NaN / 0

High Repurchase Rate Gold Mining Separator Gravity Mineral Processing Equipment Fine-Grained Gold Concentrator Centrifuge

Get Latest Price

US$ 10500

≥1 Sets

US$ 10000

≥2 Sets

Quick Details

Production Capacity:

98%

Place of Origin:

Jiangxi, China

Brand Name:

JXSC

Voltage:

380v or customized

Product Details

Product Description

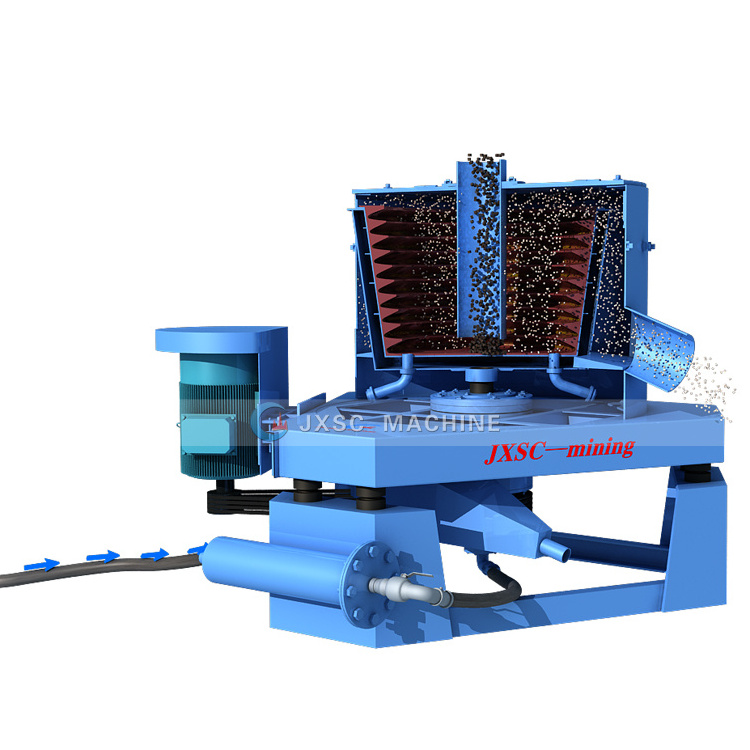

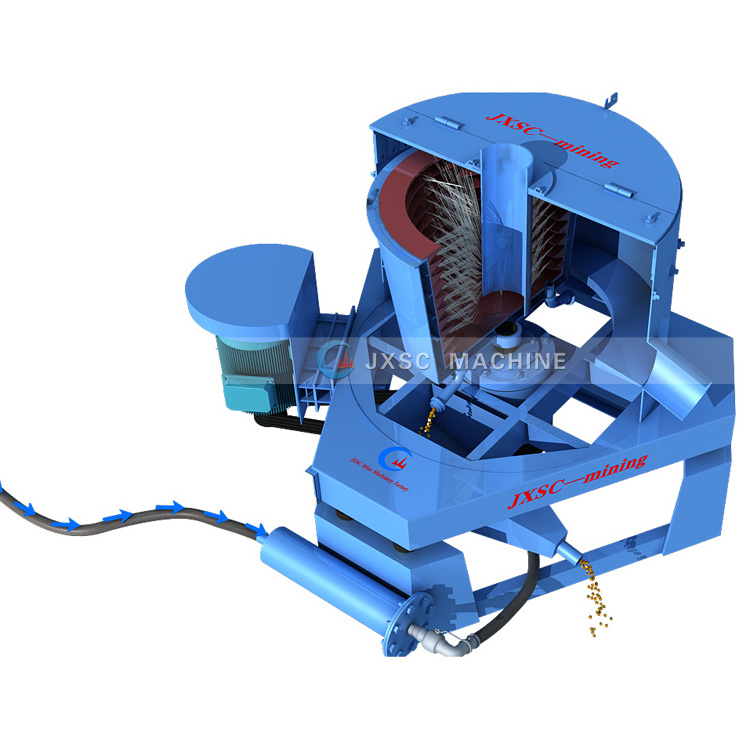

Introduction of Gold Centrifugal Concentrator :

Gold centrifugal concentrator is a machine that was patented in China. It is an efficient machine that is useful in the recovery of free gold in all ranges of particle size. It is most especially useful for recovering fine gold which gets lost during the operation of gravitational concentrators. It is not only used for placer gold mining, but it can also be used for the recovery of natural gold from rocks that are hard, for replacing amalgamation and recovering of gold from the tailings.

