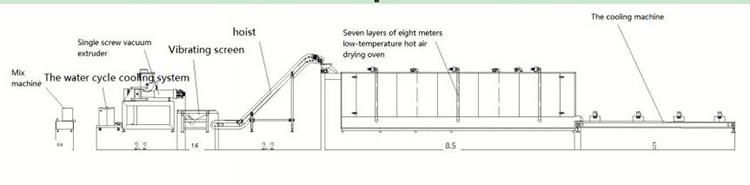

Steam Type Low Temperature Hot Air Dryer

Conveyor belt:304 stainless steel,braided mesh belt,7 floors

Length: Each layer is 8 meters long and the total conveying distance is 56 meters Width: 1 m

Conveying speed: 0-6 meter/ min, frequency control

Electrical and control: independent button type control cabinet