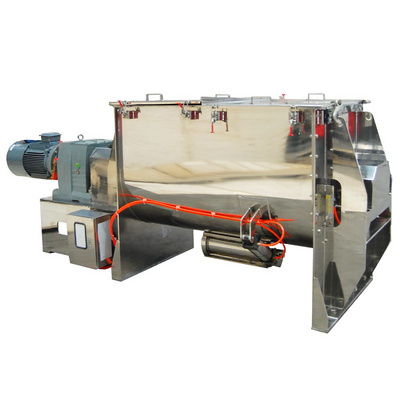

With fly cutters to break the cakes during mixing;

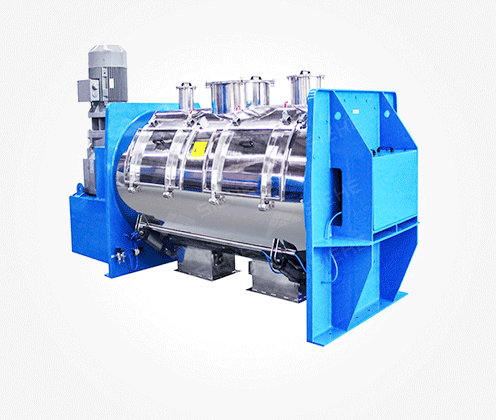

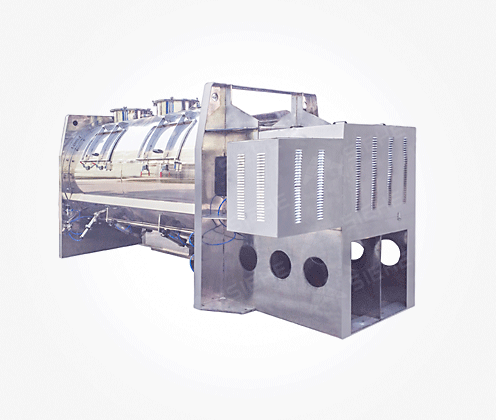

Plough agitator and fly cutter

with high speed,with higher mixing efficiency

with high speed,with higher mixing efficiency