NaN / 0

Best refrigerated air dryer machine for air compressor

Get Latest Price

US$ 350

≥1 Pieces

Quick Details

Model NO:

SDLF-3

Transport Package:

Carton or wooden cases

Trademark:

Shanli

Origin:

China

Product Details

Applicable working conditions

Max inlet temp:60°C

Environment temperature range:5°C-50°C

Pressure range:0.6-1.6Mpa ( 0.5-12Nm³/min )

0.6-1.0 Mpa ( 15Nm³/min and above )

Pressure dew point:2℃~10℃

Cooling mode:air cooled

Cryogen:0.5~2 Nm/min is R134a, 3~12Nm3/min is R410a,

15~80Nm/min is R407C, 80 Nm/min and above is R22

Design working conditions

Inlet air temperature: 38°C

Ambient temperature: 38℃

Working pressure:0.7Mpa

Cooling water temperature: ≤32℃

Working principle

the amount of water vapor in the compressed air is determined by the temperature of the compressed air: under the condition that the pressure of the compressed air is basically unchanged, reducing the temperature of the compressed air can reduce the content of water vapor in the compressed air, and the excess water vapor will condense into liquid. According to the corresponding relationship between the saturated steam pressure and temperature of water, the freezing dryer uses the refrigeration device to cool the compressed air to a certain dew point temperature, release the contained water, and discharge the water through the steam water separator and electric drainer, so as to dry the compressed air.

Product Characteristics

Ensure the normal operation of the equipment at the ambient temperature of 50℃;

0.5-80 cubic meters use environmentally friendly refrigerant; use a three-in-one plate or plate-fin heat exchanger ,collecting three functions of the regenerator, the evaporator and the gas-liquid separator , with good heat exchange effect, compact and beautiful structure; modular refrigeration components. Convenient for disassembly and repair, strong replaceability;

R22 refrigerant and tube heat exchanger are used for more than 80 cubic meters; the gas-liquid separator adopts a patented three-stage separation method of "direct collision separation , low-speed centrifugal separation and stainless steel wire mesh demisting separation", which will remove 99.9% of the liquid The moisture is separated from the cooled compressed air to prevent the secondary evaporation of moisture and ensure the low dew point quality of the finished gas;

The refrigeration compressor adopts DANFOSS, FUSHENG, PANASONIC, BTZERO, COPELAND, HIGHLY, etc. fully enclosed or semi- enclosed refrigeration compressors, which have stable operation, low noise, high COP, reliable performance, and long power- saving life;

Refrigeration control components adopt the world's advanced refrigeration components like DANFOSS, EMERSON,SPORLAN and other companies;

Real-time display of operating parameters;

Air-cooled refrigerated compressed air dryer (plate fin type)

Item

Model | Air capacity | Voltage | Fan Power | Air connection pipe diameter | N.W | L | W | H | Air volume |

