With the rapid development of urban rail transit projects, the U-Beam is widely used on viaduct roads. Currently, U girder is one of the most innovative viaducts used in urban rail transportation. It has the advantages of noise reduction, low building height, high space utilization, and good appearance. With the advancement of technology, construction methods have changed from cast-in-place to precast hoisting. Use either double crane lifting or gantry crane lifting to hoist the U girder.

Our key projects

Boyoun is a professional enterprise that designs and manufactures U-Beam formworks. The U-Beam has been successfully applied to Shanghai Urban Rail Transit, Qingdao Intercity Rail, Pakistan Light Rail, Dubai Light Rail, etc.

Specification

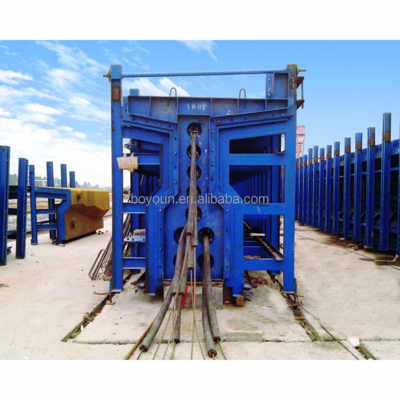

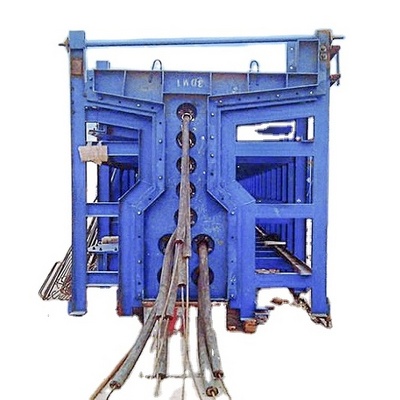

Precast U girder formwork structure: outer side formwork, inner formwork, bottom formwork, support lead screw, jack, work platform, Vibrator, crawling ladder, blanking plate, etc.