Working principle of gold centrifugal concentartor

The rotor of the centrifuge rotates at a high speed at a certain number of revolutions, and the ore slurry is sent to the inner wall of the rotating drum by the ore feeder and the orifice in two places. The ore pulp rotates with the drum at high speed. Under the action of centrifugal force, heavy minerals deposit on the inner wall of the drum and rotate with the drum. At the same time, it needs to continuously give backwash water from the outside to the middle layer of the centrifugal rotor A certain differential speed rotates with the drum. During the rotation, a certain helix angle flows from the feed end to the ore discharge end in the direction of the drum slope to the end, and is discharged through the ore separator at the end, which is the tailings. Work for about 4-6 hours, after the rotor inner wall is enriched with a certain amount of concentrate, stop feeding into the rotor. After the tailings are discharged, the ore discharge separator automatically turns away from the original normal position to prepare to intercept the concentrate. Then, the high-pressure flushing water valve is opened, and the high-pressure flushing water flushes down the concentrate deposited on the inner wall of the rotor. After the concentrate is drained, the equipment is re-opened to work and the cycle is performed.

Features of Gold Centrifugal Concentrator

- High concentrating ratio and high recovery

- Total process automation, steady recovery performance

- Low energy consumptions

- Environmentally friendly (requires no chemical additives or reagents)

- Low water and electricity requirements

- Low operation costs, durable wear parts, minimal maintenances requirements

- Compact design requiring lessspace,easy merged into the existing mining processing

- Quick payback on investment

Technical data

|

Model

|

Capacity (t/hr)

|

Feeding Size (mm)

|

Feeding Density (%)

|

Power Requirement(kw)

|

Cone Rotate Speed

|

Water Required(t/h)

|

Dimension(mm)

|

|

STLB20

|

0.5-1.0

|

0-2.5

|

0-50

|

1.1

|

800

|

1.5-2.0

|

800*560*710

|

|

STLB30

|

2.0-3.0

|

0-4

|

0-50

|

2.2

|

600

|

4.0-6.0

|

1280*1030*1135

|

|

STLB60

|

8.0-12.0

|

0-6

|

0-50

|

7.5

|

460

|

10.0-15.0

|

1850*1550*1600

|

|

STLB80

|

10.0-20.0

|

0-6

|

0-50

|

15

|

400

|

17.0-25.0

|

2300*1800*2200

|

|

STLB100

|

50-100

|

0-6

|

0-50

|

18

|

360

|

40.0-60.0

|

2400*2400*2250

|

Application of gold centrifugal concentrator

Gold Centrifugal Concentrator used for Alluvial gold Washing Plant:

1) Flowchart of raw materials with sticky clay

100tph full set Alluvial Gold Wash Plant Project in Ghana

We designed flowchart based on customer's gold mine site details.

We supplied full set gold mining equipment for this project: vibrating feeder, trommel scrubber washing machine, gold centrifugal concentrator, sluice box and shaking table and gold refinery machine.

We supplied full set gold mining equipment for this project: vibrating feeder, trommel scrubber washing machine, gold centrifugal concentrator, sluice box and shaking table and gold refinery machine.

40-50 TPH Mobile Alluvial Gold Wash Plant For Korean Project

JXSC factory supplied the complete mobile gold wash plant for this customer from Korea. The complete equipment including: trommel scrubber+centrifugal concentrator+shaking table+sluice box+gold smelting furnace.This plant is very suitable for processing alluvial gold ore with sticky clay and capacity is within 50tons per hour.

Its advantage is easy move to other places for extraction gold.Easy operation,low investment cost,high gold recovery rate.

Its advantage is easy move to other places for extraction gold.Easy operation,low investment cost,high gold recovery rate.

3D Flowchart of 40-50 TPH Mobile Alluvial Gold Wash Plant

Advantages of this flowchart:

1. High gold recovery ratio

2. The whole plant easily move

3. Suits for any type of alluvial gold ore,especially suits for raw ore with heavy clay or sticky clay

2) Flowchart of raw materials without sticky clay

40TPH alluvial gold wash plant in Mali

Raw ore conditions:

1. Raw materials dont contain sticky clay,so just use trommel screen ok.

2. Gold grain size range is 0-5mm.

3. Input capacity is 40 tons per hour

4. Max feeding size of raw ore is 100 mm

Equipment list provided by JXSC:

1. Trommel screen

2. Gold centrifugal concentrator

3. Sluice box

4. Shaker Table

5. Mercury amalgamation

6. Distiller retort

7. Gold smelting furnace

Feedbacks from customer

The whole system is high efficient on separating gold from sand soil.

Packing & Delivery

Packing:

Small models will be packed into wooden case.

Small models will be packed into wooden case.

Big models will be packed with iron stand,then loading to container directly

Shipping method: By Sea

Shipping method: By Sea

About Company

Engineer Field Installation&Commission

Our customer

FAQ

1.How is the quality of your products?(mining equipment/machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will do a test on every machine before delivery.

2.Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description or promise we made before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before factory delivery, which is international trade practice; Finished product pictures will be provided to customers before delivery.

Answer: Our products are manufactured strictly according to national and international standard, and we will do a test on every machine before delivery.

2.Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description or promise we made before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before factory delivery, which is international trade practice; Finished product pictures will be provided to customers before delivery.

Hot Searches