NaN / 0

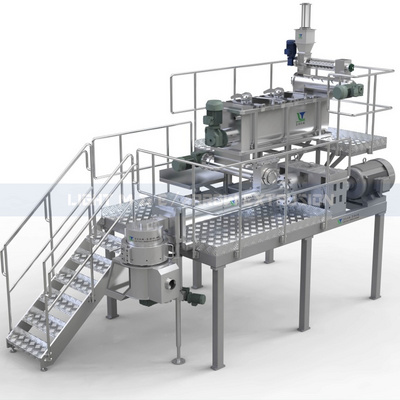

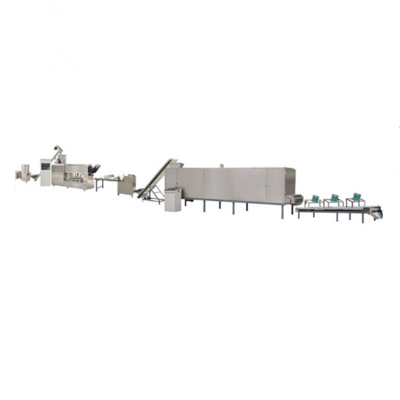

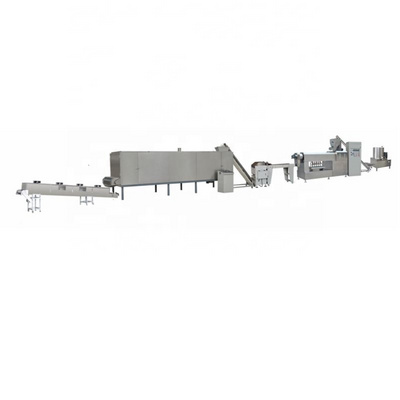

Click Long Life Time Macaroni Spaghetti Pasta Production Line

Get Latest Price

US$ 135000

≥1 Sets

US$ 130000

≥5 Sets

Quick Details

Place of Origin:

Henan, China

Performance:

Long Life Time Macaroni Spaghetti Pasta Production Line

warranty period:

1 year

Main material:

stainless steel

Product Details

Click Long Life Time Macaroni Spaghetti Pasta Production Line

Product Description

Product Description

Roll width : 350mm capacity: 1.5T/8h

Main configuration

| Serial NO. | Product name | Model | quantity | Remark |

| 1 | alkali mixing and measuring | YSH10 | 1 unit | Power:0.75kw, volume:120L/unit, |

|

the surface touched with the water is SS304 |

||||

| 2 |

double- speed flour mixing machine |

HMJ200 | 1 unit |

Motor power 9/11kw,200kg/batch, door opening by manual, the surface touched with flour is SS304 |

| 3 | Disk-type feeder | PS200 | 1 unit |

Motor:4kw,tray size: φ1800mm×410mm the surface touched with flour is SS304 |

| 4 |

Compound- continuous rolling machine |

MT7-50 | 1 unit |

Roll width:350mm, motor power:5.5kw+5.5kw (frequency conversion timing), 7 pairs of steel roller-cold-hard alloy, frame (two sides)is SS201,the Dia. of the roller is: φ180mm×2,φ240mm×2, φ180 mm×2,φ162mm×1 |

| 5 | belt type cabinet | SX6 | 2 units |

the surface touched with flour is SS304,aluminum glass door |

|

Specification:750*850*1400mm, six roll of noodle can be put in |

||||

| 6 |

Dehydration sterilization machine |

TS800 | 1 unit |

Main driven 1.5kw (frequency conversion timing), the length of body is 16 meters, surface touching food is SS 304, |

| Heating power~20kw, | ||||

| fan0.55kw×6 | ||||

| 7 | electrical control system | BPT-1 | 1 set |

operation adopts frequency conversion timing |

noodle production line, the main process of the equipment using frequency control, photoelectric tracking, PLC program Control, to achieve a full range of synchronous coordination control, cut the number of knives, block weight can be reduced in the non-stop dynamic Whole, frying temperature control, and noodles using elliptical paddle two-axis two-speed technology to add more water, materials and moisture Combined with more uniform; curing machine using W-type double pot technology , the basic guarantee of the dough aging;9 pairs of cold alloy roll; noodles steamed after the use of immersion flavor technology; equipment and food contact surface are used Stainless steel and non-toxic materials, in line with food hygiene standards.

Features

1 .High automation ,PLC controlled

2. High efficiency ,saving man power

3.Capacity: from 2.5-20tons per 8hours (based wheat flour consumption), can be customized

4.Made Material :main used SSL

5.Easy operation, repair and maintenance

Advantage Of Noodle Production Line:

1. Practical, energy-saving, high efficiency, easy to clean and repair, low fault rate

2. Easy to use

3. The machine is approval of the national hygienic standards, it is very safe and healthy

4. The machine can work separately or with production line

5. Customers can adjust the size to meet with different needs

For More Details , Please Click Send On The Right → → → →

Click Long Life Time Macaroni Spaghetti Pasta Production Line

Click Long Life Time Macaroni Spaghetti Pasta Production Line

For More Details , Please Click Send On The Right → → → →

Hot Searches