NaN / 0

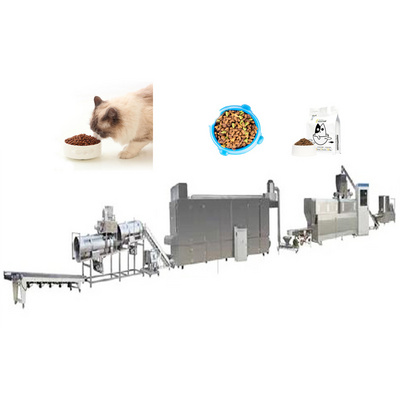

industrial dog treat extruder machine pet food processing production equipment pet treats extruding line

Get Latest Price

US$ 10000

≥1 Sets

US$ 9000

≥2 Sets

Quick Details

Marketing Type:

New Product 2023

Place of Origin:

Shandong, China

Brand Name:

Bright, Bright

Voltage:

Customer's Requirement

Product Details

Related products

Product Description

industrial dog treat extruder machine pet food processing production equipment pet treats extruding line

introduction:

Pet treats processing line takes starch as raw materials with scientific configuration and was extruded from coextruder machine ,it can be made into many kind of shapes such as stick, bone ect.This kind of dog food not only provide protein fat vitamin nutrition for dogs, but also satisfy the dog nature hobby.It has following features: strengthen teeth, clean mouth and teeth, the products can be in many shapes, like twist, bi-color, core-filling and so on.

Flow chart :

1)Single color Dog chews machine

Mixer → Screw conveyer→Single-screw extruder → Cooling conveyor → Cutter machine

(2)Double color dog chews machine

Mixer *2→ Screw conveyer*2→Single-screw extruder*2 → Cooling conveyor → Cutter machine → elevator → Dryer

Flow chart diagram:

Our engineer could design the layout drawing according to your dimension of the factory for the dog chews machines

Machine parameters

|

Model

|

Installed Power

(kw)

|

Power Consumption

(kw) |

Capacity

(kg/h)

|

Dimension

(m)

|

|

100 processing line

|

47.25

|

40

|

120-180

|

17*1.2*2.2

|

|

120 processing line

|

94

|

85

|

200-300

|

20*1.5*2.2

|

Main Features

1).Our processing line adopt international advanced technology.

2).we can adjust the cutter speed and the dies to get the different diameter and the length product

3).The Electric heating device system can control the temperature accurately

4).High temperature and high pressure can kill the salmonellosis andbacterial infections.

5).The processing line can produce both floating and sinking fish feed.

Raw material:

Materials: Corn powder, wheat flour,fish powder, bone powder,meat,glycerin,starch etc and water.

Sample of pet chew food:

Equipment list in the pet chew production line:

mixer→screw conveyor→single screw extruder →cooling machine →cutting machine → air

conveyor→dryer→packing machine

1)mixer of Good Pet Treats Dog Chews Bone food making Extruder Machine

|

Name

|

Mixer

|

|

Usage

|

To mix the raw materials evenly, fast speed, no leakage.

|

|

Type

|

including Single axle and double shaft mixer

|

|

Motor

|

3kw, 4kw, 7.5kw etc.

|

|

Capacity

|

20kg/time, 50kg/time, 100kg/time, 200kg/time, 500kg/time etc.

|

|

Material

|

stainless steel, carbon steel

|

2)extruder of Good Pet Treats Dog Chews Bone food making Extruder Machine

|

Name

|

Single screw extruder

|

|

Usage

|

To extrude the raw materials and make them to the required shape and size of the dog food pellets by mould

|

|

model

|

DSE100,120,135

|

|

Motor

|

30kw, 55kw, 75kw, 90kw, 110kw etc.

|

|

Capacity

|

100kg/h to 10 ton/h

|

|

Material

|

Screw materials 38CrMoAl

stainless steel, carbon steel |

3)cutting machine of Good Pet Treats Dog Chews Bone food making Extruder Machine

|

Name

|

Cutting

|

|

Usage

|

Use a knife on the machine to pet chew into pieces, adjustable speed

|

|

model

|

QDJ50

|

|

Motor

|

0.75kw

|

|

Capacity

|

100kg/h to 10 ton/h

|

|

Material

|

stainless steel

|

4)oven of Good Pet Treats Dog Chews Bone food making Extruder Machine

|

Name

|

Dryer (oven)

|

|

Usage

|

the expanded food go through the "s" passage, to be dried to increase the self life.

|

|

Type

|

electrical, steam, gas fired, diesel fired heating type

|

|

Motor

|

KX-3-5, KX-5-5, KX-5-8, KX-5-10, KX-7-10 etc.

|

|

Capacity

|

100kg/h to 10 ton/h

|

|

Material

|

stainless steel, carbon steel

|

5)packaging of Good Pet Treats Dog Chews Bone food making Extruder Machine

|

Name

|

Packaging machine

|

|

Usage

|

To pack the dog feed with required weight

|

|

Flowing Process

|

Manual Bag placing→Automatic filling→Automatic weighing→ Automatic bag conveyor→Automatic bag sewing or heat sealing

|

|

Weight range

|

1-5kg/bag, 5-25kg/bag, 25-50kg/bag

|

|

Material

|

stainless steel, carbon steel

|

|

Type

|

Automatic

|

Why choose us

Our Service

1.) Consultation service before, during,and after sales;

2.) Project planning and design service;

3.) Debugging of equipment until everything is functional;

4.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

5.) Training of equipment maintenance and operating personally;

6.) New production techniques and formulas;

7.) Provide 1 year complete warranty and life-time maintenance service.

Company&Customer

Jinan Bright machinery company

is a special extruder machinery manufacturer. Our company have

13 years

production experience.The average sales amount is

40 million RMB

. Exported to Britain,Ukraine,Thailand,Brazil and other more than

100 countries

.

FAQ

Q: Are you a trade company or a manufacturer?

A :we are a manufacturer, welcome to visit and check the machine to my factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: 30% T/T in advance ,balance before shippment.

Q: How about the after-service?

A: We will send 1 engineer to the buyer's factory for a 10-day period installation and training to the operators.

Q:do you supply any formula to buyer?

A:yes, we supply formula to buyer.

Packing &Delivery

1.Use anti-rust oil to wipe the equipment for Pet Treats Dog Chews Bone food making Extruder Machine

2.air cushion film packaging equipment for dog treat snack machine

3.with a wooden box for the final step of packaging.

Hot Searches