SDLF-0.5 | 0.65 | 220 | 40 | G1" | 34 | 400 | 560 | 730 | 410 |

SDLF-1 | 1.2 | 220 | 40 | G1" | 36 | 400 | 560 | 730 | 410 |

SDLF-2 | 2.5 | 220 | 50 | G1" | 45 | 520 | 640 | 890 | 820 |

SDLF-3 | 3.6 | 220 | 85 | G1" | 54 | 520 | 640 | 890 | 1000 |

SDLF-4.5 | 5.0 | 220 | 165 | G1-1/2" | 60 | 540 | 700 | 1000 | 1850 |

SDLF-6 | 6.8 | 220 | 165 | G1-1/2" | 65 | 540 | 700 | 1000 | 1850 |

SDLF-8 | 8.5 | 220 | 170 | G2" | 76 | 610 | 900 | 1070 | 3700 |

SDLF-10 | 10.9 | 380/220 | 150 | G2" | 88 | 610 | 900 | 1070 | 3700 |

SDLF-12 | 12.8 | 380/220 | 150 | G2" | 88 | 610 | 900 | 1070 | 3700 |

SDLF-15 | 16 | 380/220 | 380 | DN65 | 255 | 1170 | 920 | 1420 | 7600 |

SDLF-20 | 22 | 380/220 | 380 | DN65 | 260 | 1170 | 920 | 1420 | 7600 |

SDLF-25 | 26.8 | 380/220 | 460 | DN80 | 290 | 1170 | 920 | 1420 | 9000 |

SDLF-30 | 32 | 380/220 | 840 | DN80 | 350 | 1400 | 1200 | 1600 | 12500 |

SDLF-40 | 43.5 | 380/220 | 1100 | DN100 | 485 | 1400 | 1200 | 1600 | 15000 |

SDLF-50 | 53 | 380/220 | 920 | DN100 | 800 | 1600 | 1200 | 1600 | 18000 |

SDLF-60 | 67 | 380/220 | 920 | DN125 | 1000 | 1600 | 1400 | 1650 | 18000 |

SDLF-80 | 90 | 380/220 | 2200 | DN125 | 1280 | 1800 | 1500 | 1770 | 30000 |

Package and Shipment

● Packing details: Wooden crate pallet plus foam board and bubble film, Full closed wooden case. 1pcs/each package (for stationary desiccant air dryer)

● Transportations: sea transport, rail transport, air transport, road transport, LCL/ FCL container transport or as requested

● Trade terms: FOB, CFR, CIF and EXW, DDP, etc.

● Delivery time: in 20 days after receiving deposit (customized machines not included)

Company Information

● Hangzhou Shanli Purify Equipment Corp., was formed in 1997, as a compressed air solutions company.

● The workshop at integrated engineers and contractors has a dedicated team, which is continuously engaged in upbringing of new technologies for greater efficiency.

● The company was involved in supplying of refrigerated air dryers, desiccant air dryers, compressed air filters, oil water separators and water chillers as a manufacturer, exporter and supplier.

Advantage

1. Quality:

● Certification: CE, ISO-9001, ISO-14001 and 26 patents to ensure unmatched quality of our product assortment.

● Stringent quality control mechanism: updating the involved technology as per prevailing international standards;

● Stable performance: using premium grade raw material from highly reputed manufacturers, like Danfoss, Emerson, Performer, Bitzer, Fusheng, Sprolan;

2. Customer:

● Some of major cooperated customers (from our wide range of customers ) have been enlisted below for reference:

S.NO. VALUED CUSTOMERS S.NO. VALUED CUSTOMERS S.NO. VALUED CUSTOMERS

1 Atlas Copco 2 BOGE Kompressoren 3 Ingersoll Rand

4 CompAir Air Compressors 5 Sinopec Group 6 Sullair Asia

3. Scale:

● Shanli has become one of largest manufacturers in purifying industry of China with annual sales turnover USD 22 million.

● Shanli has a wide range of customers who have full faith in our service delivery, warranty, quality and workmanship.

Product Applications

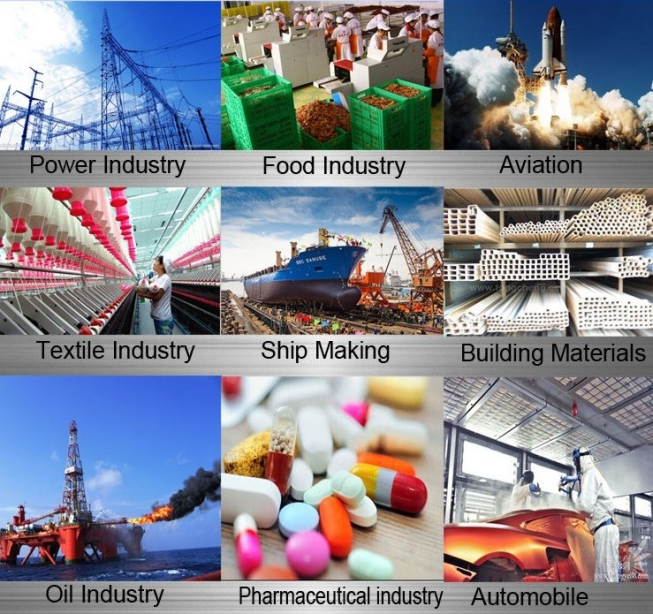

There are still some areas and applications where Shanli air dryers can be used, such as power construction, packing food, making ship, cleaning medical molding,removing EDM recast and discoloration, finishing and texturing injection mold cavities, cleaning orifices in turbine blades, engraving optical lenses,cleaning and preparation of semi-precious stones and jewelry, etc.

Product Applications

There are still some areas and applications where Shanli air dryers can be used, such as power construction, packing food, making ship, cleaning medical molding,removing EDM recast and discoloration, finishing and texturing injection mold cavities, cleaning orifices in turbine blades, engraving optical lenses,cleaning and preparation of semi-precious stones and jewelry, etc.

Explore More Products

Hot Searches