NaN / 0

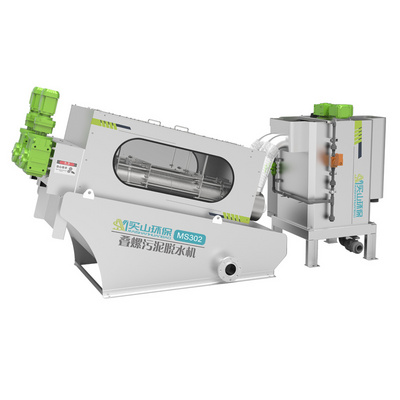

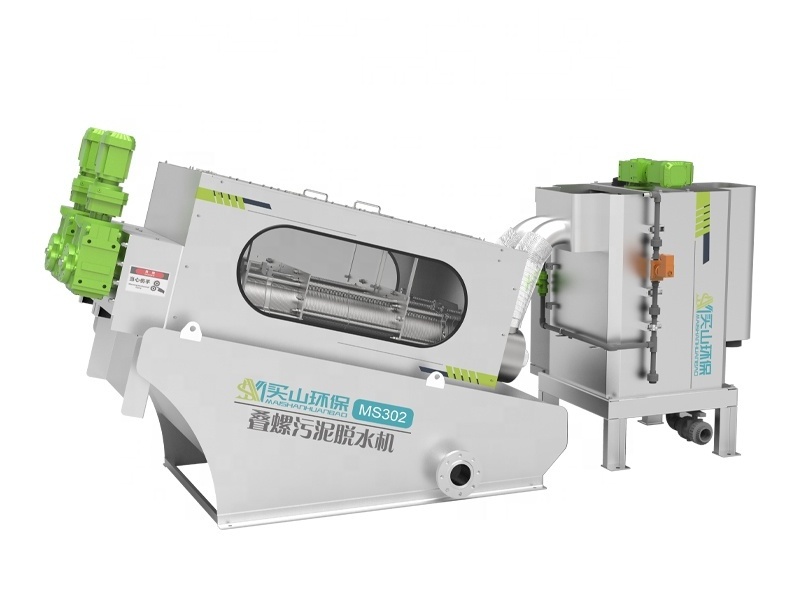

Oily Sludge Treatment Mult-Belt Sludge Dewatering Machinery Wastewater Treatment for Sewage Treatment Plant

Get Latest Price

US$ 3600

≥1 Sets

US$ 3510

≥2 Sets

US$ 3420

≥3 Sets

US$ 3330

≥4 Sets

Quick Details

Place of Origin:

Jiangsu, China

Brand Name:

Maishan

Material:

Plywood wooden crates, 304 Stainless Steel

Weight:

205KG

Product Details

Product Description

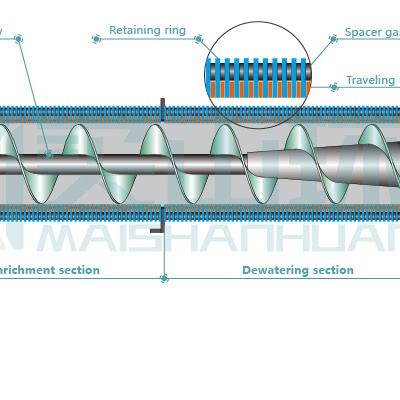

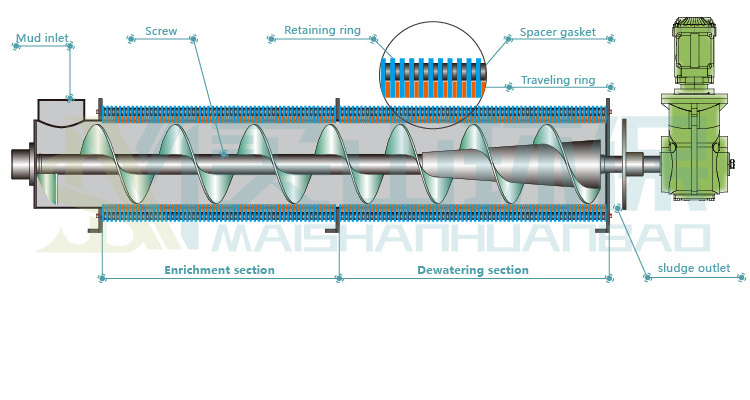

Multi-disc screw press sludge dewatering machine is a new type of solid-liquid separation equipment. The pitch of the screw and the gap between the rings are reduced, which increases its internal pressure, thus realizing dewatering.It can be widely used for sludge dewatering in city sludge, food, beverage, slaughtering and breeding, printing and dyeing, petrochemical, papermaking, leather and other industries, and can also handle oily sludge.

The unique dewatering principle enables the equipment to handle sludge with a concentration of 2000~50000mg/L.Multi-disc screw press wastewater sludge dewatering machine integrates sludge thickening and dewatering, realizing direct dewatering of low concentration sludge.

Product Features

Advantages of our equipment:

1.Designed for activated sludge, excellent at treating oily sludge.

Specification

|

item

|

value

|

|

Condition

|

New

|

|

Applicable Industries

|

Hotels, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Food & Beverage Shops, Other, Advertising Company

|

|

Motor

|

NISSEI or

customizable

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

Hot Product 2022

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

Gearbox, Pressure vessel, Pump, Gear, Bearing, Engine, Motor, PLC

|

|

Place of Origin

|

China

|

|

Province

|

Jiangsu

|

|

Brand Name

|

Maishan

|

|

Material

|

SS 304 / SS 316 / SS 2205

|

|

Weight

|

205 KG

|

|

Size

|

1860*750*1080mm

|

|

Power

|

0.2 kw

|

|

Warranty

|

1 Year

|

|

Productivity

|

6~12KG,DS/h

|

|

Gross Weight (KG)

|

220 KG

|

|

Price

|

Manufacturer's factory price

|

|

Speed of delivery

|

Quick

|

|

Product Quality

|

Industry Benchmark

|

|

Type

|

Sewage Treatment

|

Quality Control

1. Before confirming the order. We will strictly confirm the equipment model, material, color, customized LOGO, and other special customized requirements.

2. We will follow the different stages of production from the very beginning and take video recordings

3. We will check and clean all the equipments, all the parts before packing.

4. Before product delivery, customer can send a quality controller or appointed third party to check the quality.

5. When any problem occurs, we will propose a suitable solution in a short time.

Hot Searches