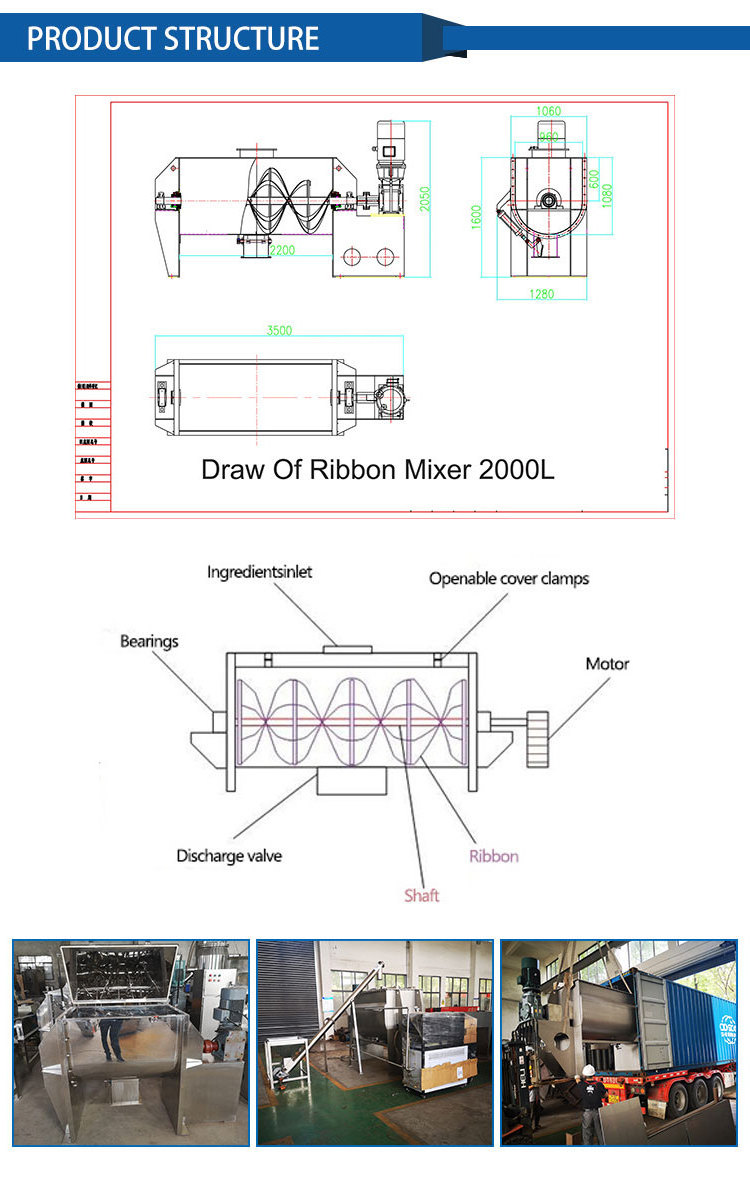

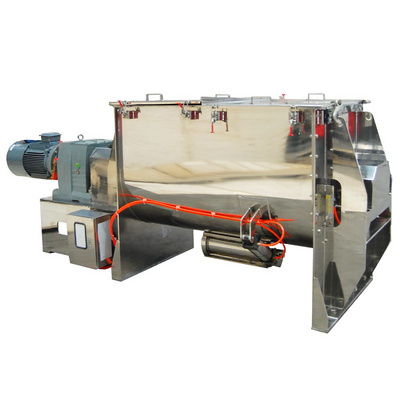

big open structure, using pneumatic materials has the advantages of fastdischarging, no residual;Adopt high fineness of materials or semiliquid materialusing manual buterly valve or pneumatic buterly valve. Configurable heating orcoling jacket, Heating mode has electric heating and heat conduction oil heatingin two ways. Cooling process can be directly to infuse water jacket and clip hotswap area is large, the cooling speed. Small type mixer adopts reducer directmode, simple structure, high operating rlialily.maintenance is convenient. Largenumber mixer adopts pulley drive the cycloid speed reducer drive, belt transmis-sion of elastic connection has the advantage of the

overload protection whendriving part.

Material can be carbon steel, manganese steel, ss304, 316L and 321; besides, different material can also be used in combination.Material is different between the part contact with the raw material and the parts don’t contact with the raw material.Surface treatment for stainless steel include sandblasting, wiredrawing, polishing, mirror polishing, all can be used in different parts of a mixer.

The driven unit, power and output speed are varied according to different raw material, starting method, and processing.Options for motor: general motors, explosion-proof motors, variable frequency motor, high efficiency and energy saving motor.Commonly used reducers: R-series, K-series, and F-series gear box; cycloidal reducer, universal gear reducer, planetary gear reducer. Commonly motor-gearbox connection: direct connection, pulley connection, hydraulic coupler connection.

Different main shaft agitators can be equipped according to the properties of raw materials.Materials commonly mixed are: different kinds of powder to be mixed with each other,batches mixing for the same material, powder with a small quantity of liquid, liquid with some powder, like slurry, thickening or diluting slurry, granule with powder, granule with granule, or agglomerated material breaking and mixing, and cooling or heating.The main shaft agitator could be: inner and outer ribbon, paddle and ribbon, disconnected ribbon,and shaver-shaped agitator.

Standard valve for horizontal mixer is pneumatic planar flap valve. When close the valve, the planar flap match the mixing barrel perfectly, this makes no mixing dead zone and better mixing effect.The drive types of valve are Manual, pneumatic, and electric.Valves for consideration: powder spherical valve, cylinder valve, plum-blossom dislocation valve, butterfly valve, rotary valve etc.

Various inlets on the top cover of the barrel can be designed according to different situations.They can be used as man hole, cleaning door, feeding hole, vent, and dust collecting hole. The top cover can be designed as fully-opened lid for easy cleaning.

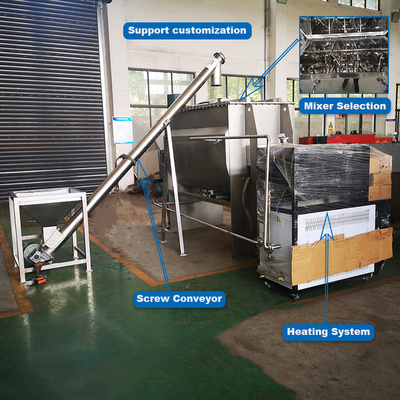

Mixer is frequently equipped with many auxiliary components, like steam coil jacket, honeycomb pressure jacket, medium circulation jacket, sampling valve, high speed chopper,temperature sensor, weighing system, dust removal system and so on.Different heat medium requires different jacket, it can be used for heating and cooling, while, the temperature should be within 250 Celsius degree.If a small quantity of liquid is required during mixing, spraying or

atomizing unit is necessary in order to mix the liquid evenly with the main ingredient. The liquid-adding system is basically composed by the three parts: pressure source, liquid storage pot and spraying nozzles.