NaN / 0

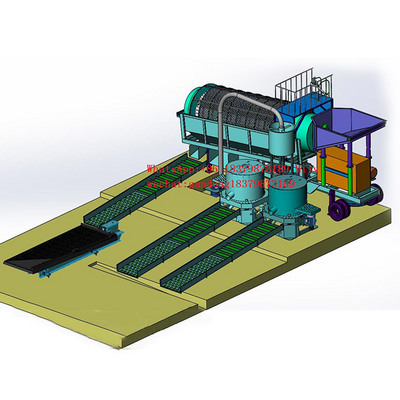

centrifugal concentrator gold laboratory mining separator gold concentrate machine concentrator centrifuge

Get Latest Price

US$ 8800

≥1 Sets

Quick Details

Production Capacity:

90%

Place of Origin:

Jiangxi, China

Brand Name:

GANDONG

Voltage:

220V/380V

Product Details

Centrifugal concentrator gold laboratory mining separator gold concentrate machine concentrator centrifuge

Product Description

Centrifuge is the latest gravity dressing equipment. The principle of this equipment is to use centrifugal force to expand the gravity of mineral particles to separate heavy particles from light particles. The key component is a conical enrichment cone that is driven by a motor to rotate at high speed and surrounded by pressurized recoil.

This centrifugal concentrator has obtained invention patents in China. The device has a significant effect on monomer gold in different particle size ranges. The ore dressing test proved that the sand gold recovery rate was above 99%, and the selection ratio reached 1000 times. Especially when recovering the natural gold in the vein gold mine, when the grinding particle size is less than 0.074 mm, the recovery rate of the monomer gold can reach 98% or more, and the recovery rate of the monomer gold for 0.04 mm is over 97%.

Our company has developed a centrifuge automatic discharge system for the operation of the old model products, which is cumbersome and wasteful, and wastes labor. It can realize automatic operation. This is also one of our strengths,Other than this,we use soft connection in the shock absorption part, which can effectively reduce the adverse effects caused by equipment vibration, improve the accuracy of mineral processing and increase the service life of the equipment.

Technical Specifications

|

Model |

STLB20 |

STLB30 |

STLB60 |

STLB80 |

STLB100 |

|

Feeding Capacity (T/h) |

0-0.6 |

2-3 |

8-12 |

40-45 |

60-80 |

|

Fluidization Water Required (m3/h) |

2-3 |

3-5 |

7-10 |

30-36 |

50-60 |

|

Slurry Water Required (m3/h) |

1.5-4 |

5-7 |

8-12 |

40-45 |

60-80 |

|

Feeding Density (%) |

0-50 |

0-50 |

0-50 |

0-50 |

0-50 |

|

Feeding Size (mm) |

0-1 |

0-3 |

0-5 |

0-5 |

0-6 |

|

Concentration Cleaning Up Cycle |

Vein gold 1-3 Hours Placer gold:2-6 Hours |

||||

|

Concentrate Weight (Kg) |

2 |

3-5 |

10-20 |

40-50 |

70-80 |

|

Power Requirements (Kw) |

0.75 |

1.5 |

4 |

11 |

18.5 |

|

Approximate Shipping Weight (Kg) |

205 |

380 |

1100 |

2300 |

3700 |

|

Approximate Crated Shipping Dimensions (mm) |

914×700×900 |

1160×885×1165 |

1820×1450×1700 |

2520×1900×2020 |

2713×2169×2267 |

Main Features

1.High concentrating ratio and high recovery;

2.Steady recovery performance;

3.Center discharge design for fast,secure concentrate removal;

4.Environmentally friendly(requires no chemical additives or reagents);

5.Low water and electricity requirements;

6.Low production costs, durable wear parts, minimal maintenance requirements;

7.Compact design requiring less space, easy merged into the existing mining processing;

8.Quick payback on investment, typically lass than half year;

Aim at solve discontinuous work, complicated stop washing operations and waste manpower etc these shortcomings of older model products, our company developed automatic discharging system, now our new concentrators can be fully automated. No longer needed stop the concentrator and wash concentrates by manpower, only needed push start and stop button on the antomatic control system to complete all works. Because whole process is closed operation, it can avoid man-made concentrate loss. Besides, our concentrator adopt soft materials at shock-absorbing places, it can effectually decrease negative effects issued from the vibration, and increase of service life.

Inner material: stainless steel 316L,polyurethane,SKF beraing

Application shows that the recovery can be as high as 99%, and the concentrating ratio is up to 1,000 times. In recovering the natural gold in lode ore with size -0. 074mm, the gold is up to 98%, For 0.04mm in particle size, the gold recovery is 97%.

Why Choose Us

Jiangxi Well-tech International Mining Equipment Co.,Ltd. (Gandong Mining Equipment) is a large mineral processing service company specialized in designing, manufacturing, installing and debugging of mining equipment as well as providing flow sheet design and course training of mineral processing.

Our company covers an area of 48,000 square meters, the workshop covers 20,000 square meters, we have various large modernized machinery process facilities, professional engineering team and installation team.

Now our company is the largest manufacturer and exporter of gravity dressing equipment in China.

Global Business Customs

Our customs are all over the world,so far,we sold 5 coutinents,more than 50 countries.

Pre-Sales Service

Inquiry and consulting support.

Sample testing support.View our Factory.

After-Sales Service

1.Video technical support

2.Field installation, commissioning and training

3.Field maintenance and repair service

4.Online support

5.Engineers available to service machinery overseas.

FAQ:

Q:You are factory or trade company?

A:We are the biggest grav it y separator machine manufacturer in China.we have 6 modem

workshops,1sample test workshop,1office build.

Q:If your company can provide whole line machine?

A:Yes,From washing to get final gold bar.

Q:What's capacity you can provide?

A:All machine can customization,we can provide from 1t/h-100t/h.

Q:If can arrange engineer come to worksite for installation?

A:Yes.

More details,please don’t hesitate to Contact us,you can send us inquiry as below, we will reply you within 24hours.

or add My Wechat: 18379873189 or WhatsApp:+86 18379873189,Thanks for your time!

Hot Searches