is no need to worry about jam up. Reduce the cleaning water consupmtion.

• The electrical cabinet, disposal tank and dehydrator are integrated, reducing the covering area and brings convenience to installment.

• The dehydrator is enclosed working, reducing the bad smell and improving the working environment.

• Automatically working for 24 hours reducing the labor stength of workers.

• The slow running speed of srcew shaft reduces the power consumption and noise.

• It is made with stainless, extending the service life.

• It is convenient for daily maintenance.

DS Standard Capacity= Sludge flow*Sludge Consistency (DS refers to Dried Sludge).

In actual operation, the featuresof slurry, disposing approaches, running state andrunning time will affect the replacement cycle of the wearing parts. (the replacement period of wearing parts is calculated as 365 days/year, 8hours/day.)

1. The sludge is the sludge sump is carried to the measuring tank by sludge pump, and the sludge inlet volume can be controlled by adjusting the liquid level tube.

2. Sludge and flocculant will form alum floc in the disposal tank after agitator mixing, the ideal diameter of alum floc is about 5mm.

3. After gravity thickening in the thickening part, large amount of filtrate will discharge from thegaps between rings.

4. The thcikened sludge is carried forward by the screw dehydrated sufficiently under the pressure of the back pressure plate.

5. The dehydrated mud cake is discharged from the gaps between back pressure plates and screw body. The treating capacity of sludge and water content’s rate of mud cake can be controlled by adjusting the running speed of screw and gaps between back pressure plates.

ROTARY DRUM THICKENING

DEHYDRATING BELT PRESSES

QTA/QTAH SERIES

FEATURES

• Material of the main structure .

• Belt: imported from America and has a long service life.

• Low power consumption. slow- speed of revolution and low noise, the travel of noise is no more than 75dB (A).

• Adjusment of belt. pneumatic regulated, ensures the stability of the machine.

• Multi-point safety detection and emergency stop device: improve the safety of operation.

• The design of the system is obviously numanized and provides convenience in operaion and maintenance.

APPLIANCE

1. Sludge dewatering of various industrial wastewater.

2. Sludge dewatering of butchery, husbandry.

3. Slurry and water seperation in food & beverages industry, chemical industry, mining abd other industries.

4. Sludge dewatering of city sewage, excretion, water purifying materials.

QTB SERIES (Middle/High Consistency)

QTBH SERIES (Suitable for Low/Middle Consistency)

QTE SERIES

ROTARY DRUM TYPE THICKENING SYSTEM

The free water seperated from the sludge (which mixed and flocked with Polymer Solution). Suspended solid Consistency will be adjusted up to 4-9% and reach the function of sludge thickening and reduction.

The stable structure sludge after Rotary Drum Thickening wil be without side -leakage, increase the permeability of filter-cloth, the treating quantity and increase the water contents rate of sludge cake.

QLDN SERIES SCREW SLUDGE THICKENER

On the basis of screw sludge Dewatering Machine, We research and develop a new sludge thickening equipment.

ADVANTAGES

• Save the construction invesment and land occupation.

• Decrease the release of fetor and phosphor.

• Reduce the load of subsequent processing.

• Improve the capacity of sludge dewatering machine or deep dewatering equipment.

BELT FILTER TYPE THICKENERS

INTEGRATED SLUDGE DEEP DEWATERING SYSTEM

TECHNOLOGY INTRODUCTION

The technology of integrated sludge deep dewatering combines chemical and physical methods to modify the sludge character. In this processing, nanograde inorganic reagents is used to break adhesive sludge particles into crystal particles quickly, making the absorbed water on the surface of sludge particles and the inner bound water to be free water. The moisture content rate of sludge cake will be 60% or less after pressed under a high pressure of 1.0 to 5.0 MPa by a special stainless steel filter press gradually.

This kind of technology can reduce the moisture content rate from 90% to 60% or less, even can reduce thewater content rate of thickening sludge from 97% to 60% directly. The moisture content rate of sludge cake can be even reduced to 20% after natural air drying for 24 hours (in summer or good weather ) to 72 hours (in winter or wet weather).

The calorific value of the sludge cake is over 800—1200kcal after dehydration. It can be transported to power plants or garbage incineration power plant to generate electricity by burning with coal or household garbage (usually burning 4-5 tons of mud cake can save 1 ton of standard coal). It can also be used for landfill cover soil, then solve sludge secondary pollution thoroughly.

The sludge deep dewatering transfers the sludge to crystal stru cture and changes its microstructure, making the mud respiratory. Degradation of sludge changes from anaerobic process into aerobic process. The generation of odor is greatly reduced after the reaction of modifier with the odor source in sludge, such as hydrogen sulfide, mercaptans and other substances. Bacteria, parasite eggs and viruses in sludge died because of sludge respiratory, PH value, change of mud structures the coating of inorganic substance.

99% sludge dewatering water by weight than the original sludge decreased more than 70%, the volume is reduced by 60%.

SLUDGE SILO

FEATURES

• Customer design for the type sludge hopper

• Suitable for storage of sludge cake from filter press, belt filter press and centrifugal device.

• Capacity 1-30m3

• Drive unit: electric, pnuematic or hydraulic, per customer design

• Material of construction: carbon steel epoxy painted SS304/316L

Product Show

Packaging & Shipping

Hot Searches